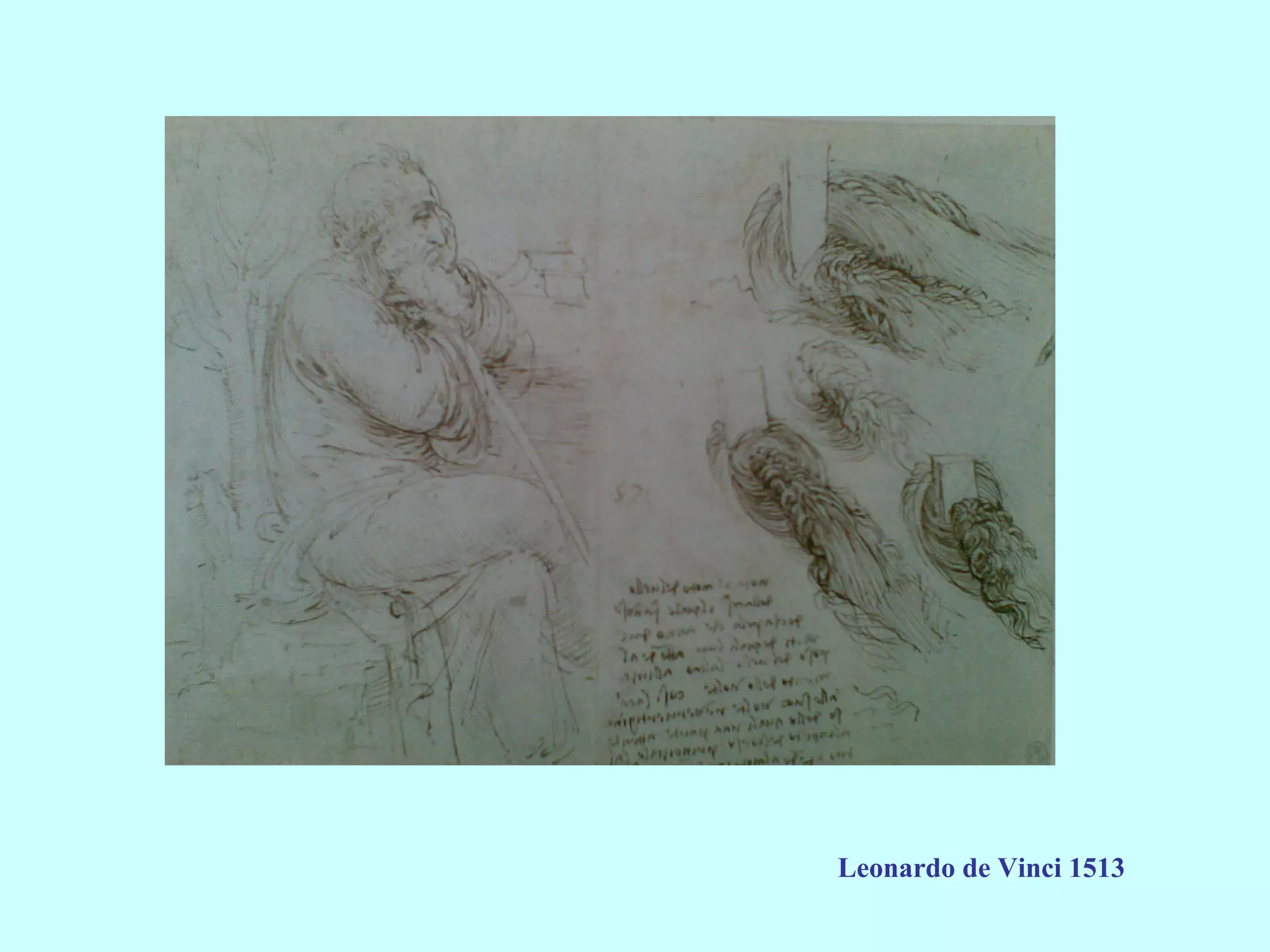

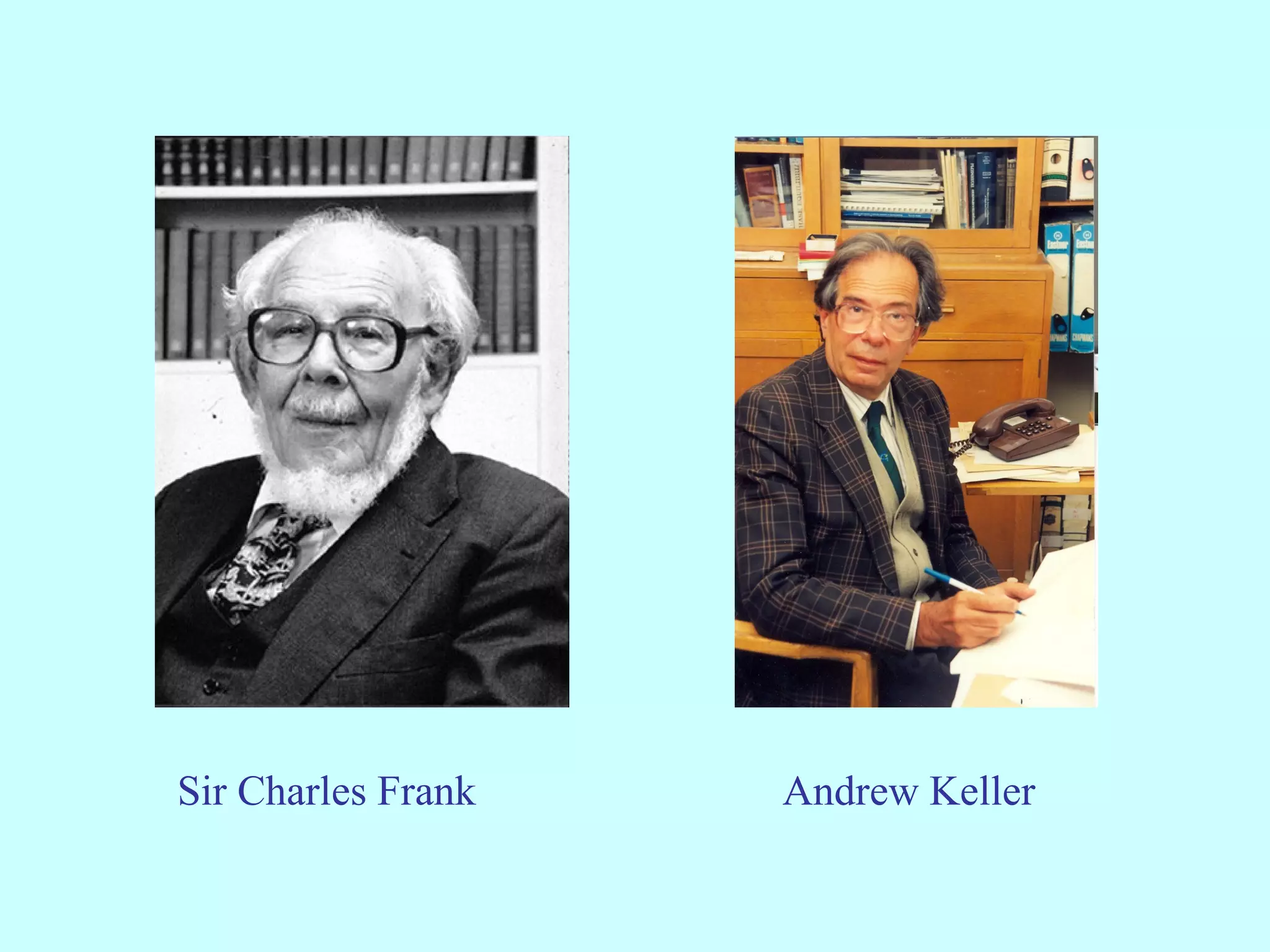

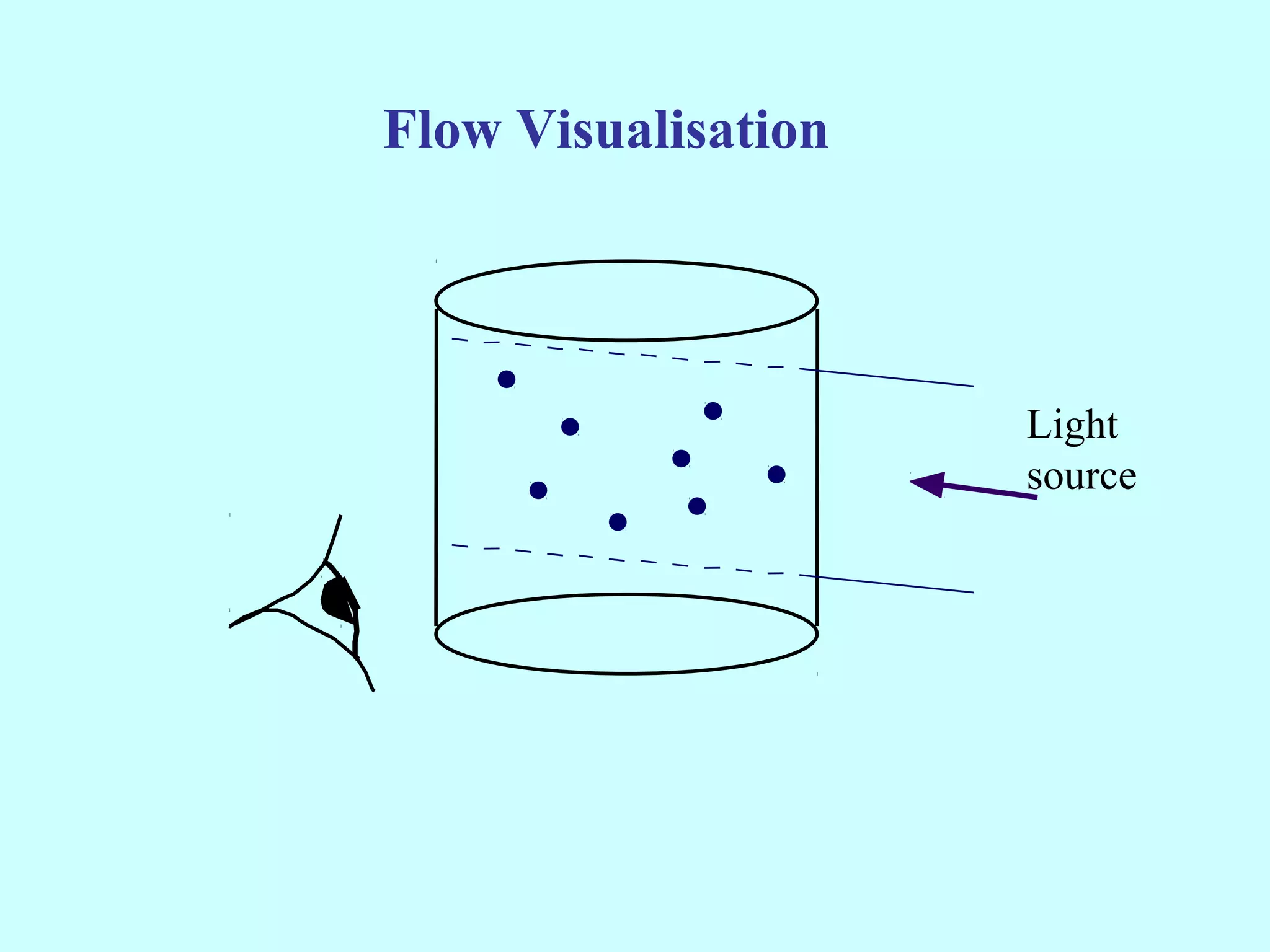

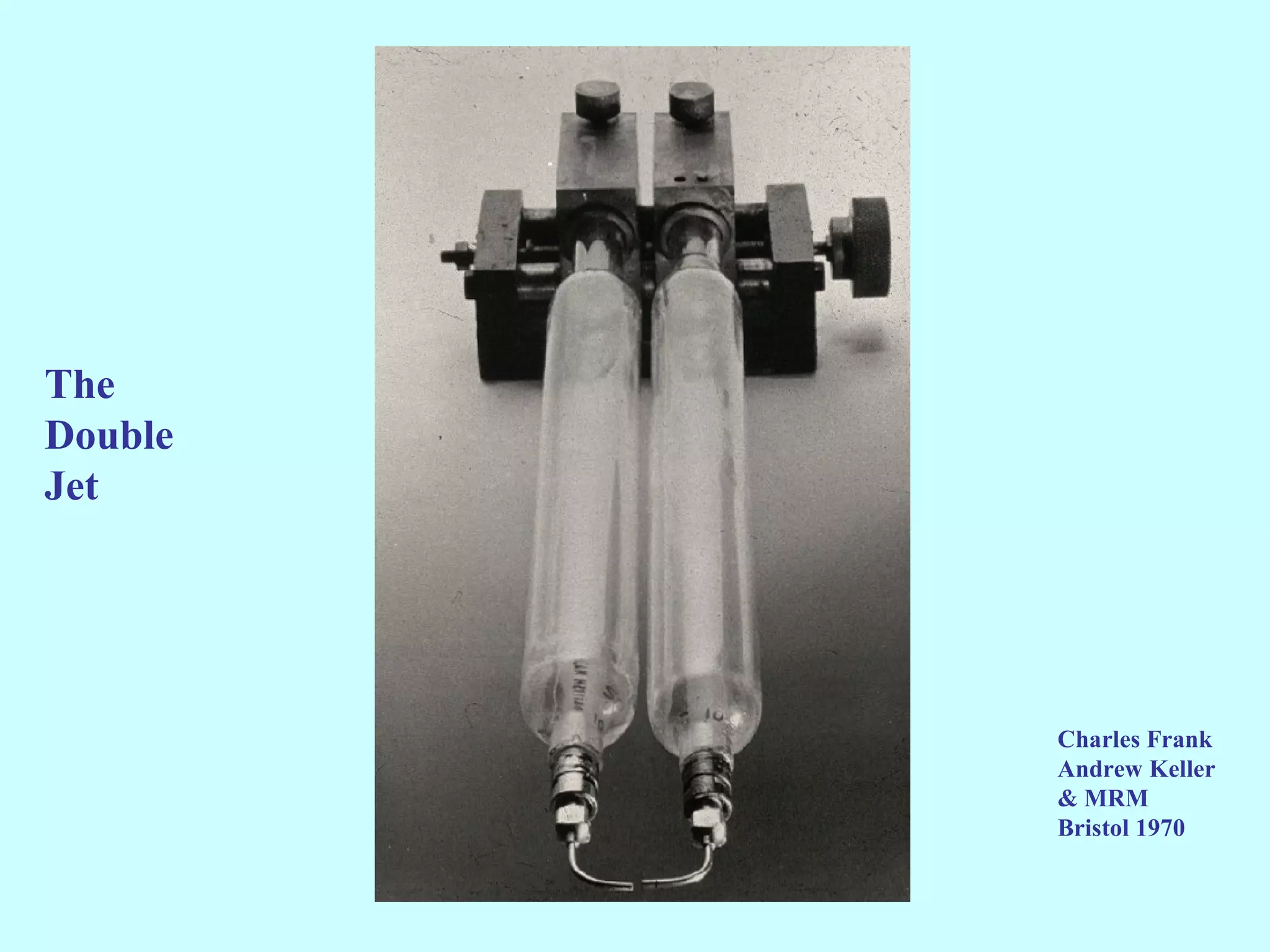

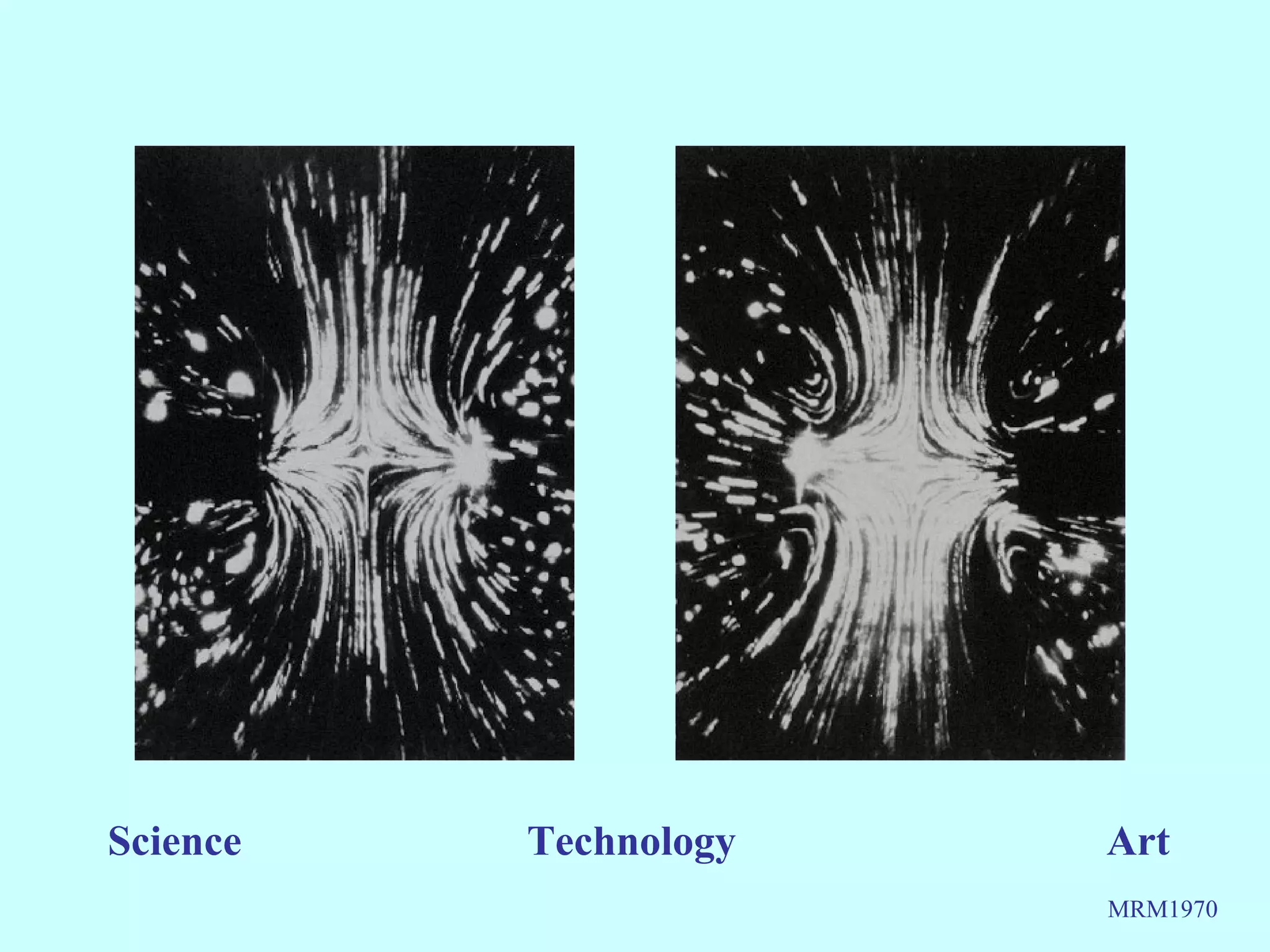

