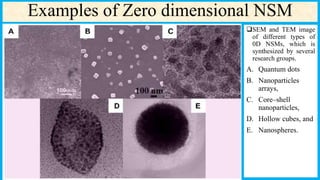

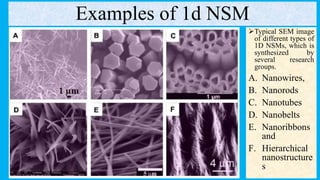

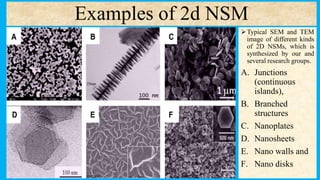

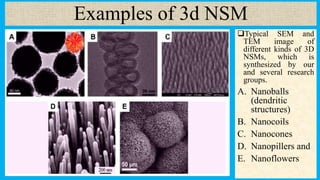

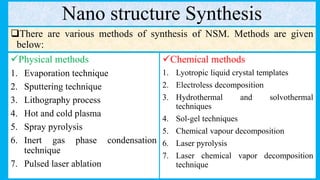

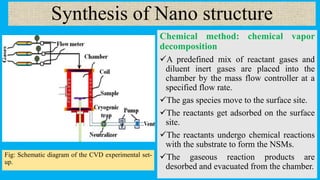

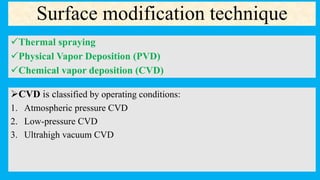

This document discusses nanostructures, their synthesis, and surface modification techniques. It defines nanostructures as having at least one dimension between 1-100 nm. Nanostructures are classified based on dimensionality as 0D, 1D, 2D, and 3D. Common synthesis methods include physical vapor deposition, chemical vapor deposition, and thermal spraying. Surface modification is done to change properties like reactivity, roughness, and corrosion protection. Common modification techniques are thermal spraying, PVD, and CVD.