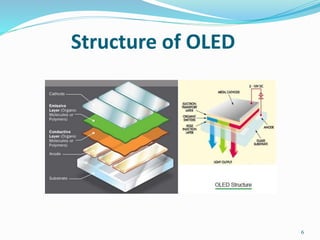

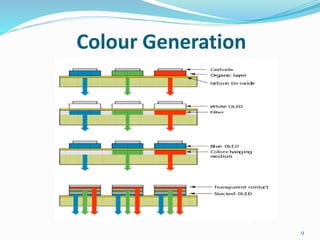

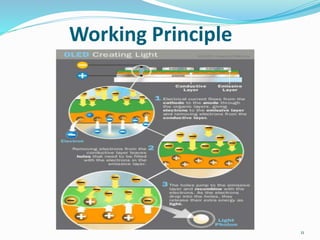

This document summarizes a seminar presentation on organic light-emitting diodes (OLEDs). It discusses the history and development of OLEDs from their invention in 1987. The key features of OLEDs are described, including their flexibility, emissive technology, light weight, thinness, and low power consumption. The document outlines the structure, fabrication, deposition methods, working principle, types, advantages, and applications of OLEDs. It concludes that OLED display technology has the potential to improve upon limitations of LCD such as high power consumption and limited viewing angles.