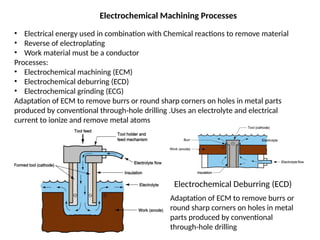

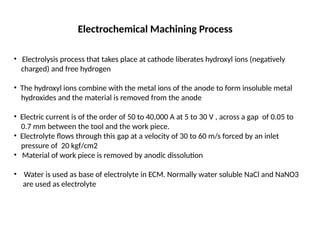

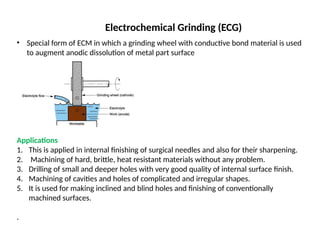

Non-traditional machining processes are essential for shaping difficult-to-machine advanced materials such as high-strength alloys and composites, which cannot be effectively processed using conventional methods. These advanced techniques encompass mechanical, electrochemical, electro-thermal, and chemical processes, each offering unique advantages and limitations for precision machining. Applications range from aerospace components to intricate designs in medical instrumentation, and while they provide benefits like reduced surface damage and high accuracy, they often require significant capital investment and skilled operators.