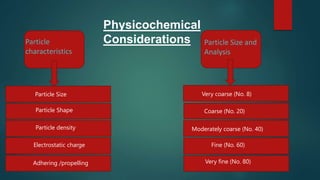

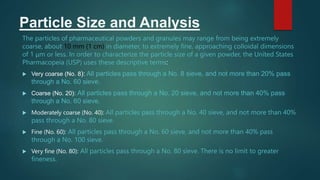

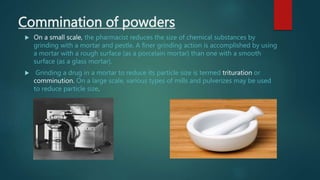

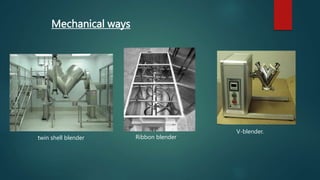

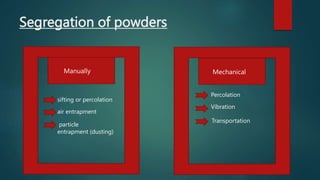

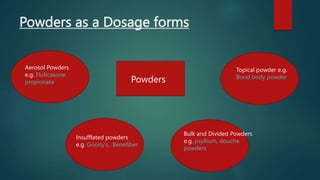

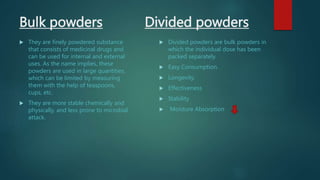

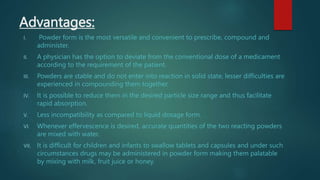

This document discusses solid dosage forms in pharmaceutics, specifically focusing on powders, their characteristics, and their use in drug delivery systems. It covers topics like particle size classification, methods of powder mixing, and the advantages and disadvantages of using powders as a dosage form. Examples of powder applications include topical powders, aerosol powders, and bulk powders, highlighting their stability and versatility compared to other forms.