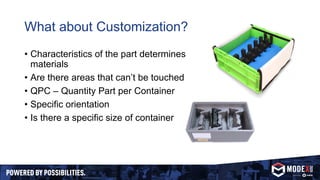

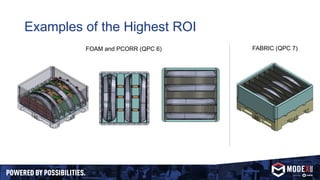

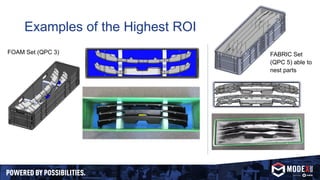

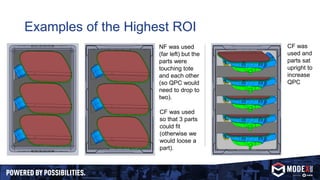

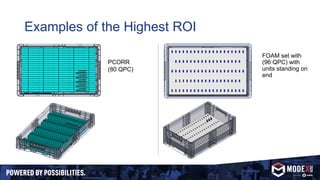

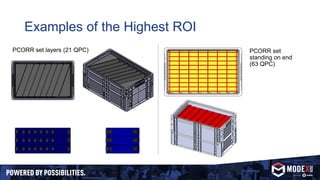

The document discusses optimizing returnable packaging programs by focusing on total cost, highlighting the benefits of returnables across various industries such as automotive, food, and pharmaceuticals. It details trends in reusable packaging, cost savings, and the importance of customization and efficient transportation within the supply chain. The presentation also provides examples of returnable packaging configurations that yield a high return on investment.