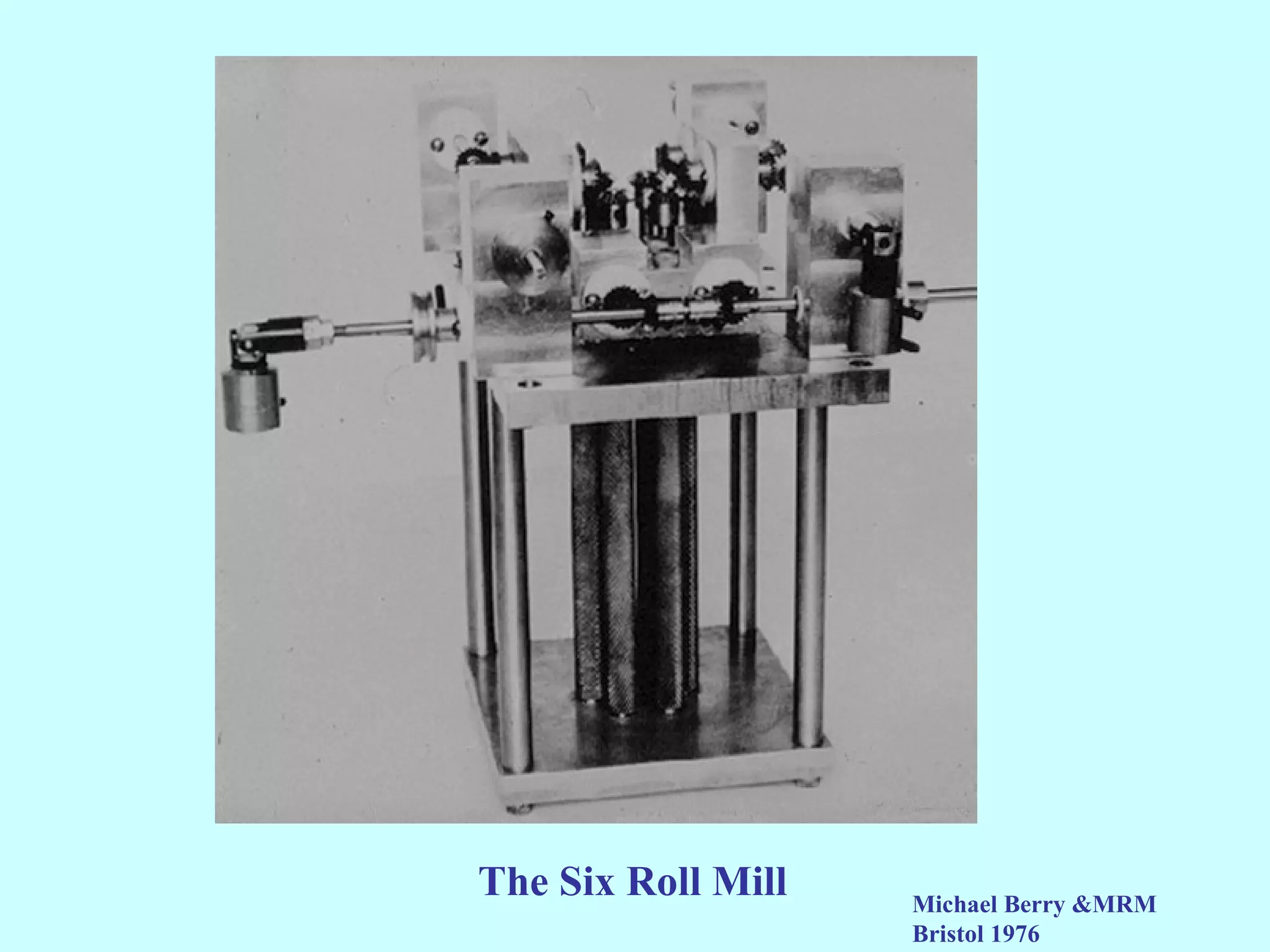

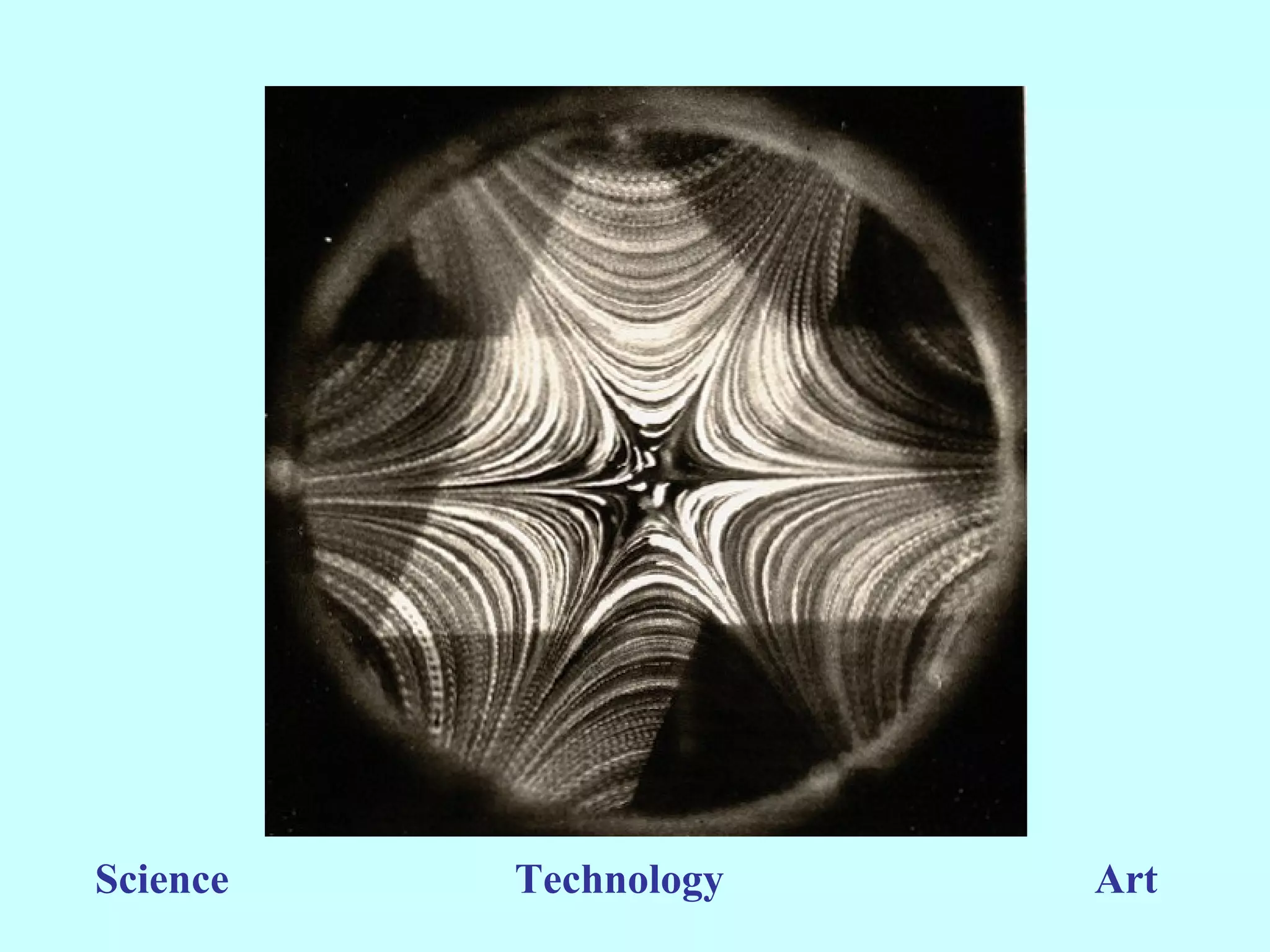

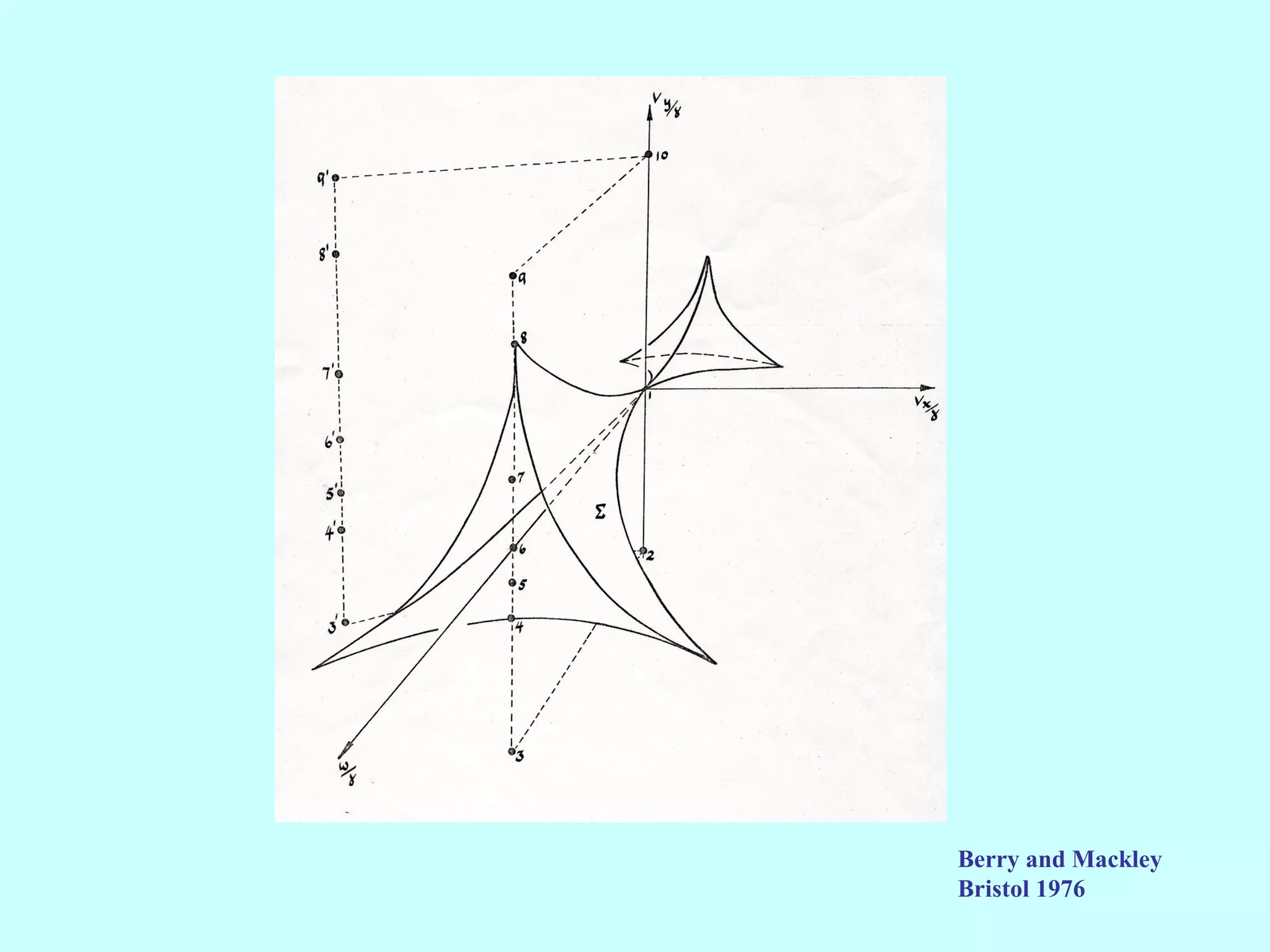

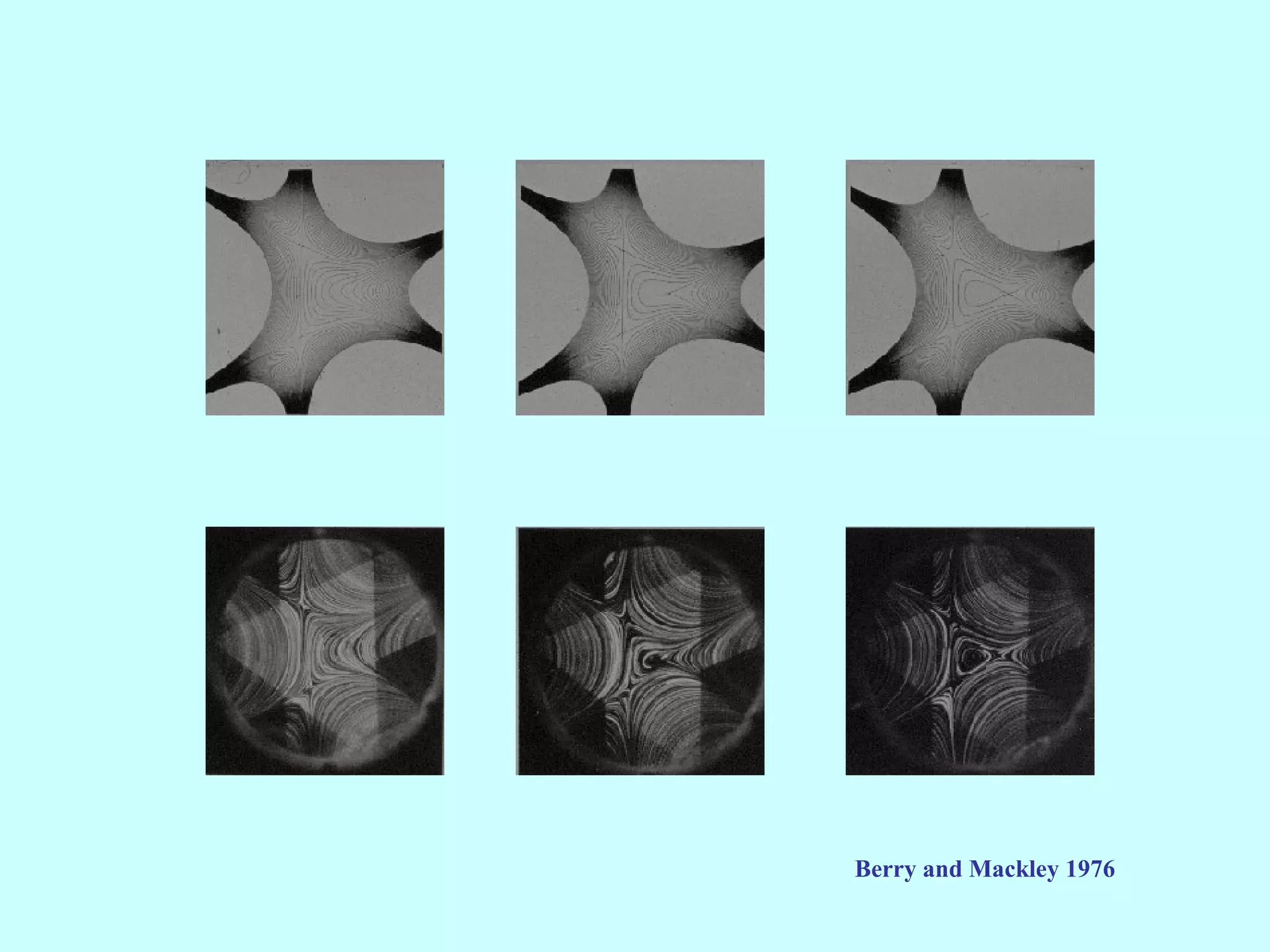

