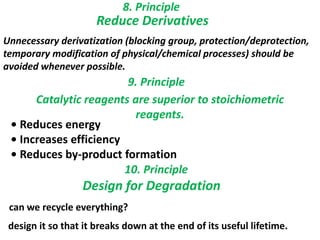

The document outlines 12 principles of green chemistry, beginning with a brief history of environmental protection efforts leading to the development of green chemistry. It then details each of the 12 principles, which focus on preventing waste, maximizing atom economy in chemical processes, designing safer chemicals and chemical processes, encouraging renewable resources and energy efficiency, and enabling chemical reactions and processes to be less hazardous. The principles provide a framework for chemists to consider the environmental impacts of their work.