This document discusses different molding techniques for rubber compounds:

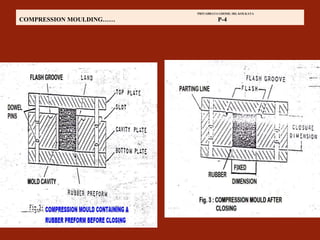

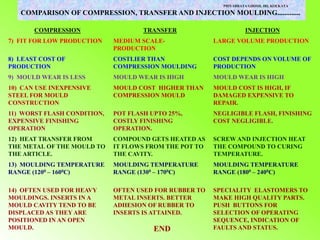

- Compression molding involves placing rubber in a heated mold cavity and applying pressure. Flash and semi-positive molds are discussed.

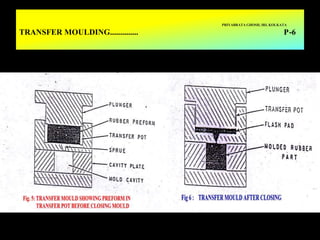

- Transfer molding uses pre-heated rubber that is forced through holes into mold cavities. It allows for more complex shapes than compression molding.

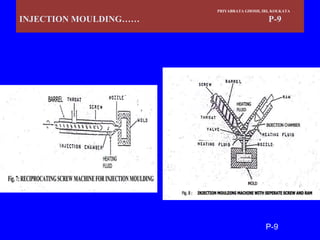

- Injection molding automatically feeds, heats, and injects rubber into a closed, heated mold. It produces consistent, high-quality parts at high speeds but requires specialized rubber compounds.