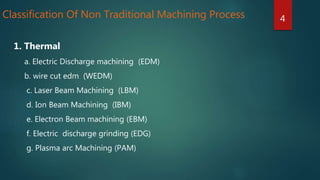

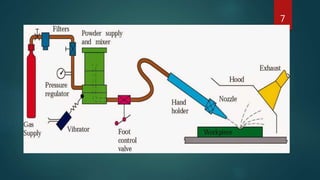

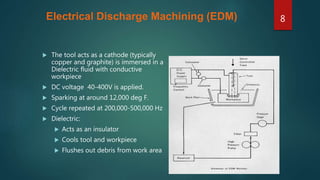

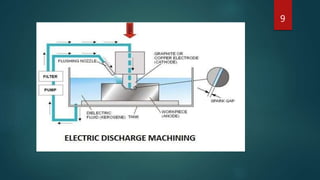

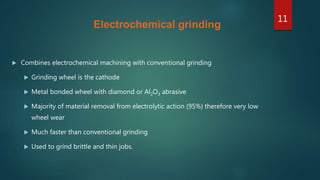

Non-traditional machining processes such as EDM, ECM, laser beam machining and abrasive jet machining remove material using thermal energy, electrochemical reactions, or abrasive particles rather than mechanically. They allow machining of hard, brittle, or heat-sensitive materials. Key advantages over traditional machining are higher accuracy due to lack of tool wear, finer surface finishes, and ability to machine complex shapes. However, non-traditional machining can be more expensive and require more complex setups and skilled operators.