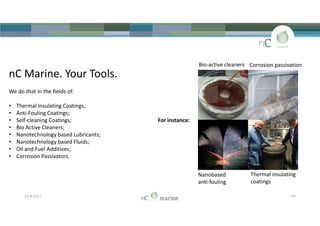

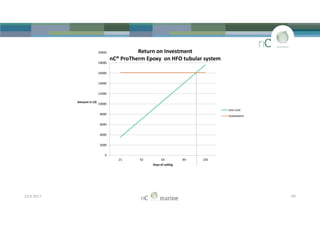

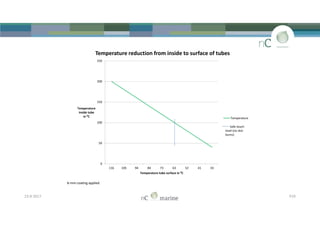

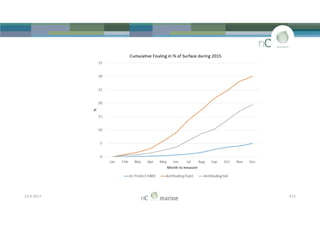

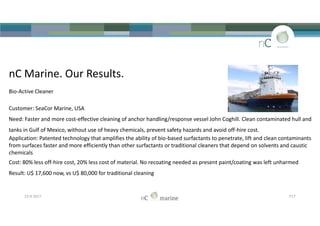

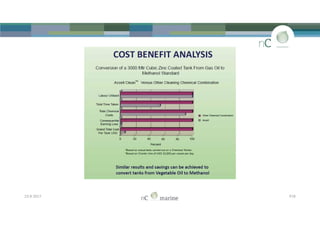

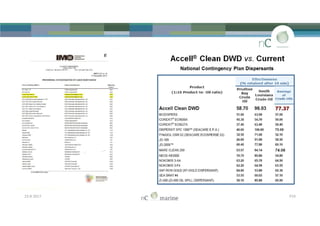

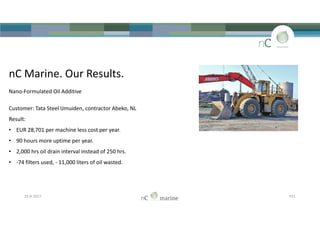

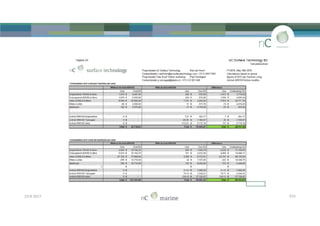

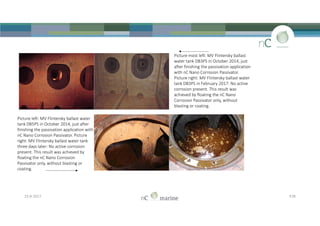

The document provides examples of results from using various products and services from nC Group of Companies to improve reliability, safety, and reduce costs for assets like ships, plants, engines, and equipment. Some key results highlighted include reducing fuel costs for heating pipelines using thermal insulating coatings with a return on investment of 95 days, protecting ship hulls from fouling for over a year using nano-based anti-fouling coatings at a lower cost than traditional coatings, and avoiding an expected $23,000 repair project by adding a nano-based thermal fluid system conditioner for $5,900. The document aims to convince readers that nC Group can be a sensible partner through demonstrated cost savings and performance improvements.