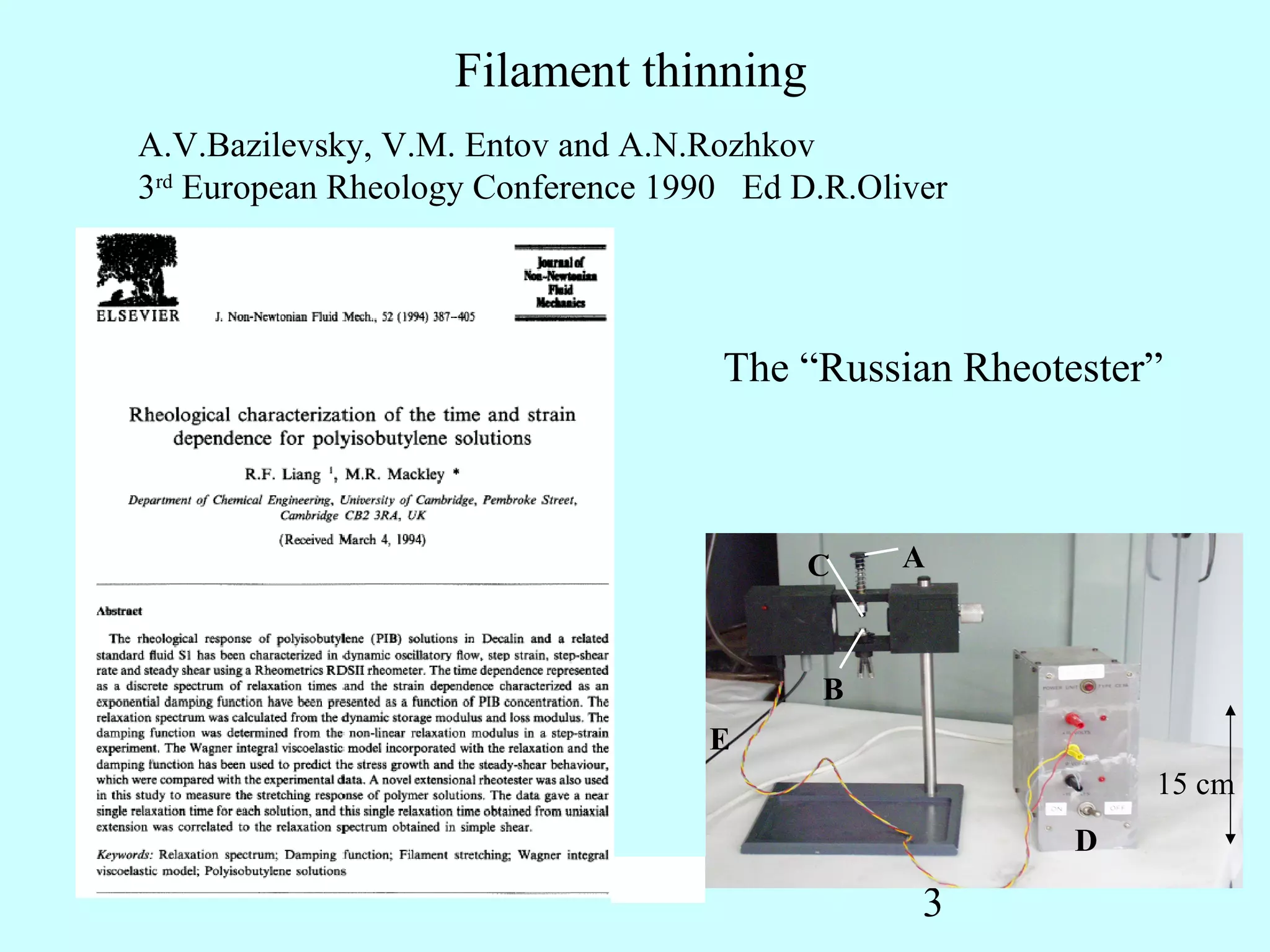

