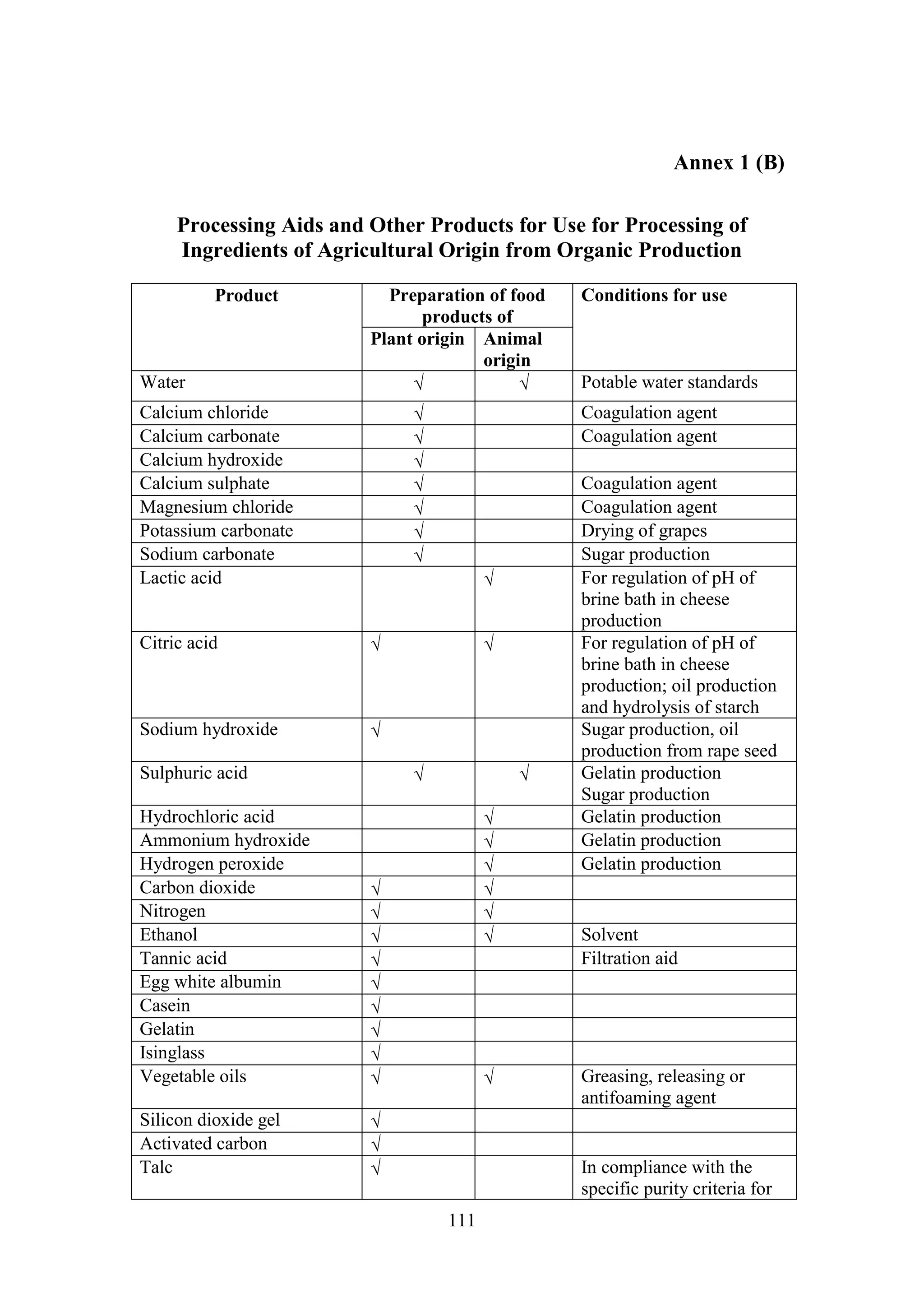

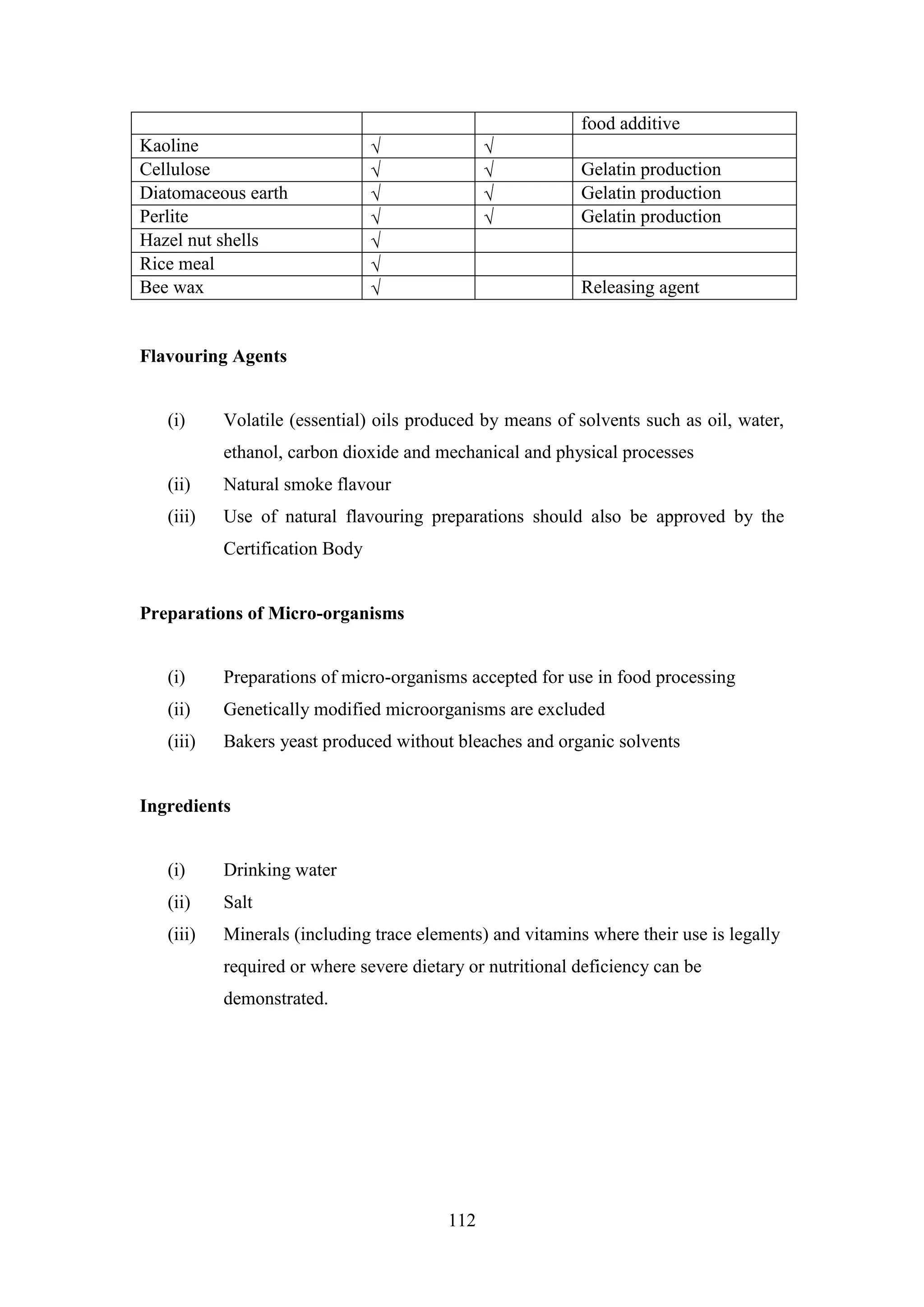

This document outlines requirements for organic food processing and handling. It discusses the organic production and handling plan, pest control methods, ingredients, processing methods, packaging, labeling, and storage/transport. Specific requirements include developing a processing plan, using approved ingredients and additives, preventing commingling of organic and non-organic products, approved physical/mechanical processing methods, using biodegradable packaging, and clearly labeling organic products. Pest control focuses on prevention over treatment, and only approved substances are permitted.