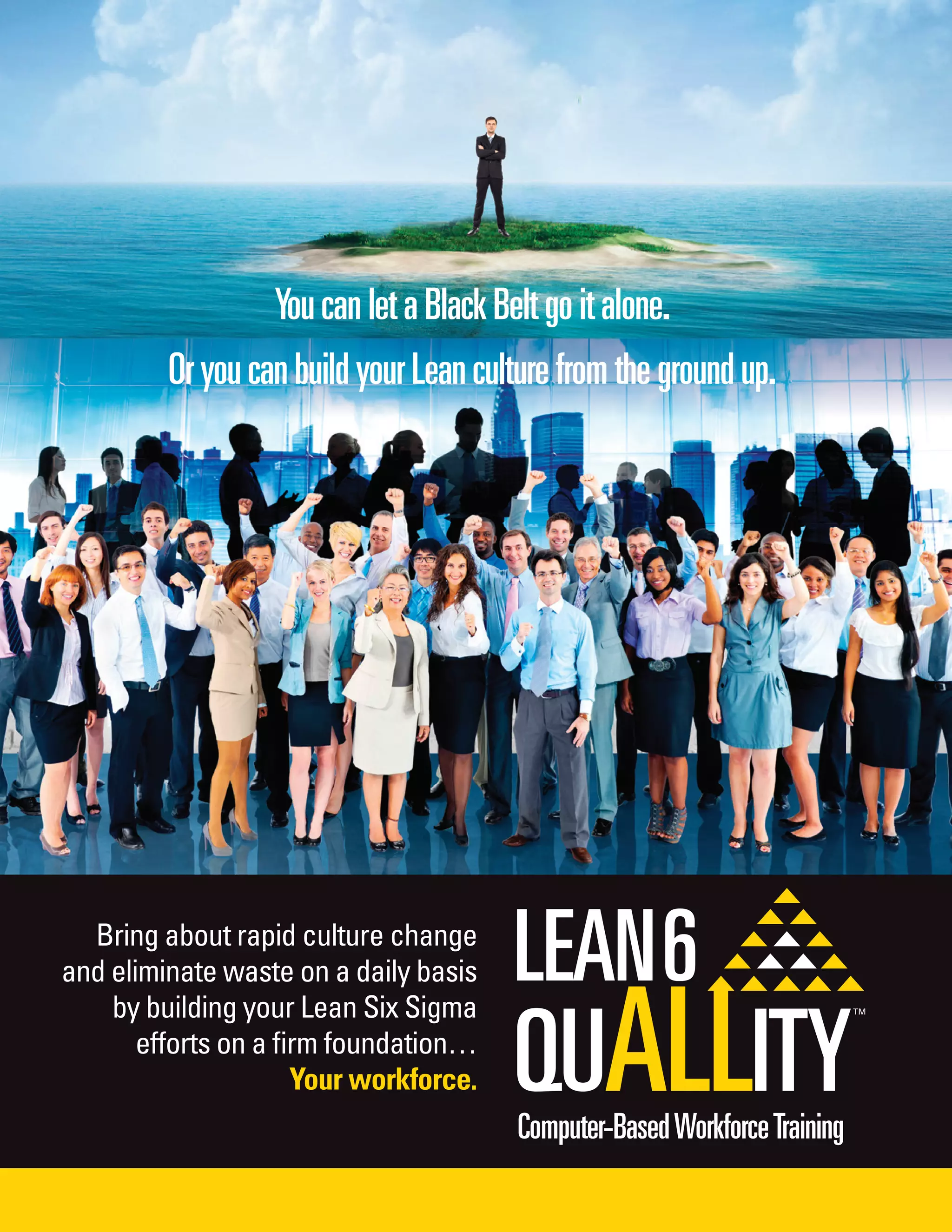

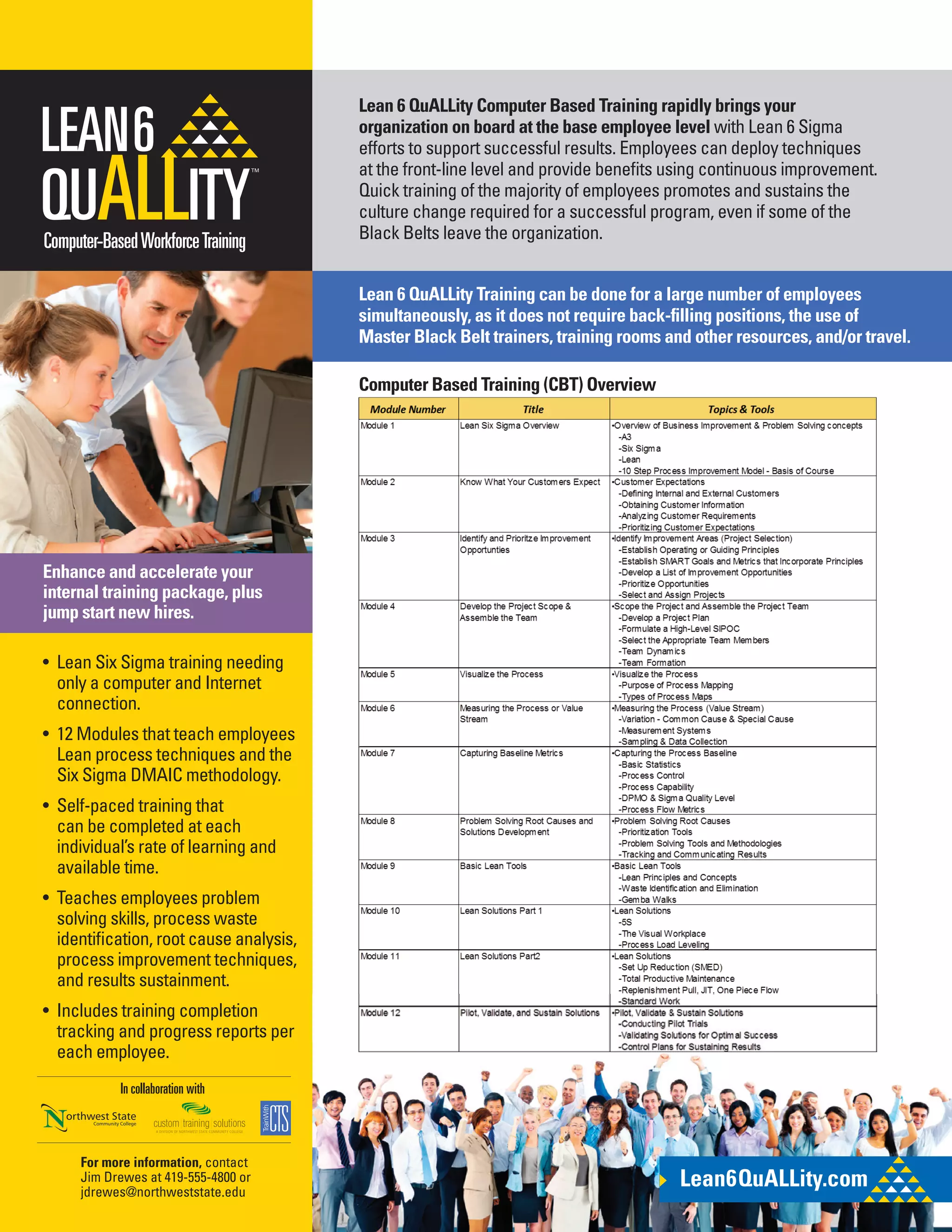

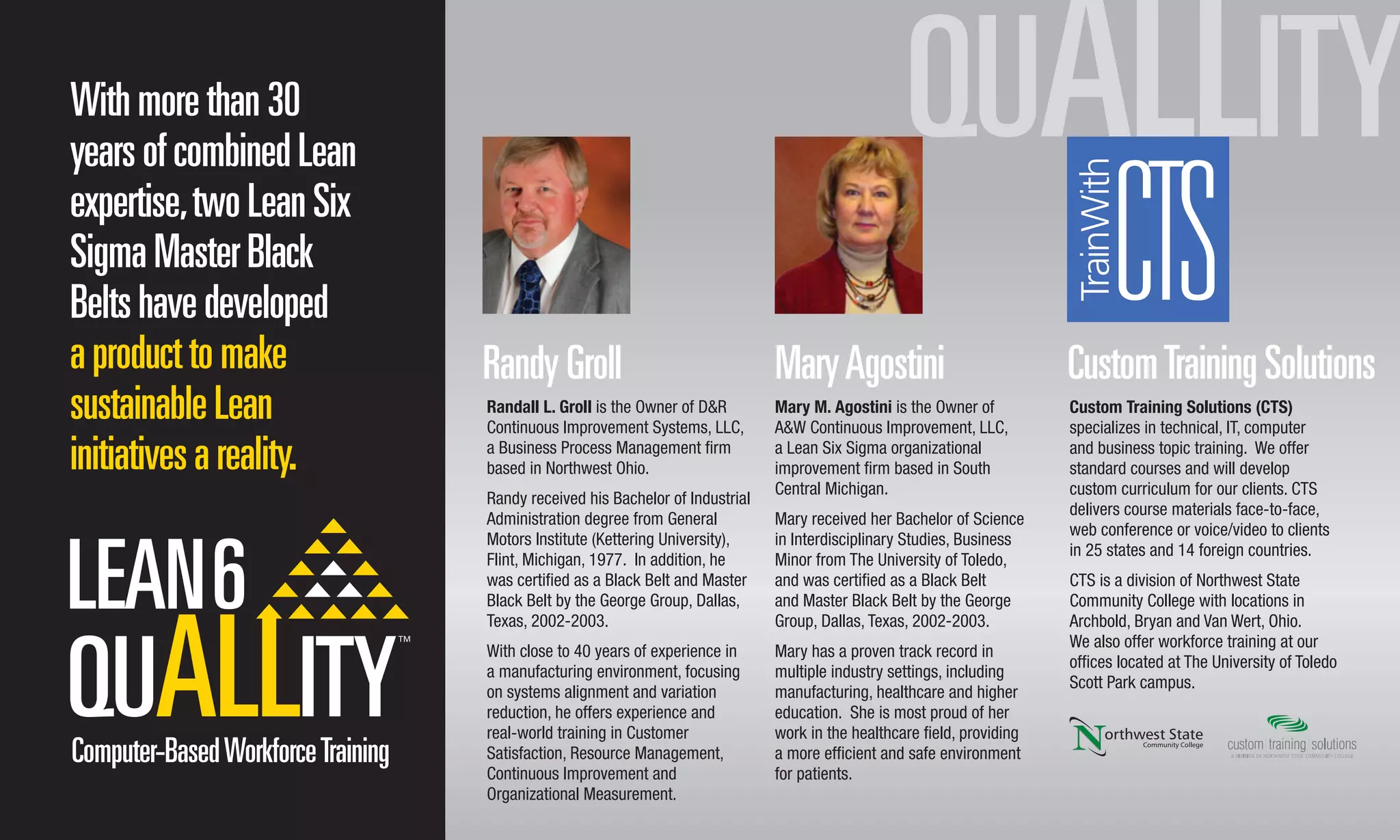

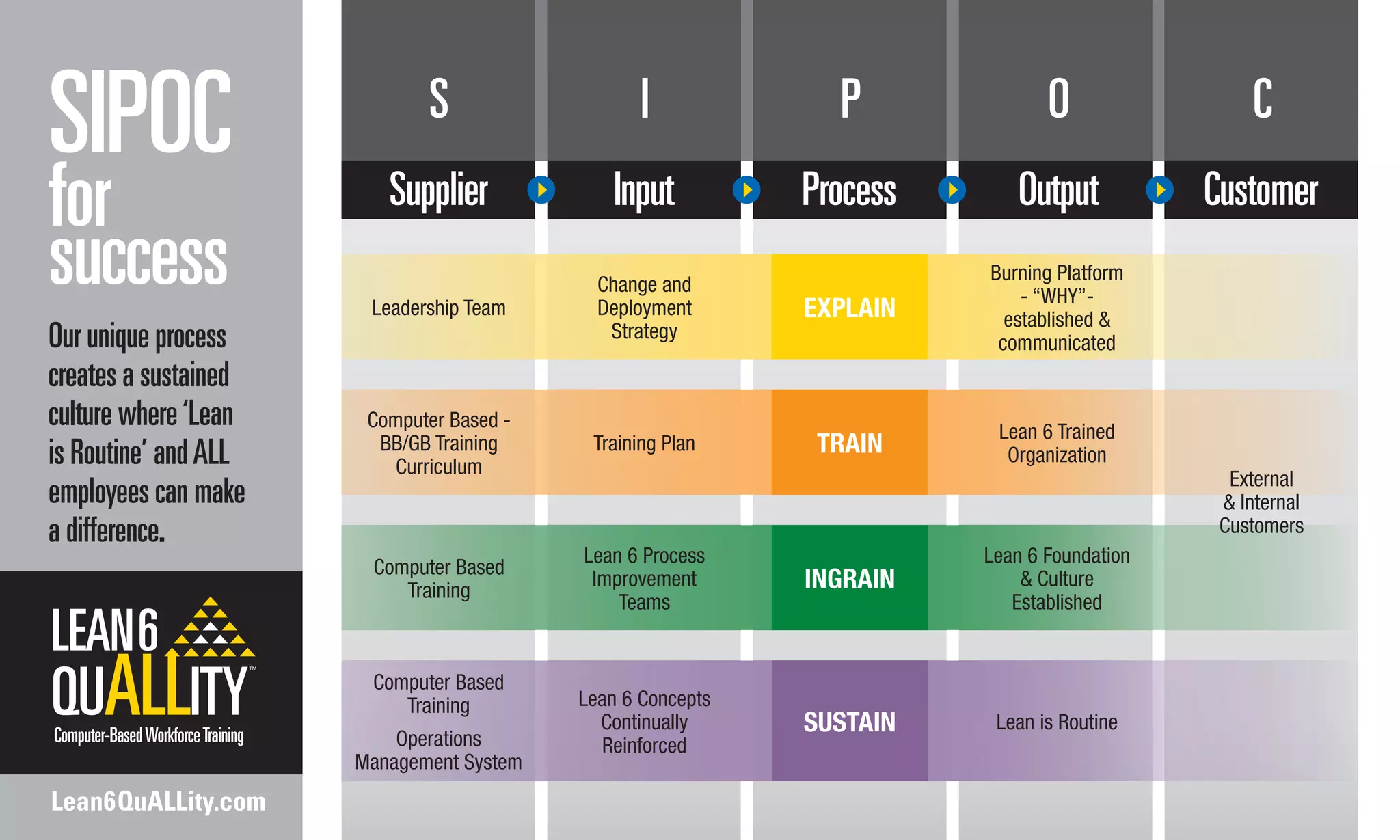

The document outlines a computer-based workforce training program designed to instill lean six sigma methodologies in organizations. It offers self-paced, 12-module training that enhances employee skills in process improvement, waste elimination, and problem-solving, and is suitable for large teams without resource constraints. The program aims to create a sustainable culture where lean practices become routine for all employees, ultimately improving efficiency in both manufacturing and healthcare environments.