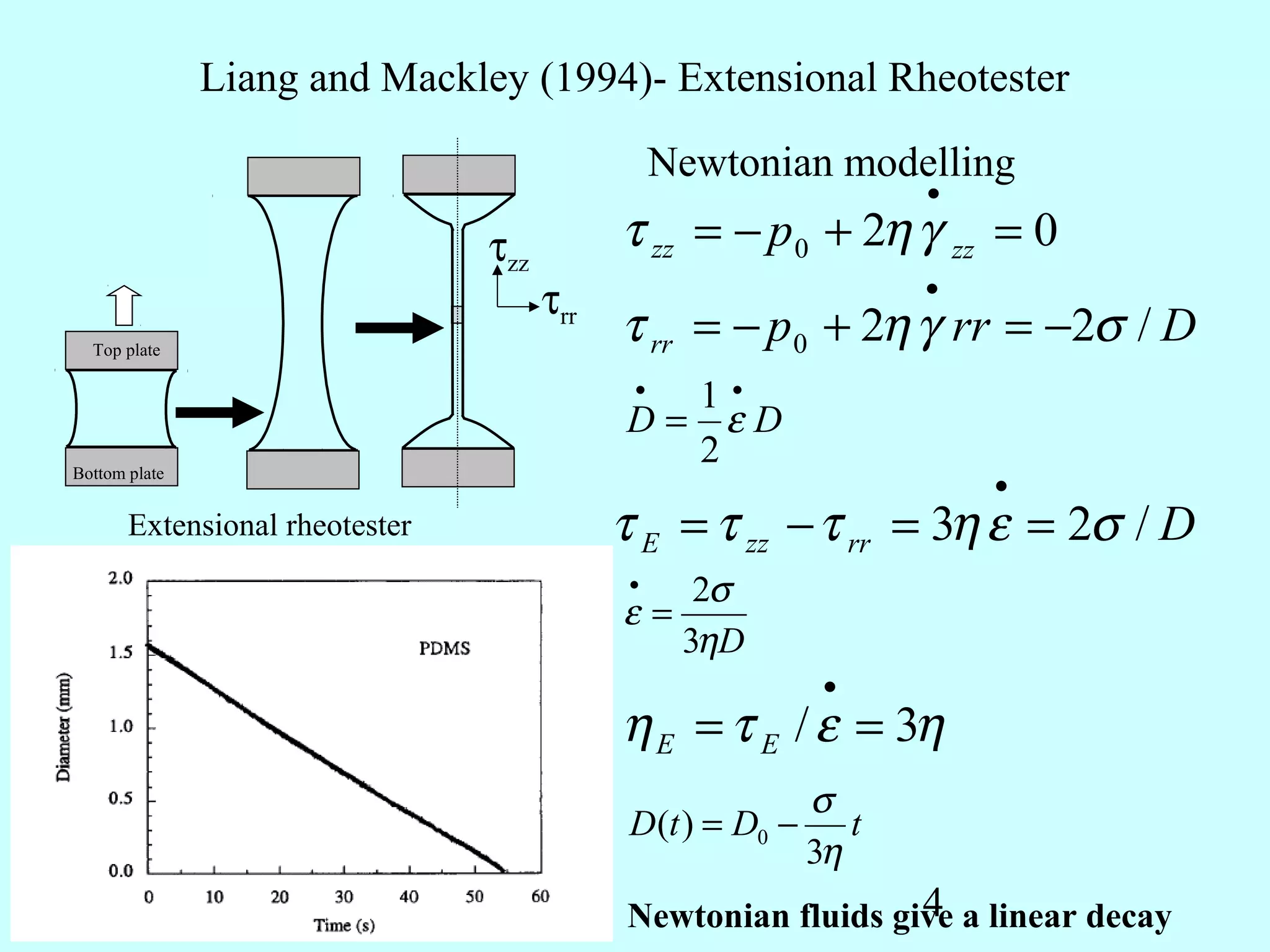

