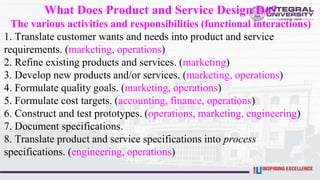

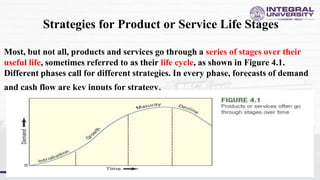

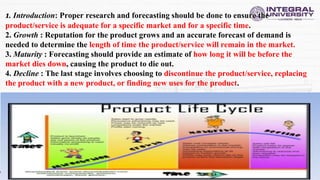

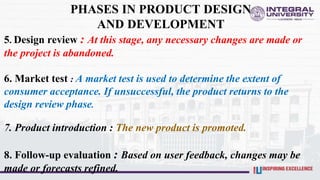

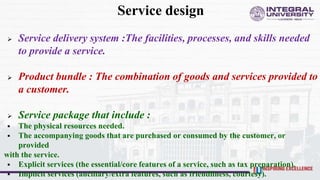

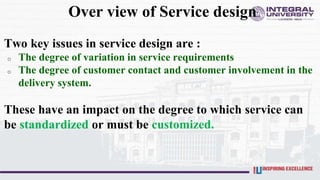

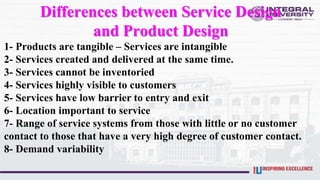

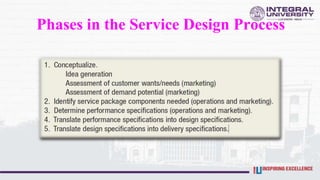

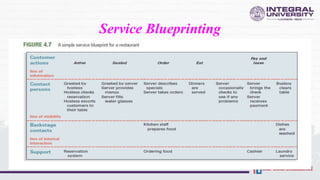

The document discusses the strategic importance of product and service design in operations management, highlighting factors that influence design strategies such as cost, quality, and customer satisfaction. It emphasizes the collaborative nature of the design process, the impact of market opportunities and challenges, and the need to consider environmental and ethical factors. Additionally, it outlines phases in service design, including service blueprinting and the differences between product and service design.