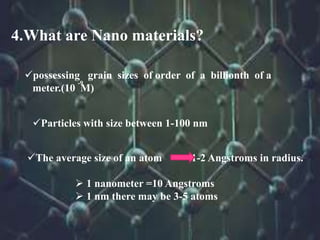

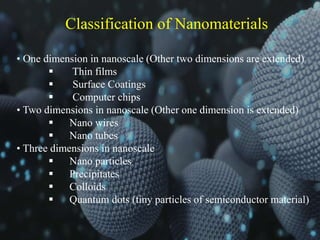

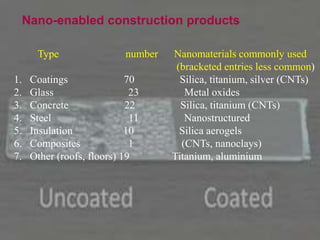

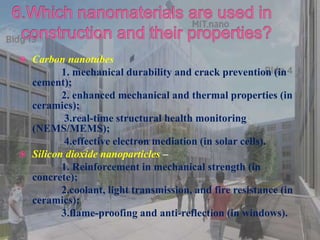

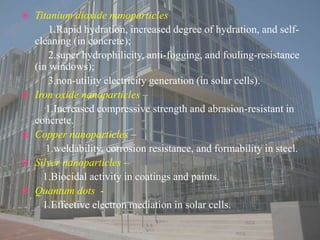

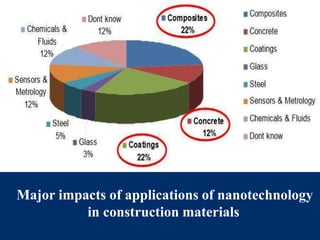

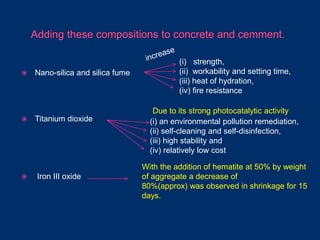

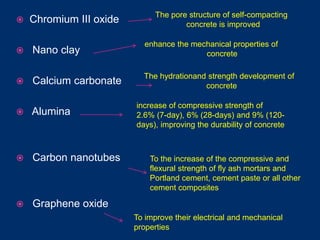

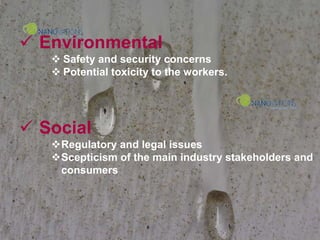

This document discusses nano materials and their applications in construction. It begins by defining nanotechnology and nanomaterials as materials that have dimensions measured in nanometers. It then classifies nanomaterials and discusses some that are commonly used in construction like carbon nanotubes, silicon dioxide nanoparticles, titanium dioxide nanoparticles, and iron oxide nanoparticles. The document outlines benefits of nanomaterials like increased strength, durability, and sustainability. It also discusses barriers to adoption like costs, environmental concerns, and regulatory issues. In summary, the document provides an overview of nano materials, their properties and applications in construction, as well as benefits and challenges to their increased use.