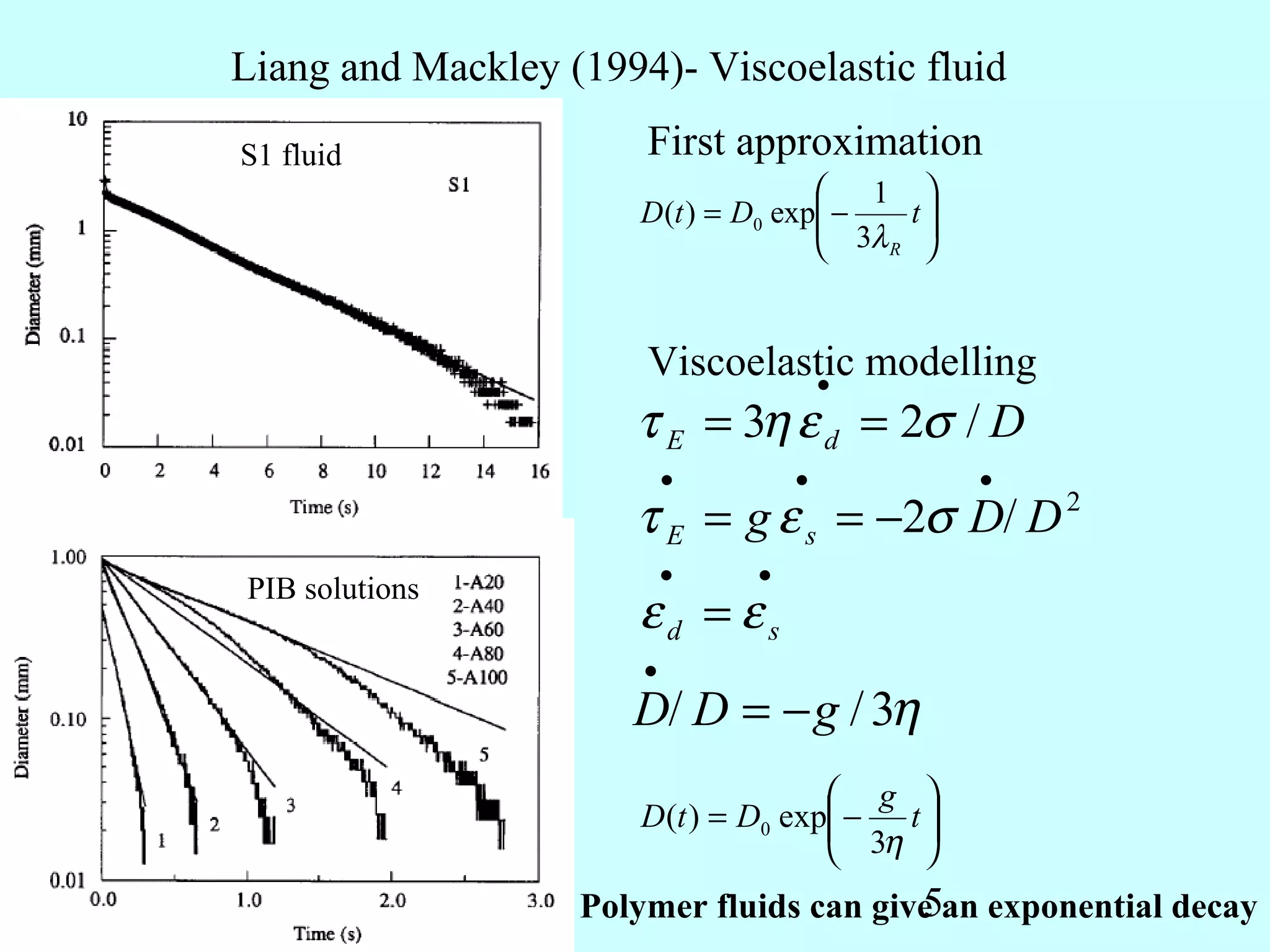