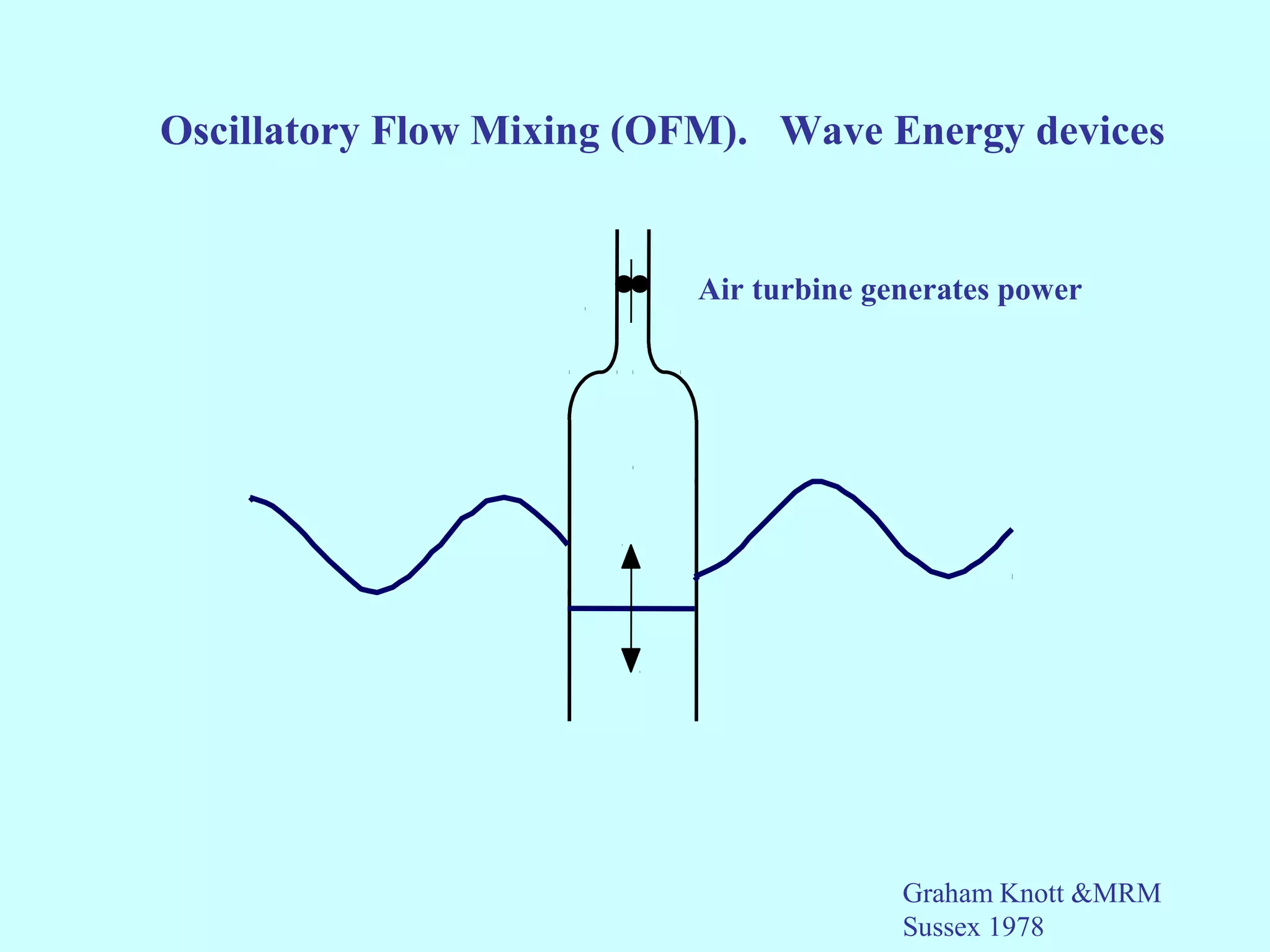

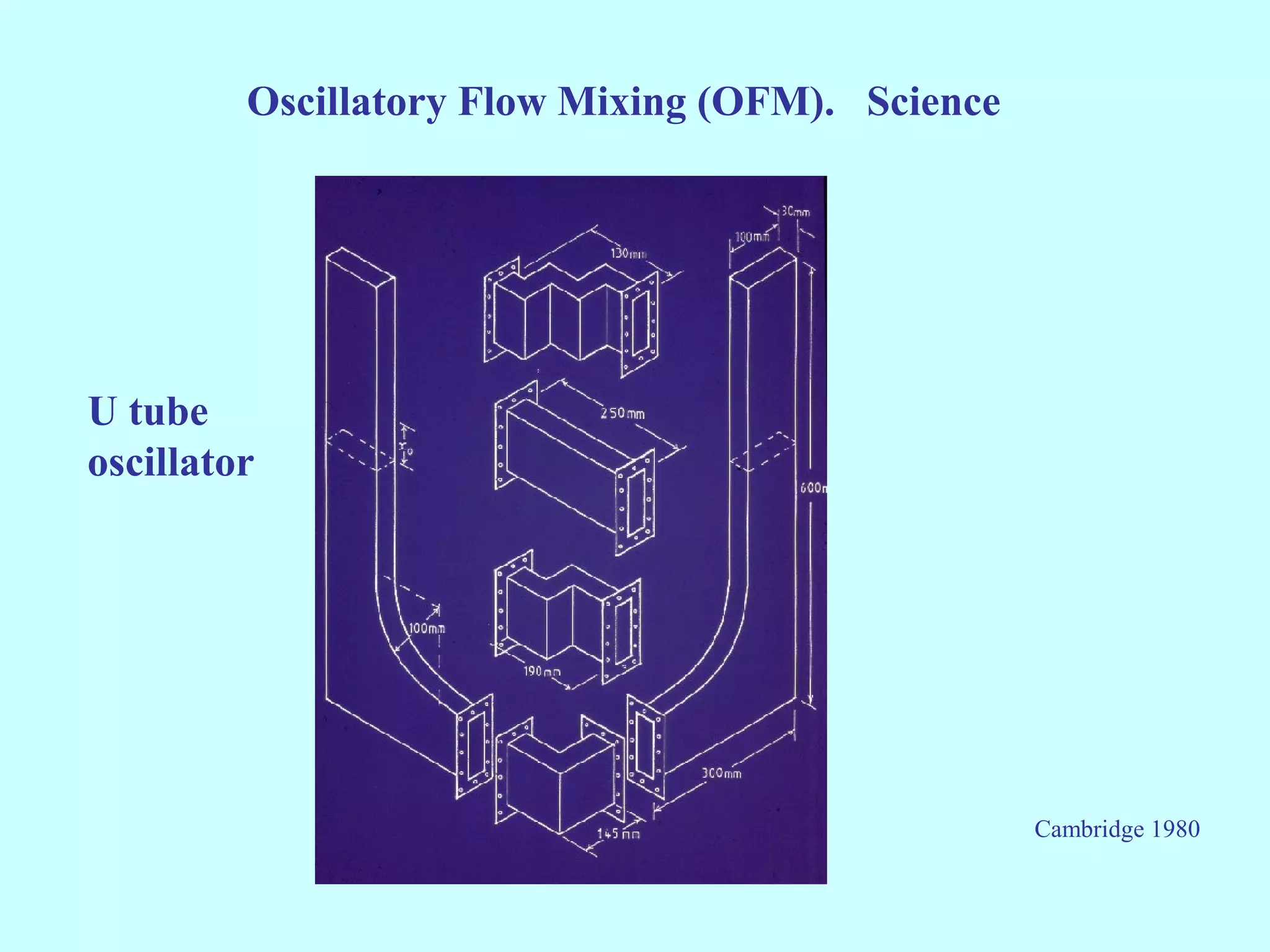

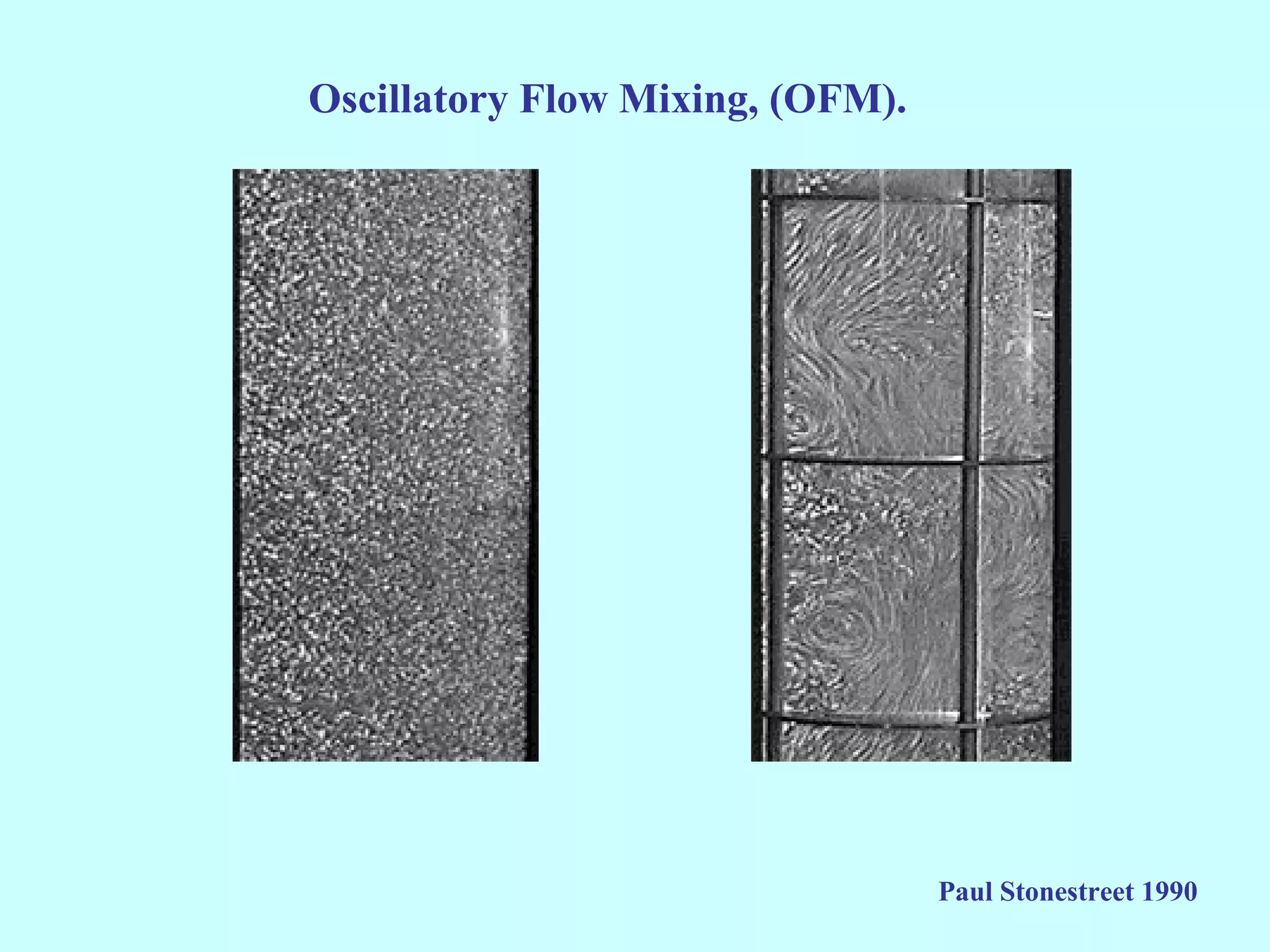

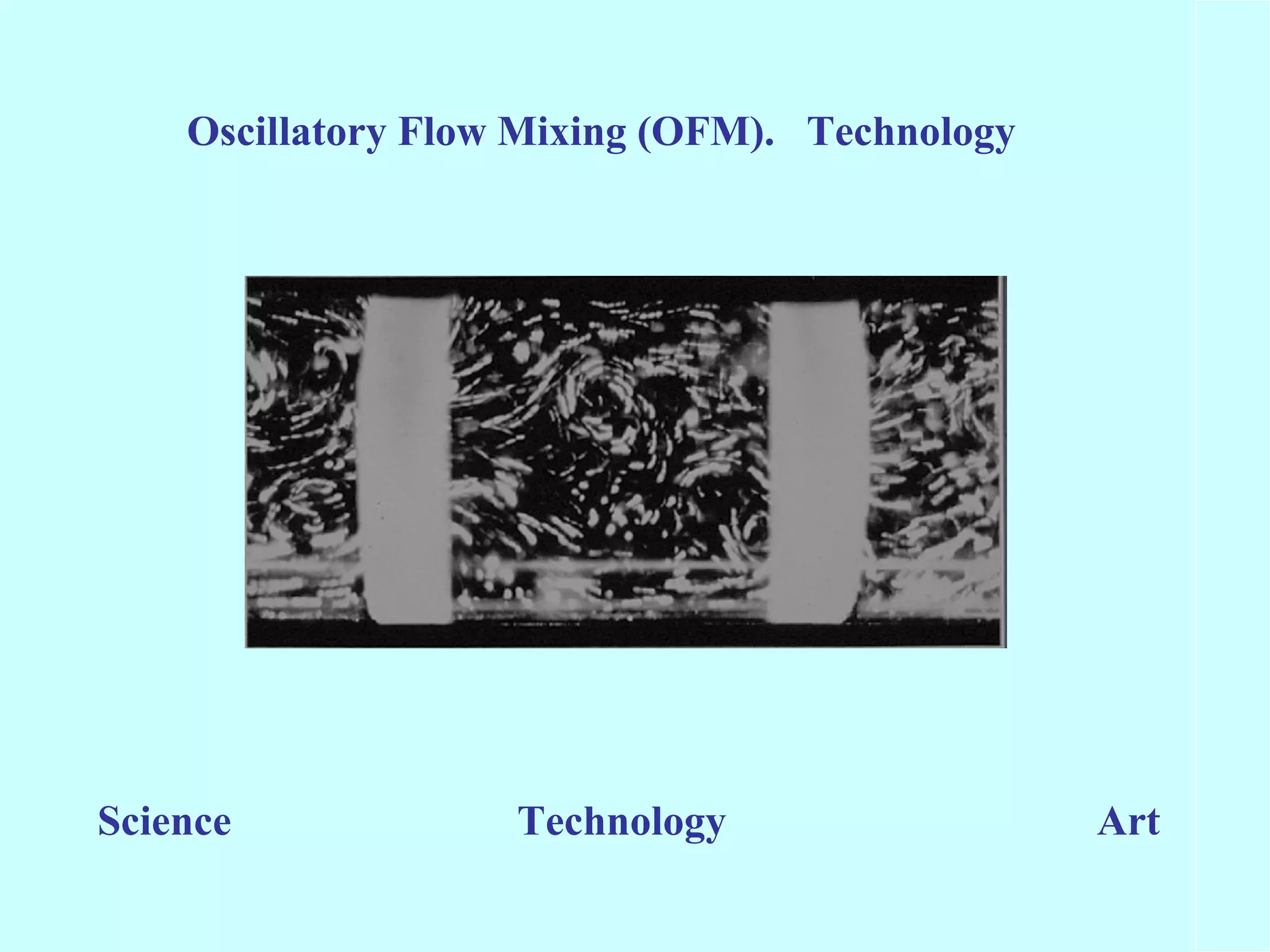

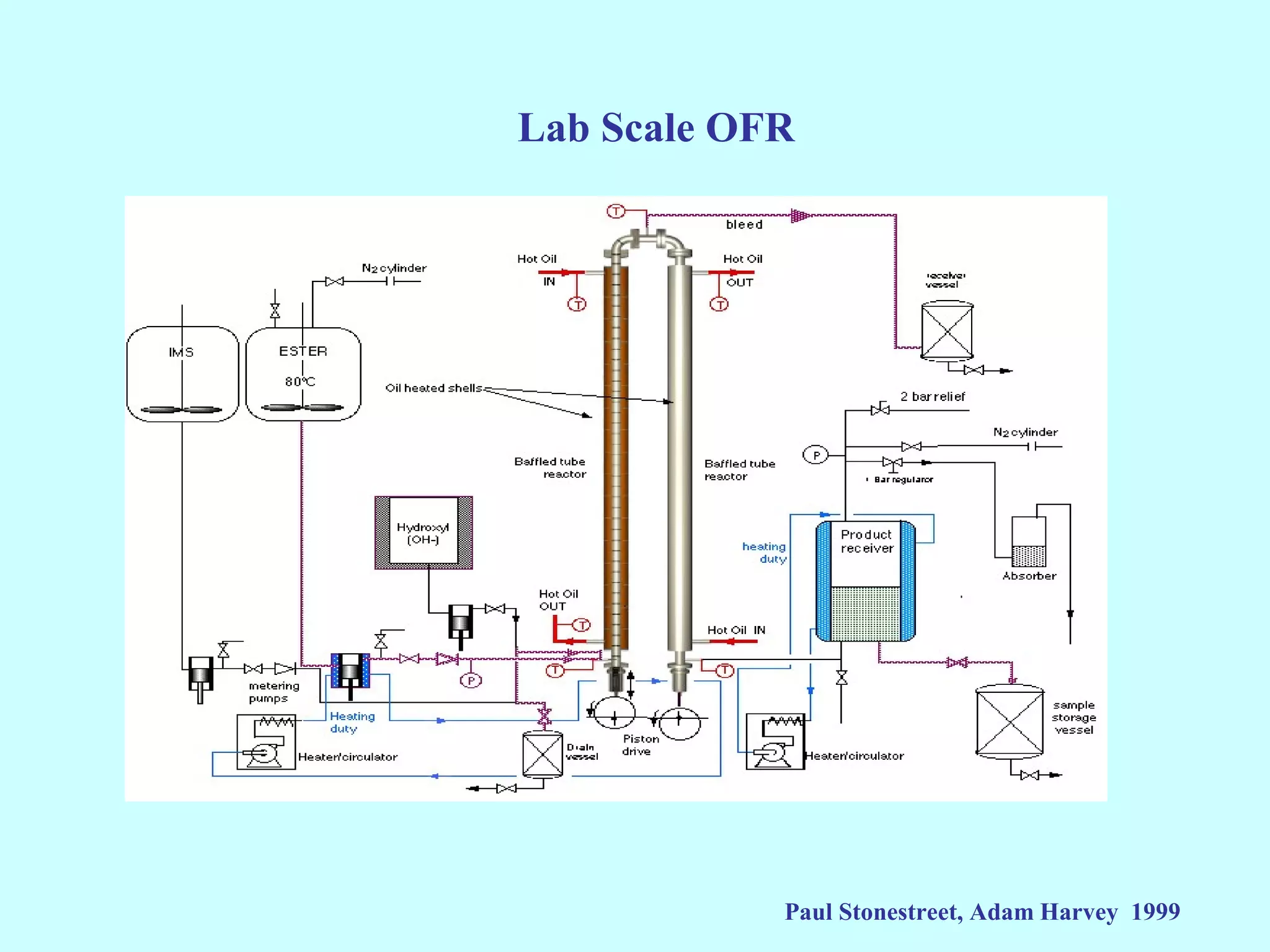

