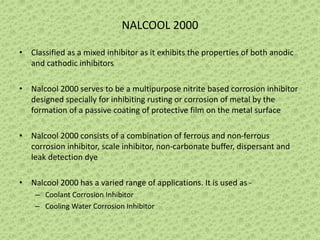

Nalcool 2000 is a widely used corrosion inhibitor produced by Chemtex Specialty Limited, designed to prevent rust and corrosion in various applications. It functions as a mixed inhibitor, offering multi-metal protection and scale prevention while enhancing system efficiency and life. Nalcool 2000 is effective in automotive and cooling tower applications, addressing corrosion through the formation of a protective film on metal surfaces.