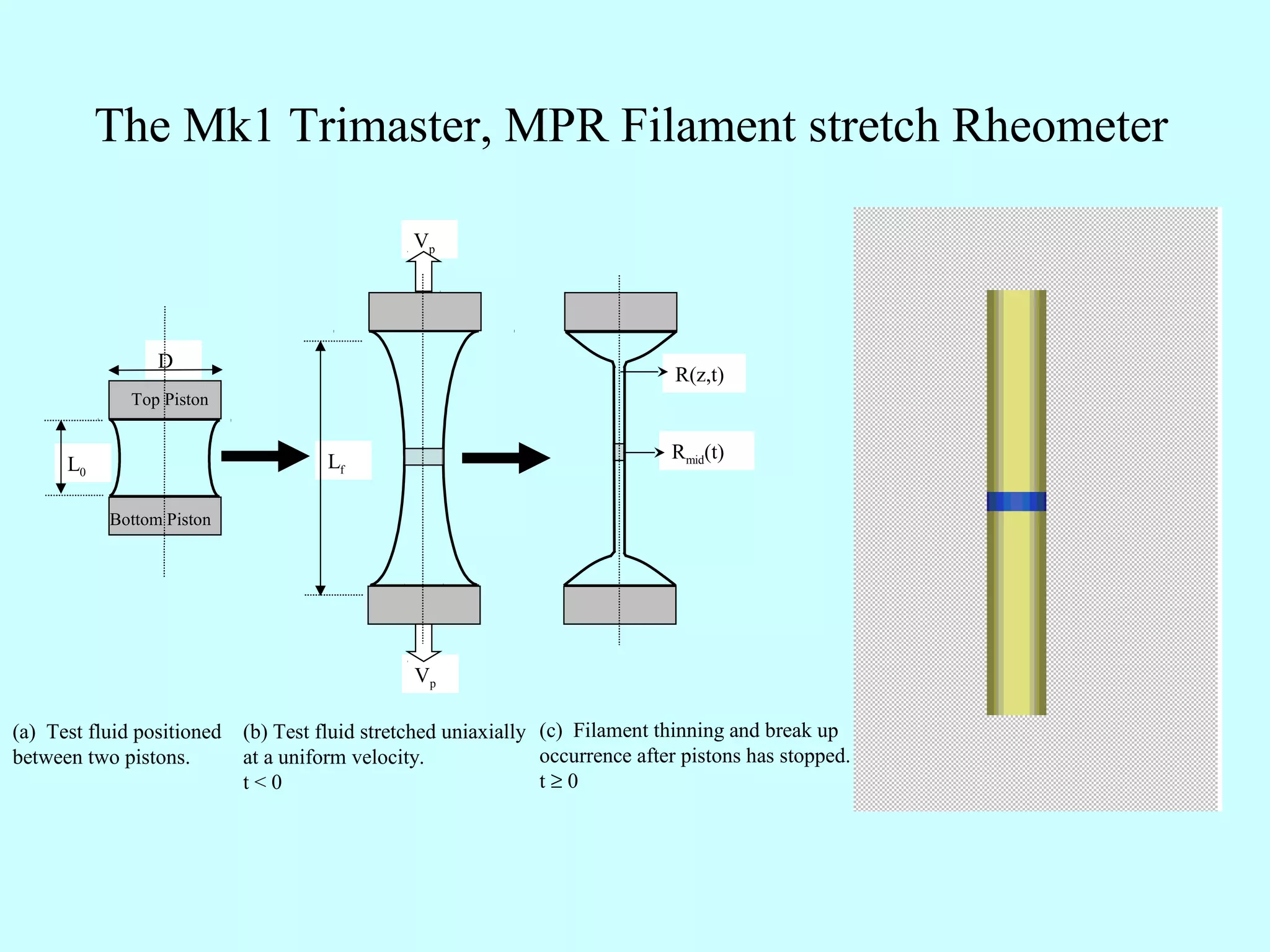

