The document provides an overview of ORNL's automotive research capabilities across several areas:

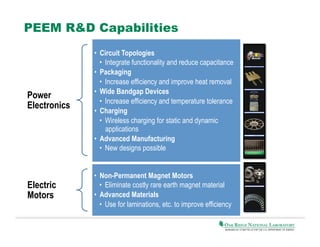

1) It describes ORNL's research programs in electrification, efficient vehicles, alternative fuels, intelligent systems and new transportation technologies and processes.

2) Several key facilities are highlighted including a power electronics lab, vehicle systems integration lab, battery manufacturing facility, and manufacturing demonstration facility.

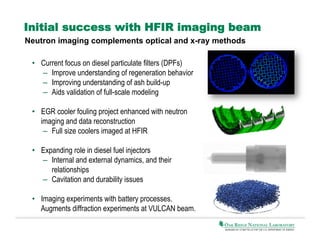

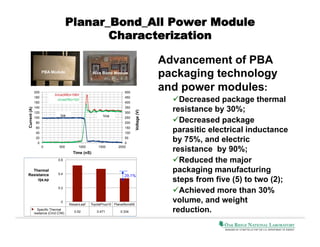

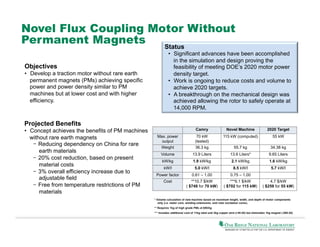

3) Specific projects involving neutron imaging of diesel particulate filters, high performance computing simulations, and development of a planar bond all power module and flux coupling motor without permanent magnets are summarized.