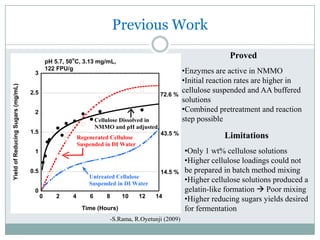

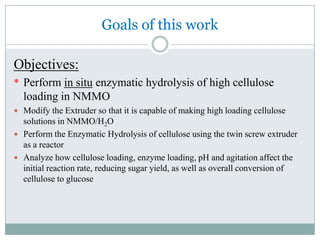

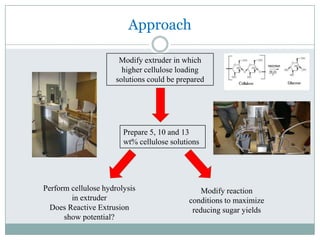

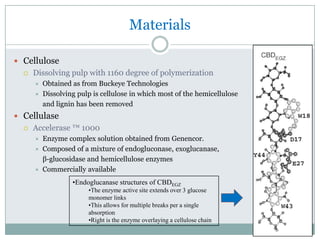

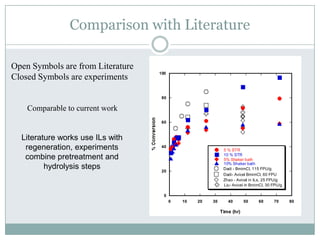

The document summarizes research on enzymatic hydrolysis of cellulose in the ionic liquid NMMO. Key findings include:

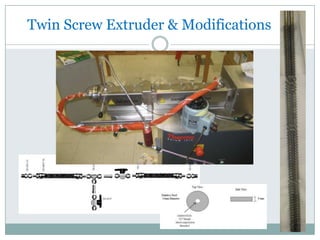

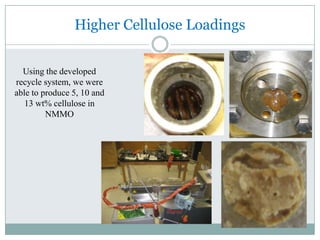

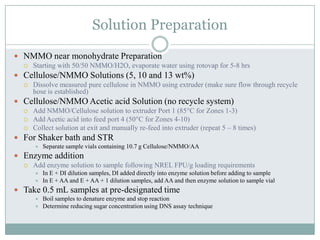

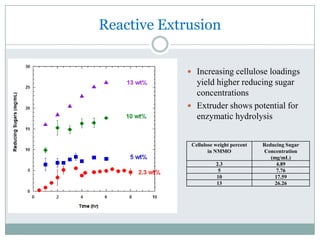

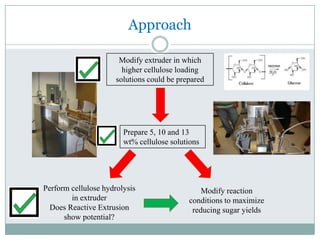

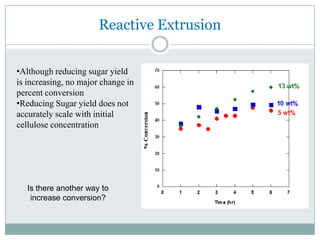

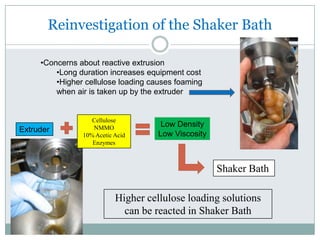

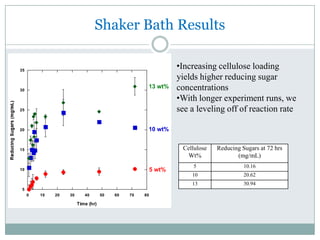

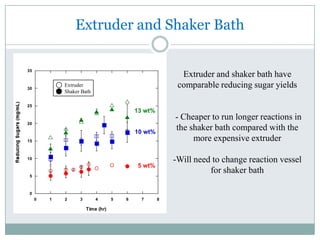

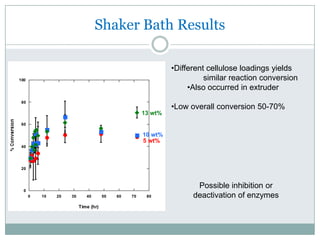

1) A twin screw extruder was modified to produce high cellulose loading solutions of up to 13% in NMMO/H2O. Enzymatic hydrolysis reactions were then performed in the extruder.

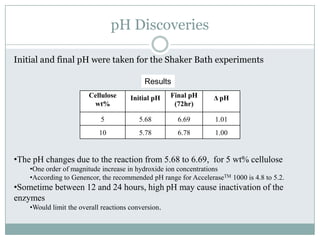

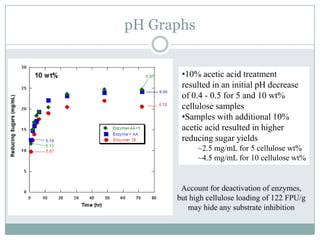

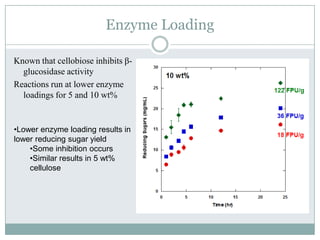

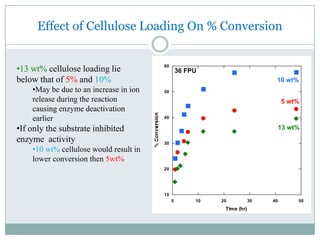

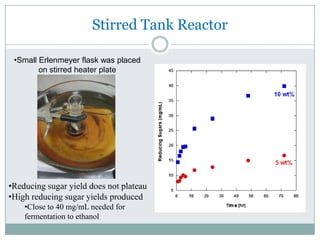

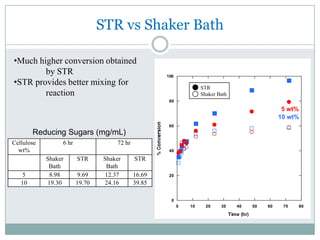

2) Reaction conditions like cellulose loading, enzyme loading, pH, and agitation method significantly impacted sugar yields and conversion rates. The highest yield was obtained at 10% cellulose, 122 FPU/g enzymes, and acidic pH in a stirred tank reactor.

3) A stirred tank reactor provided better mixing than a shaker bath and achieved near complete conversion of cell