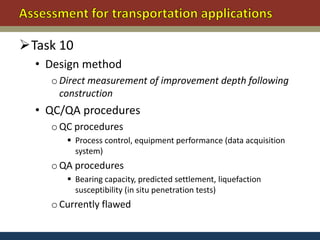

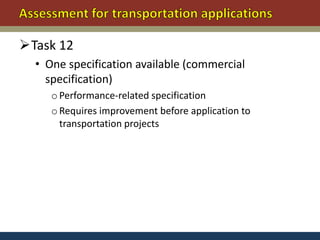

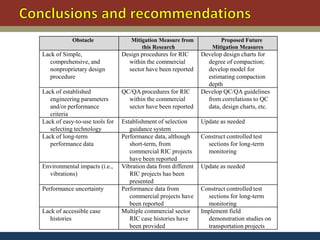

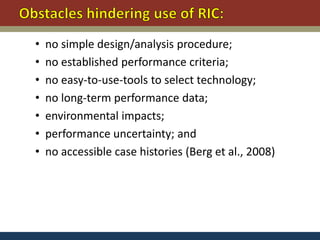

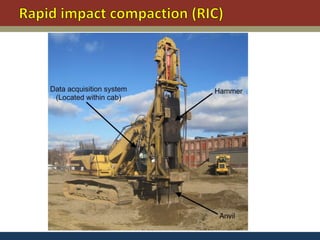

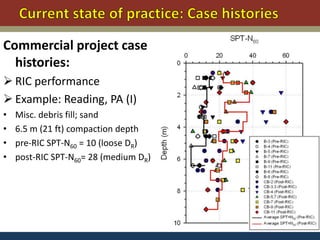

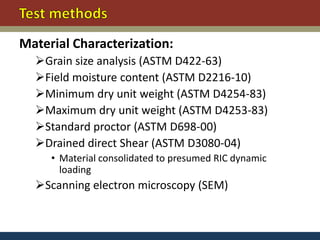

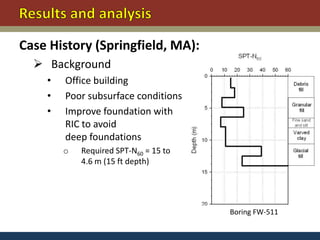

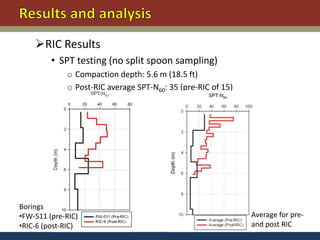

This thesis defense evaluates the potential of Rapid Impact Compaction (RIC) for transportation infrastructure projects, highlighting obstacles to its adoption such as lack of established design procedures and long-term performance data. The research objectives include expanding the knowledge base and assessing applicability of RIC in civil engineering, supported by detailed case histories. Recommendations for overcoming barriers to implementation and improving QC/QA procedures are also presented.

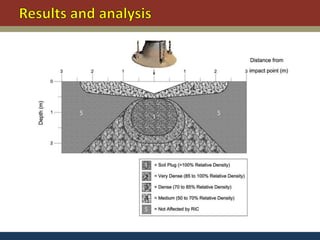

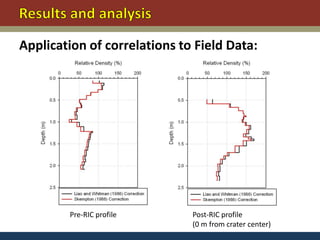

![Spatially analyzed relative density profile

[Liao and Whitman (1986) correction]:](https://image.slidesharecdn.com/defensepresentation-13356233706208-phpapp02-120428093259-phpapp02/85/M-S-Thesis-Defense-26-320.jpg)