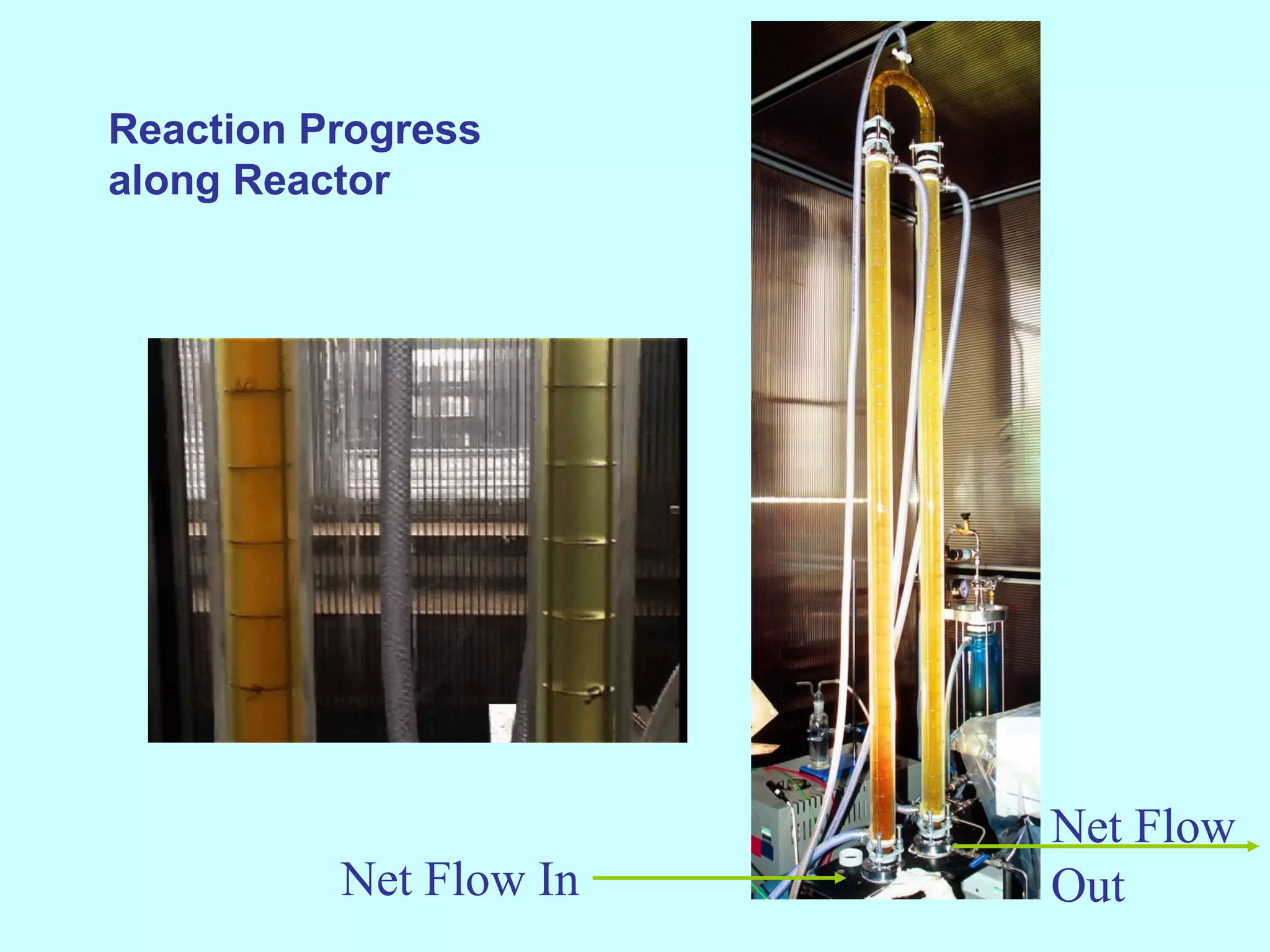

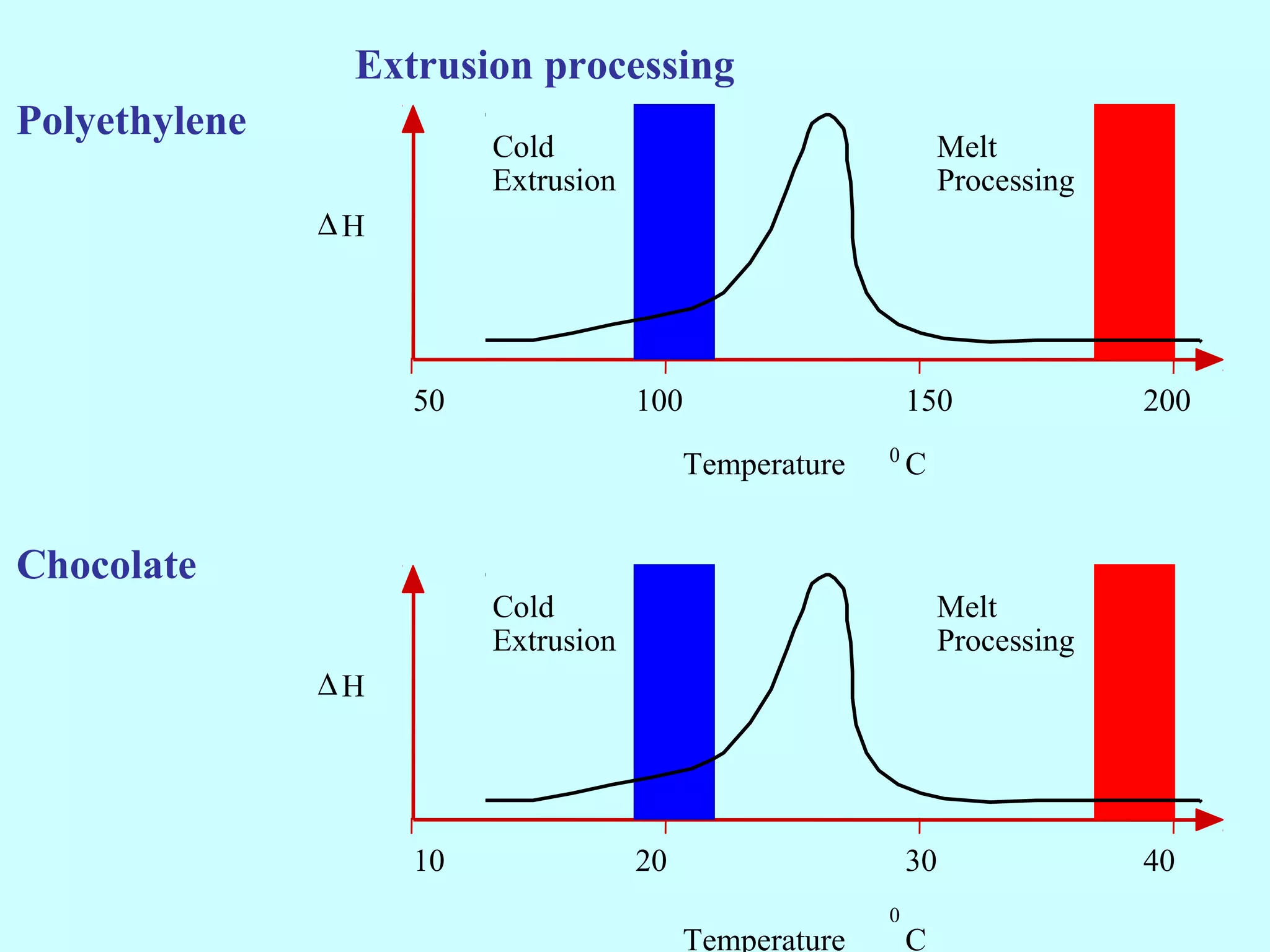

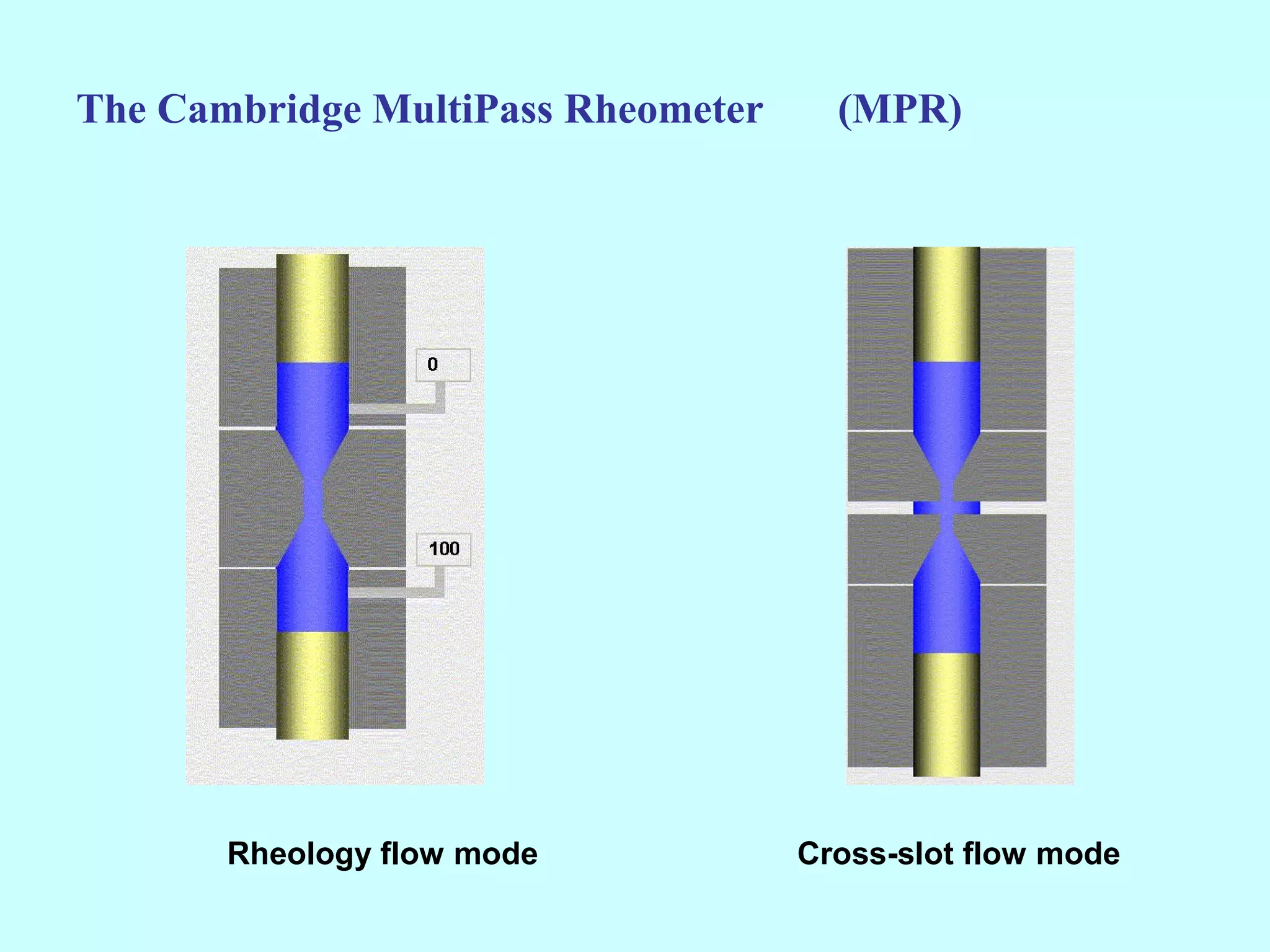

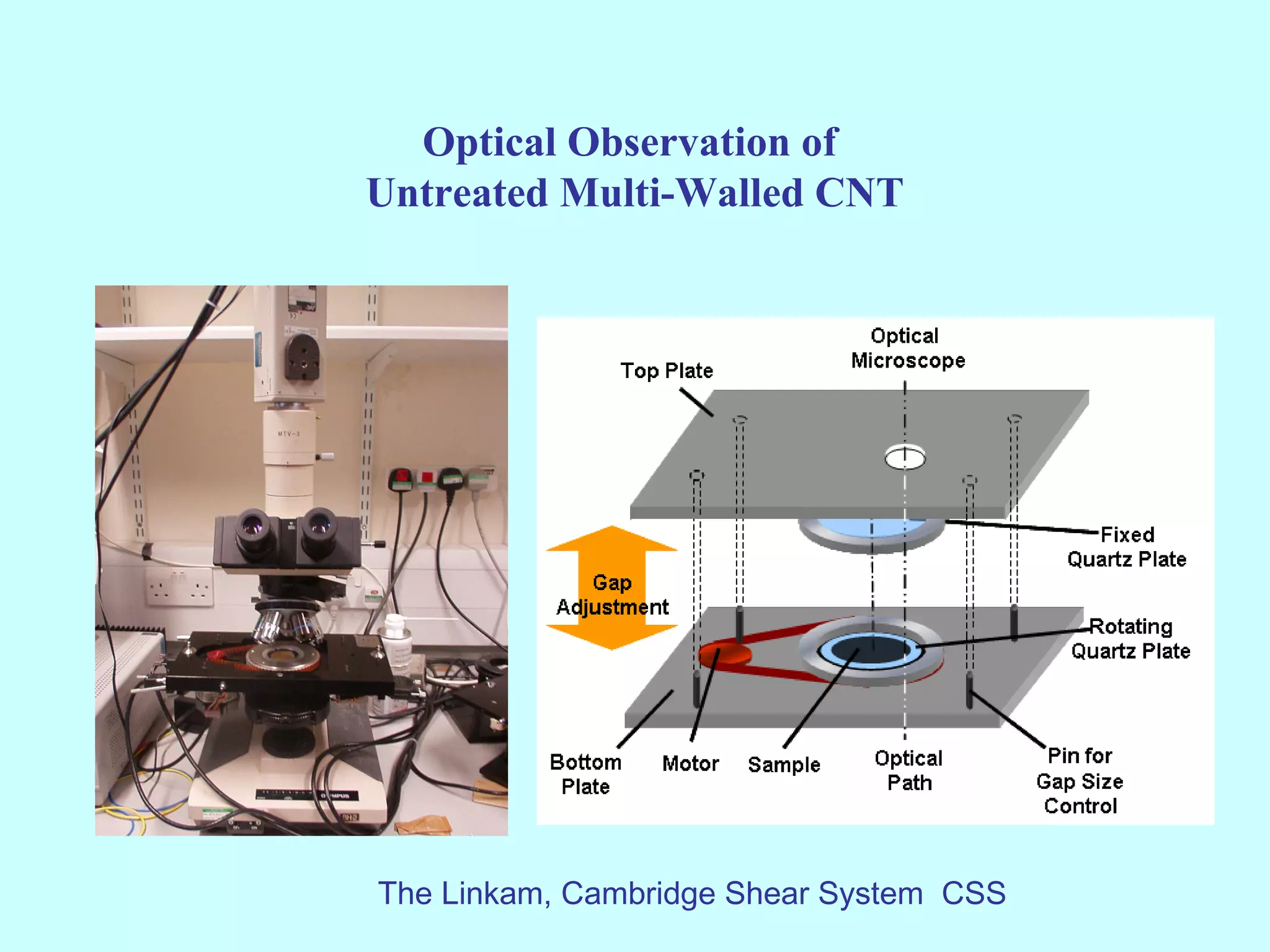

