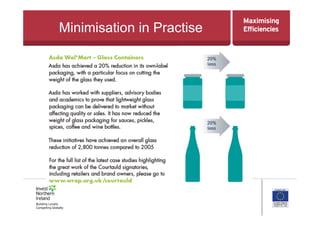

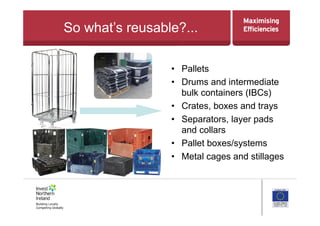

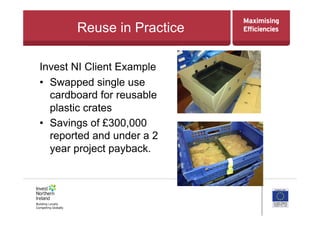

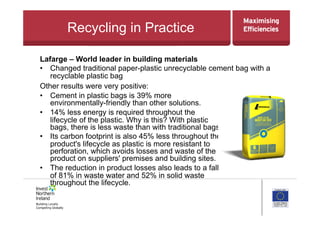

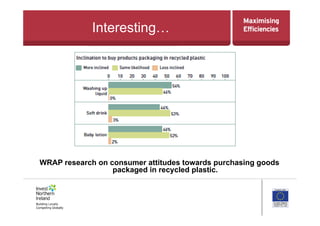

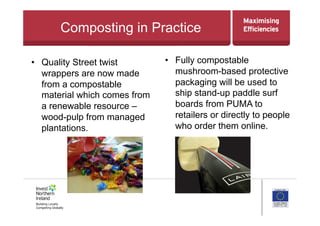

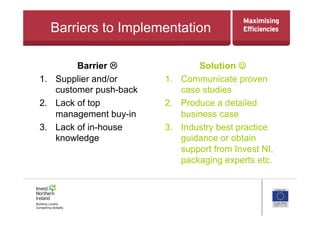

The document summarizes a workshop on packaging sustainability. The agenda covers how packaging impacts businesses and the environment, eco-design principles like minimization, reuse, recycling and composting, and barriers to implementing more sustainable packaging. Examples are given of companies optimizing packaging to reduce costs through less material usage. Opportunities discussed for attendees' businesses include minimizing packaging size and weight, reusing incoming supplier packaging, and choosing materials that can be recycled or composted.