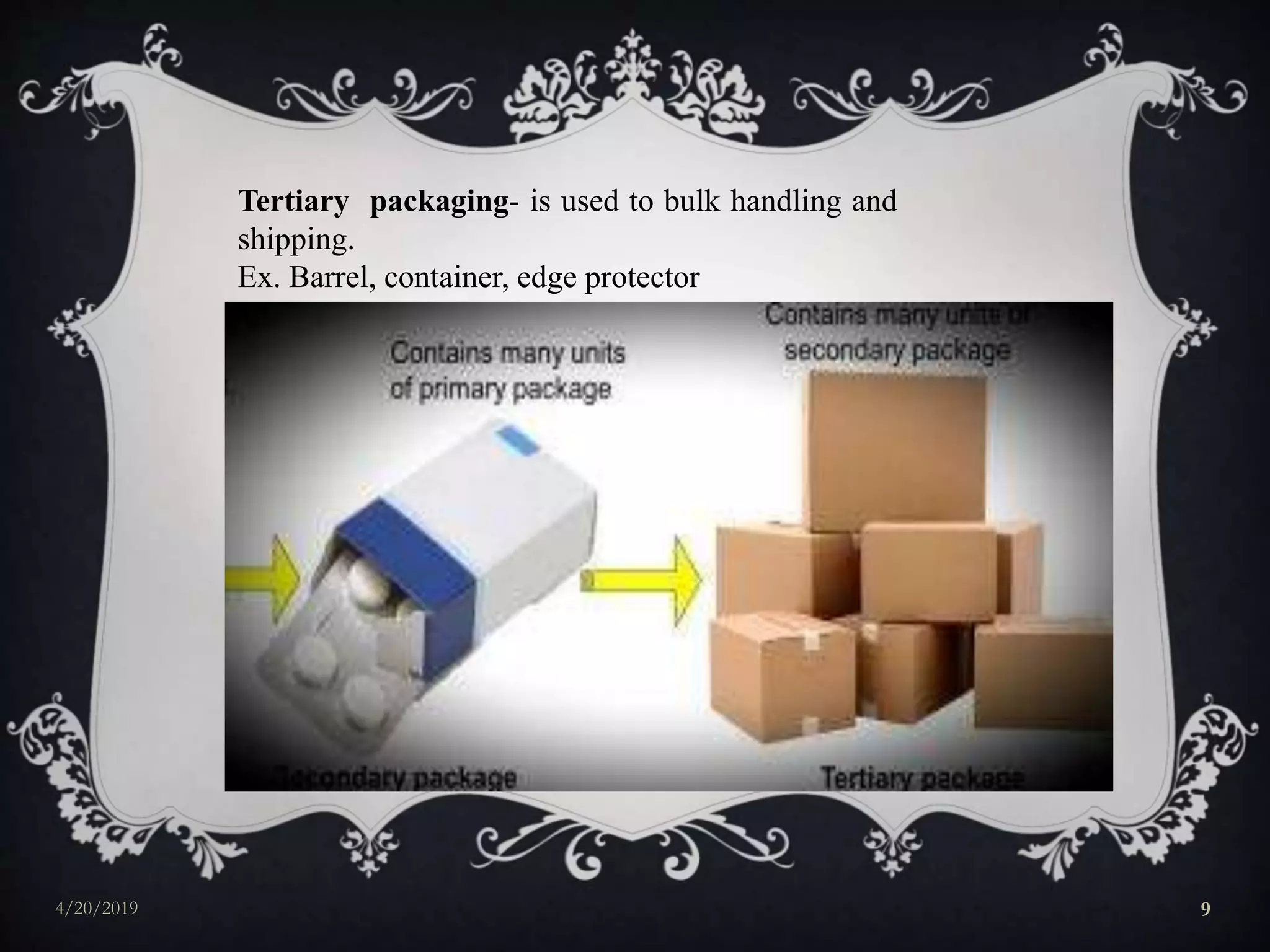

Mr. Sawankumar R. Padavi presented on pharmaceutical packaging at Anand Pharmacy College. The presentation covered the introduction to packaging, ideal packaging requirements, functions of packaging, types of packaging including primary, secondary and tertiary, packaging testing, common packaging materials like glass, plastic, rubber, metal and paper, how to select appropriate packaging materials, and concluded with references. The functions of pharmaceutical packaging are to identify and protect products, facilitate use, promote products, and provide convenience. Common packaging materials include glass, plastic, rubber, metal and paper/cardboard.