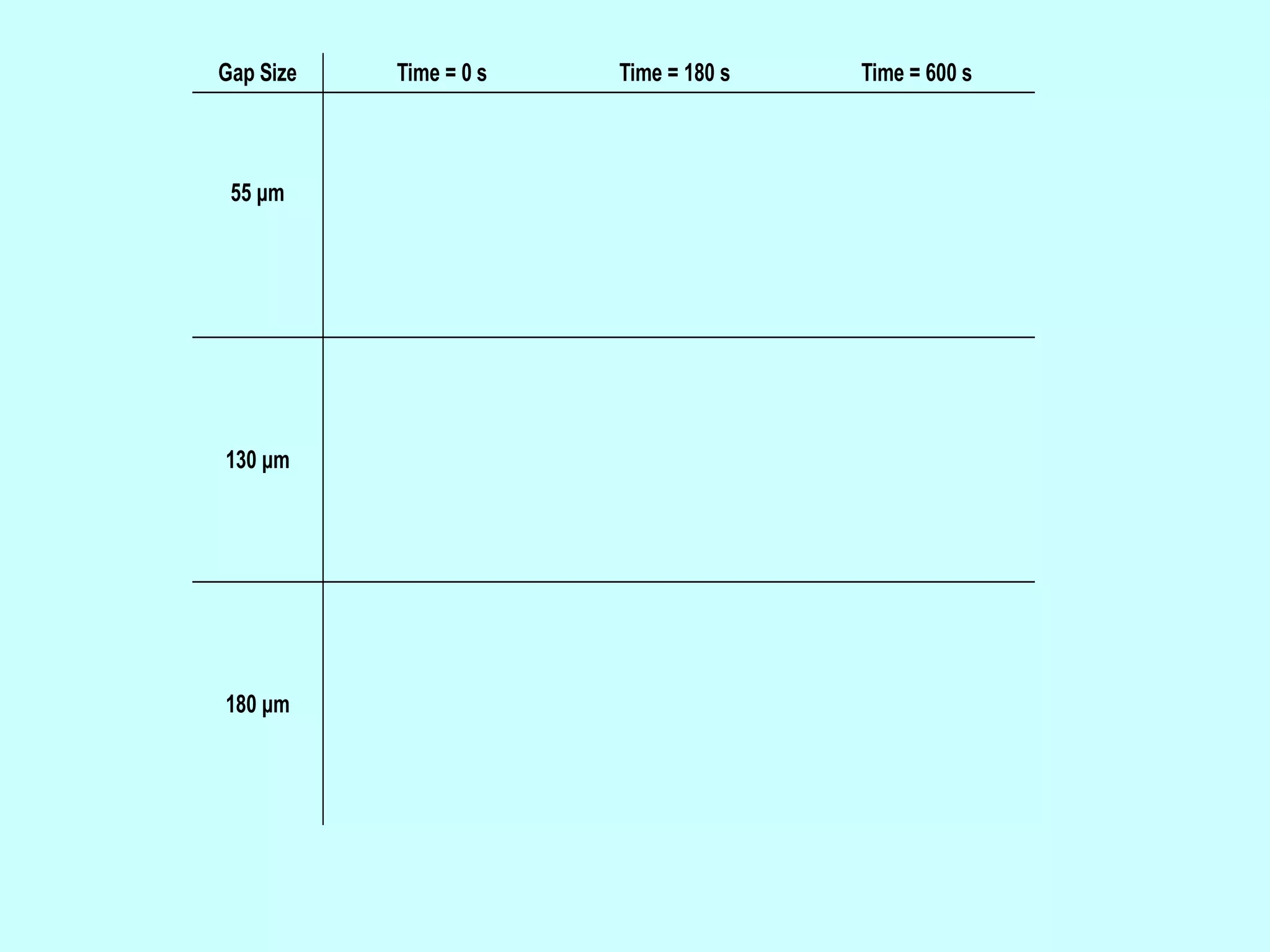

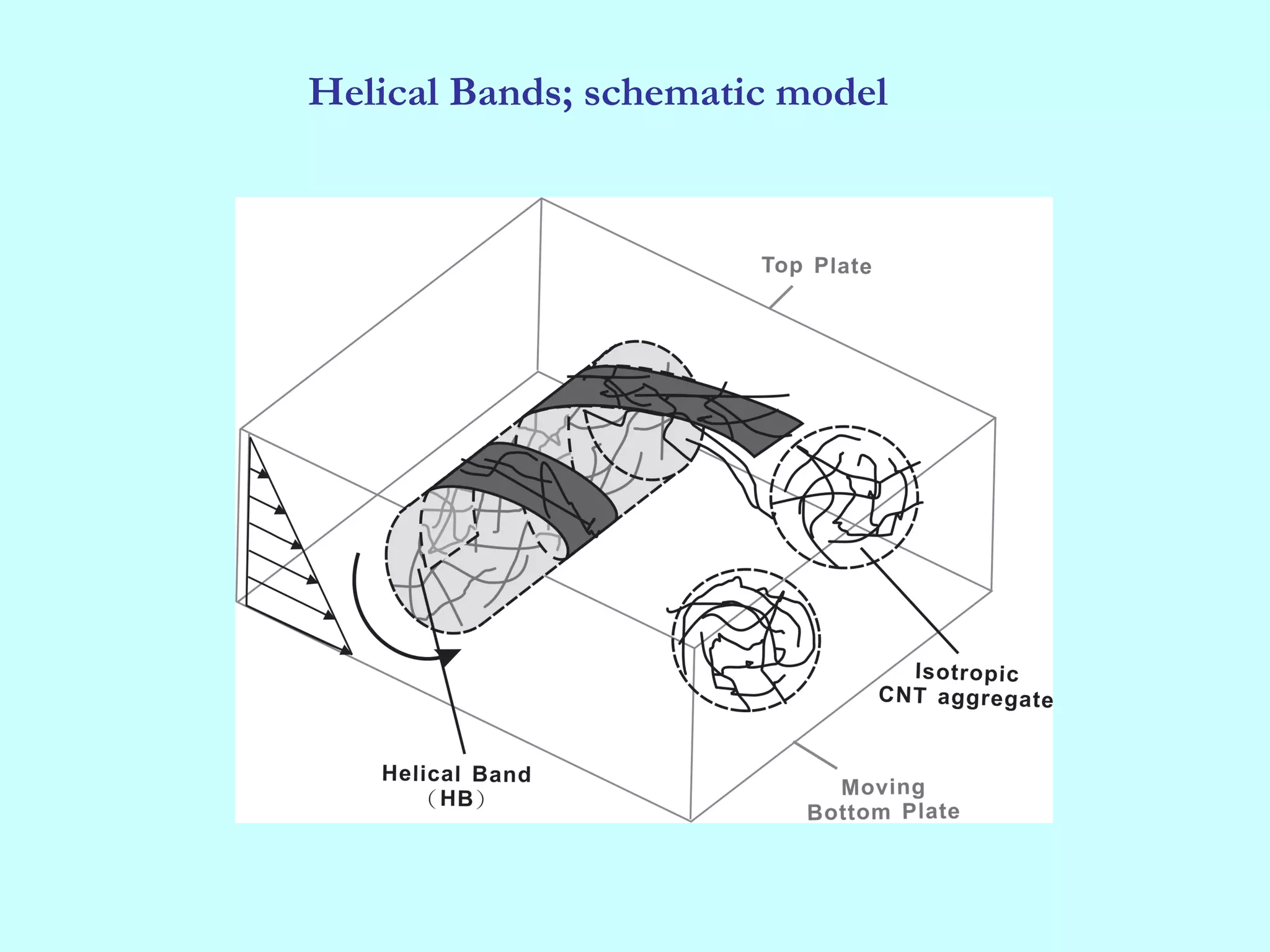

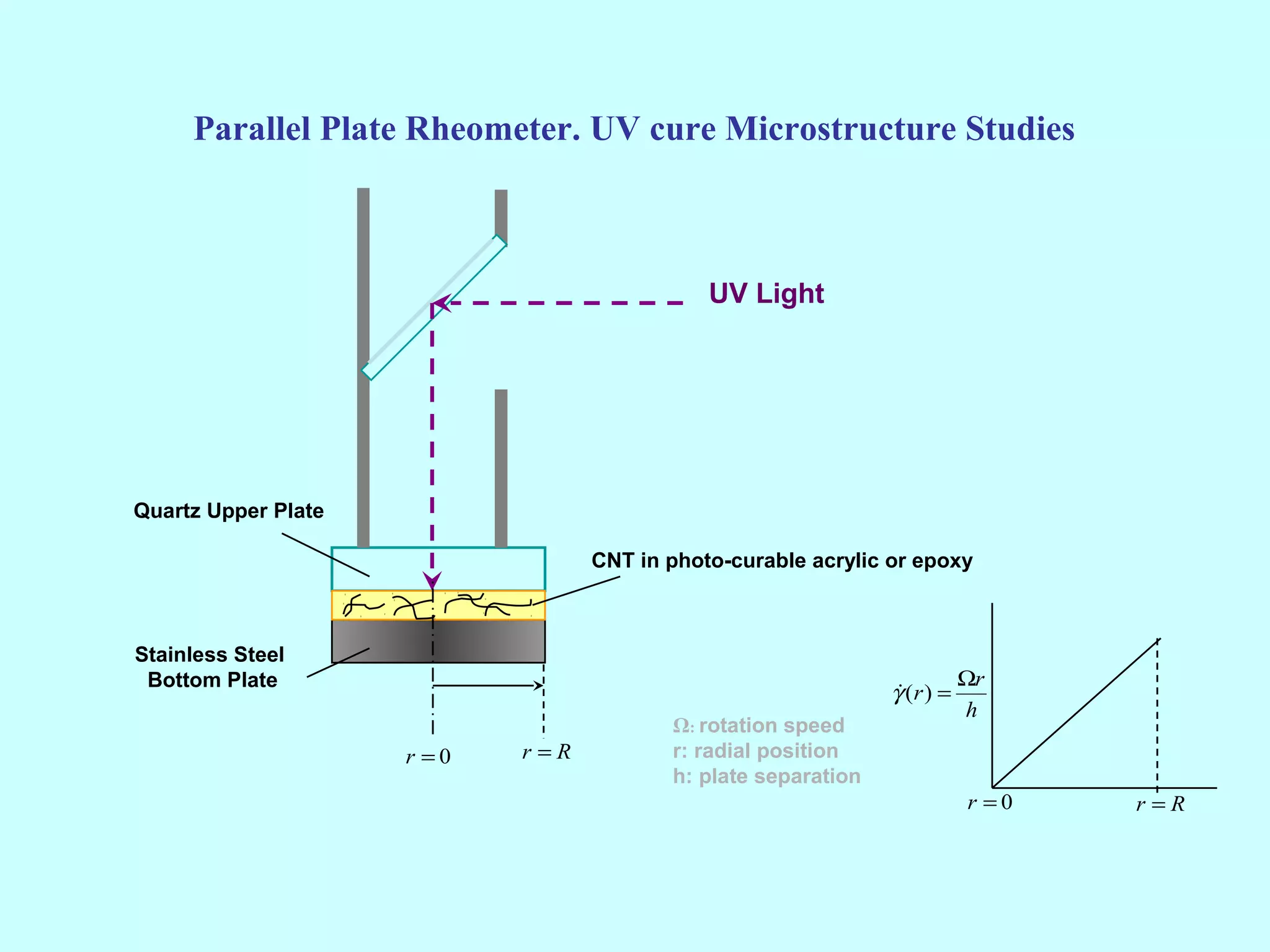

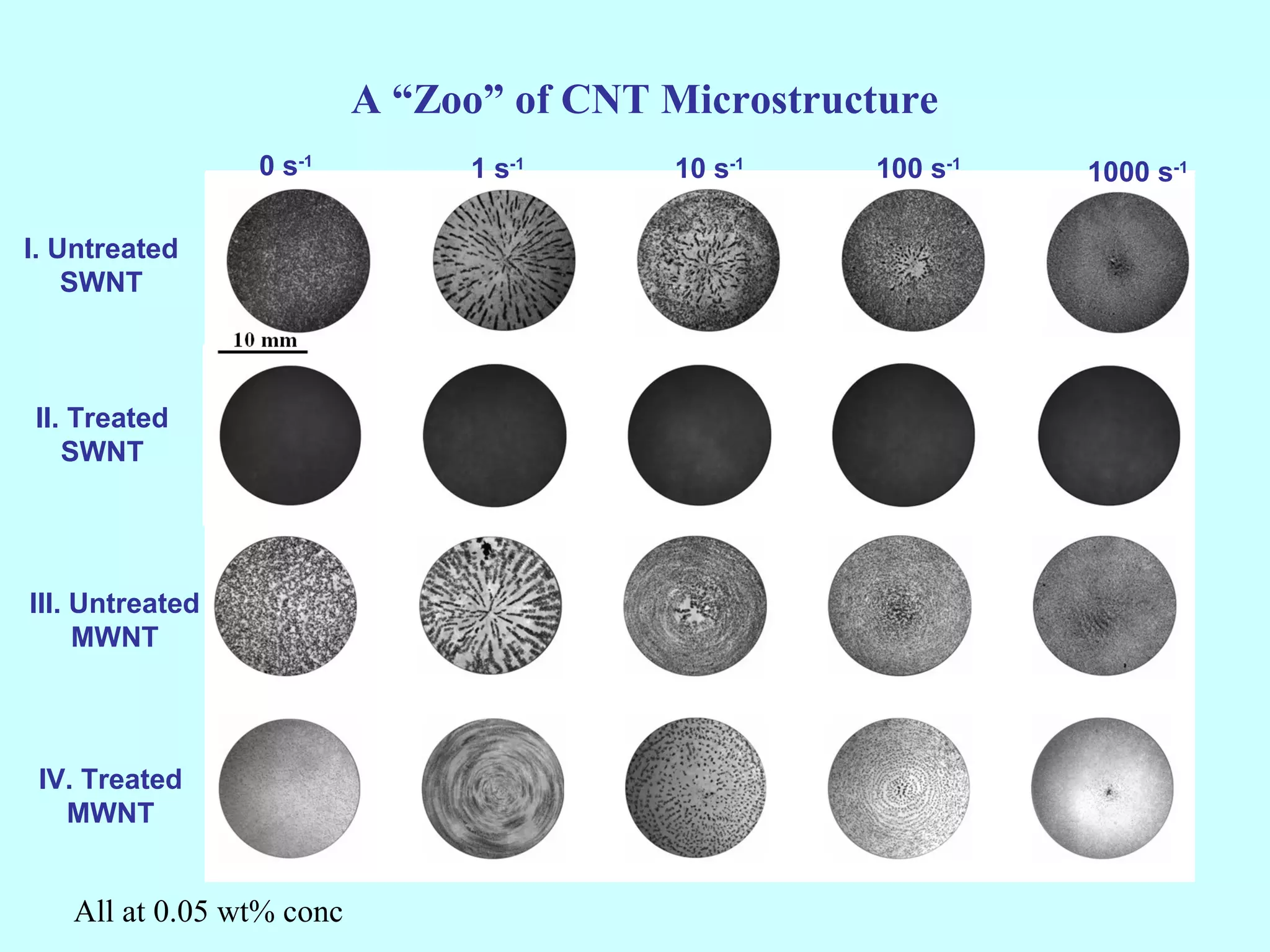

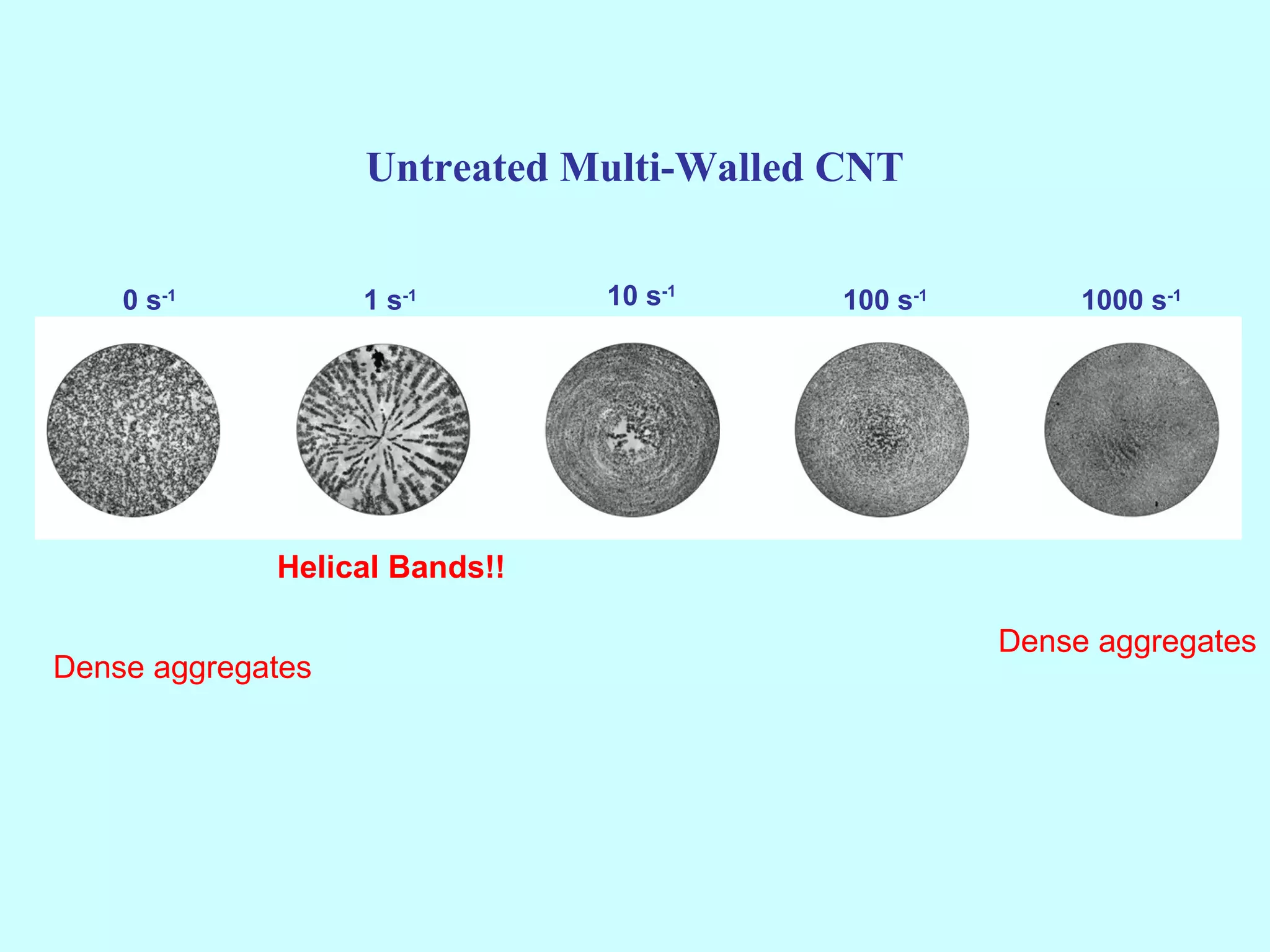

