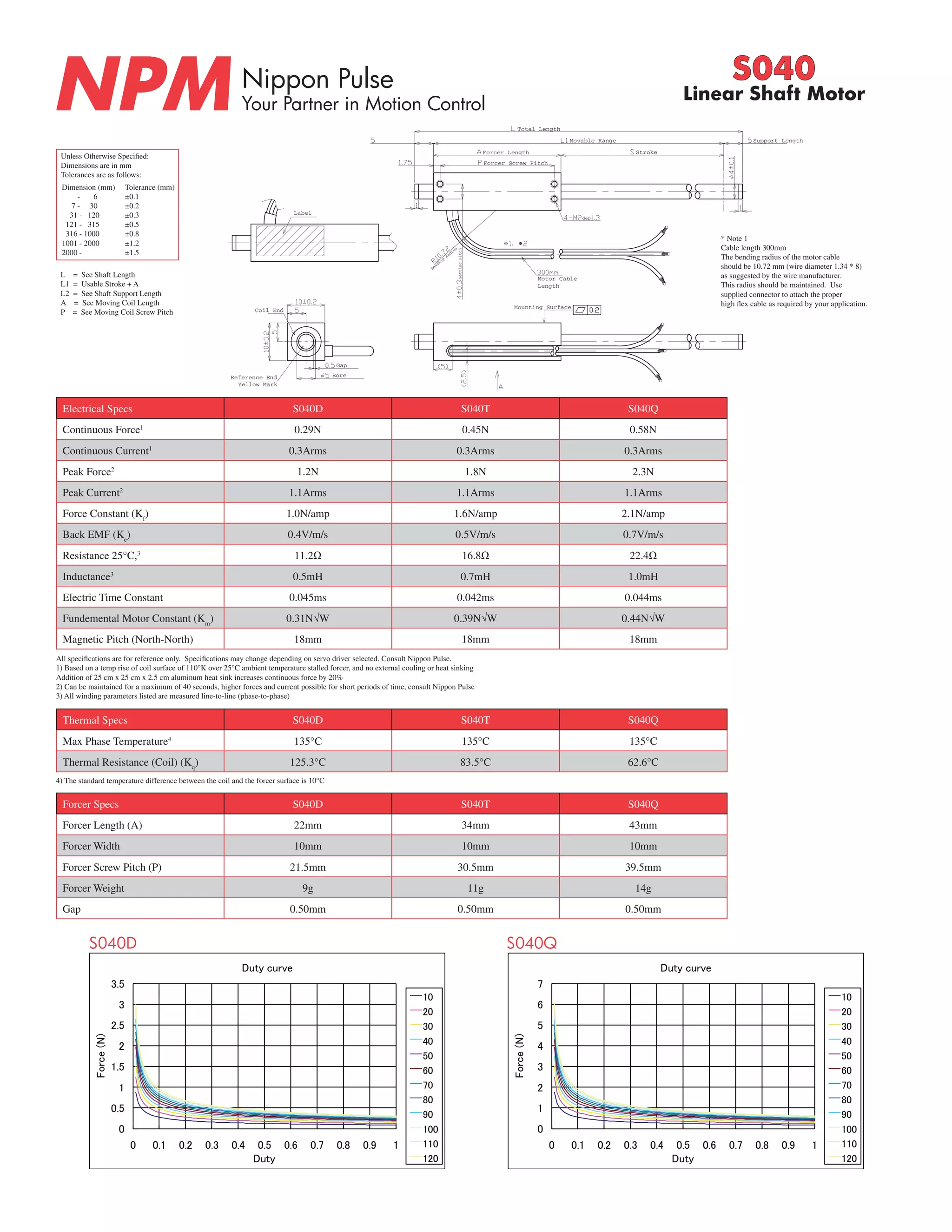

The document provides specifications for Nippon Pulse linear shaft motors models S040D, S040T, and S040Q. It includes details on dimensions, electrical specifications like force, current and resistance, thermal specifications, force specifications, duty curves, shaft lengths, masses, lead wire and connector information. Tolerances for dimensions are provided in a table.