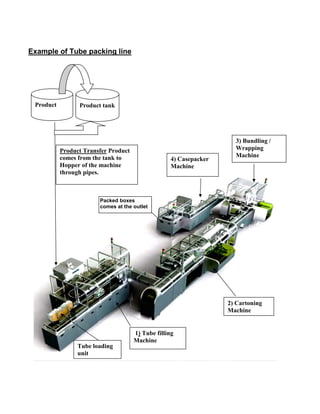

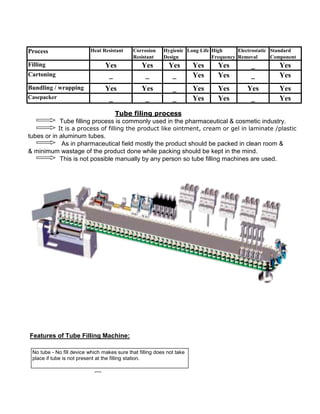

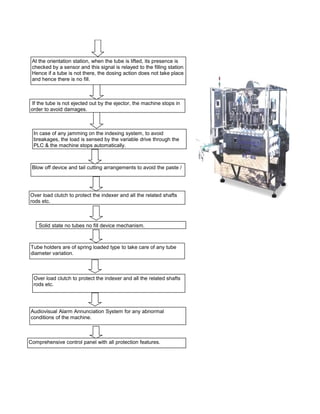

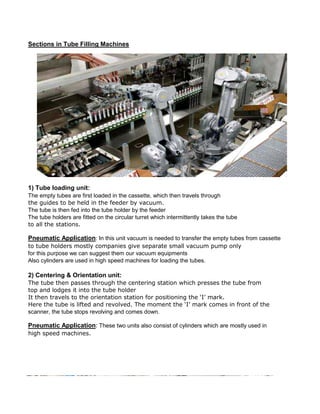

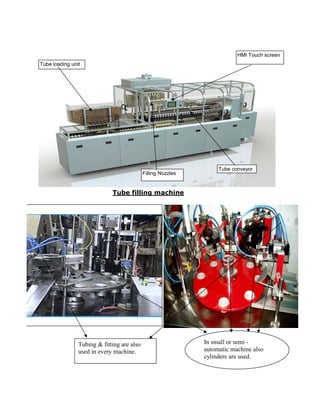

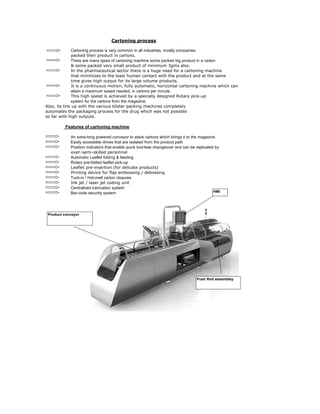

The document provides information about pharmaceutical packaging processes and machinery. It discusses tube filling, cartoning, bundling/wrapping, and other packaging processes used in the pharmaceutical industry. Tube filling machines use pneumatic components like cylinders and solenoid valves to automatically fill tubes with creams, gels, or liquids. Cartoning machines similarly use pneumatics to transfer filled products into cartons. Bundling machines wrap groups of cartons in film using cylinders for cutting, heating, and collating. Pneumatic components are critical for automating pharmaceutical packaging operations at high speeds.