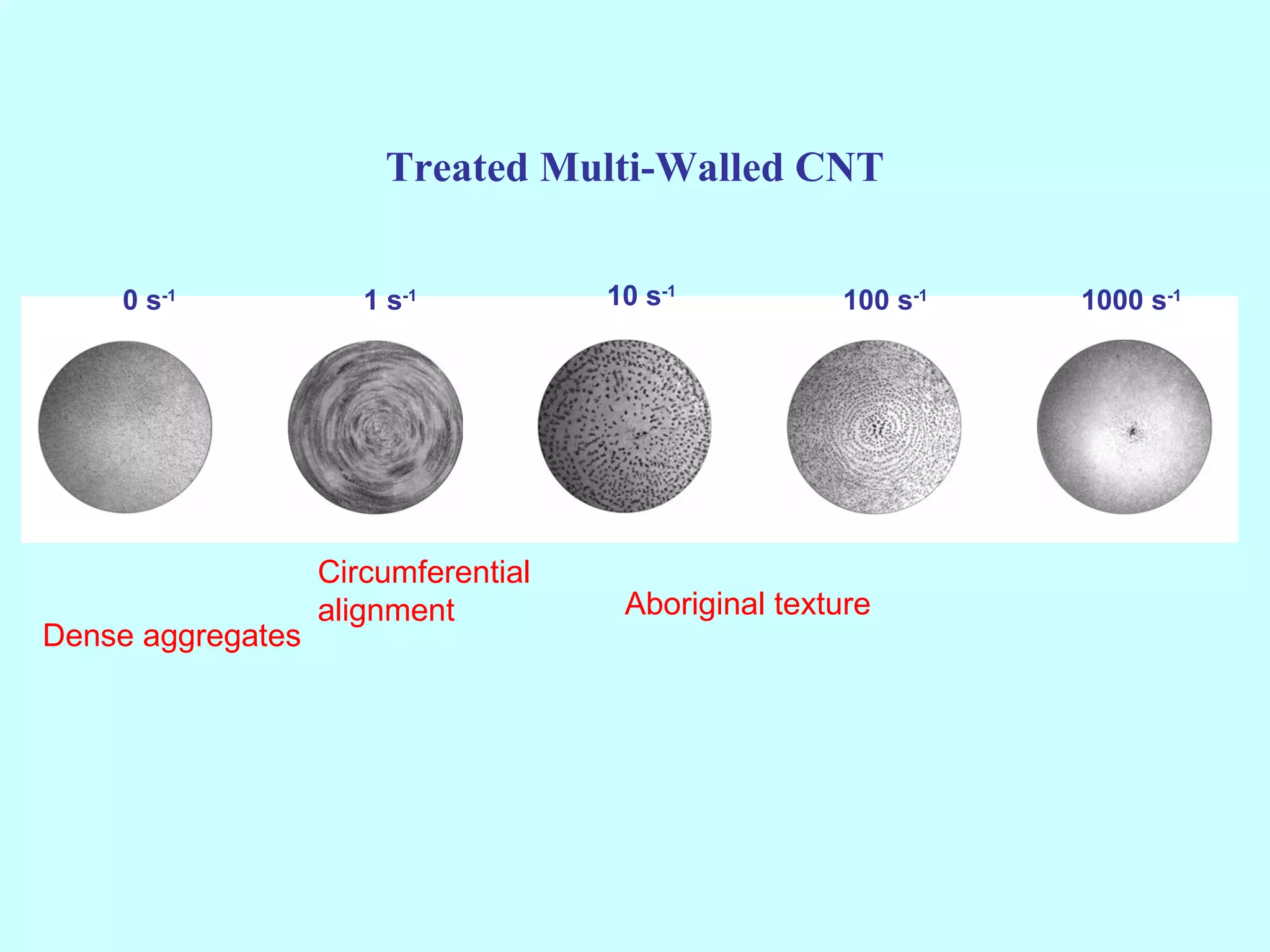

The document summarizes a colloquium presentation by Malcolm Mackley on visualization in the context of physics and engineering, covering historical developments in flow visualization techniques from the 1970s to the present. It highlights various contributors and notable technologies involved in visualizing fluids and materials, including carbon nanotubes and chocolate extrusion processing. The presentation acknowledges the influence of the Bristol Physics Department and its history in advancing the field.