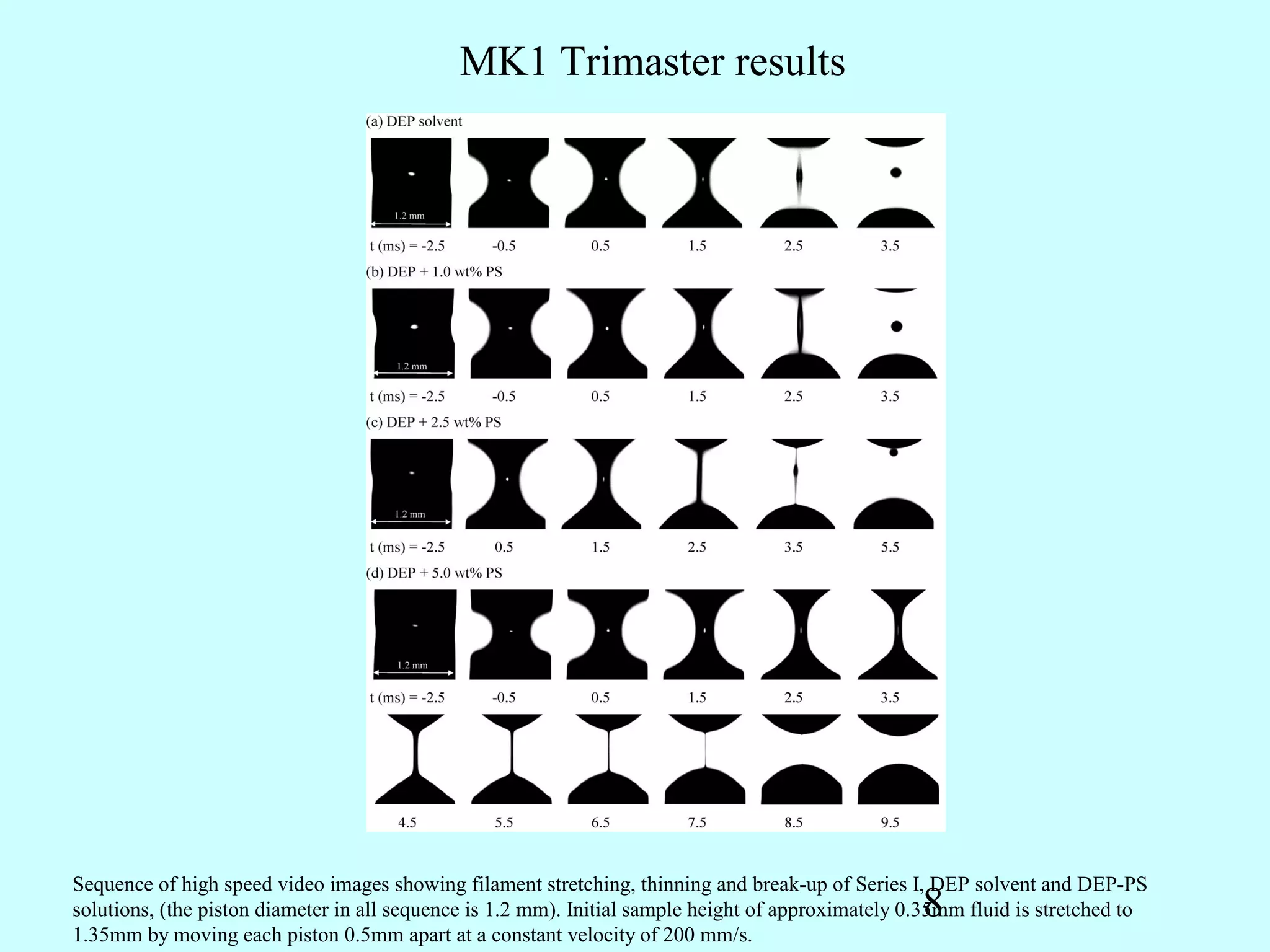

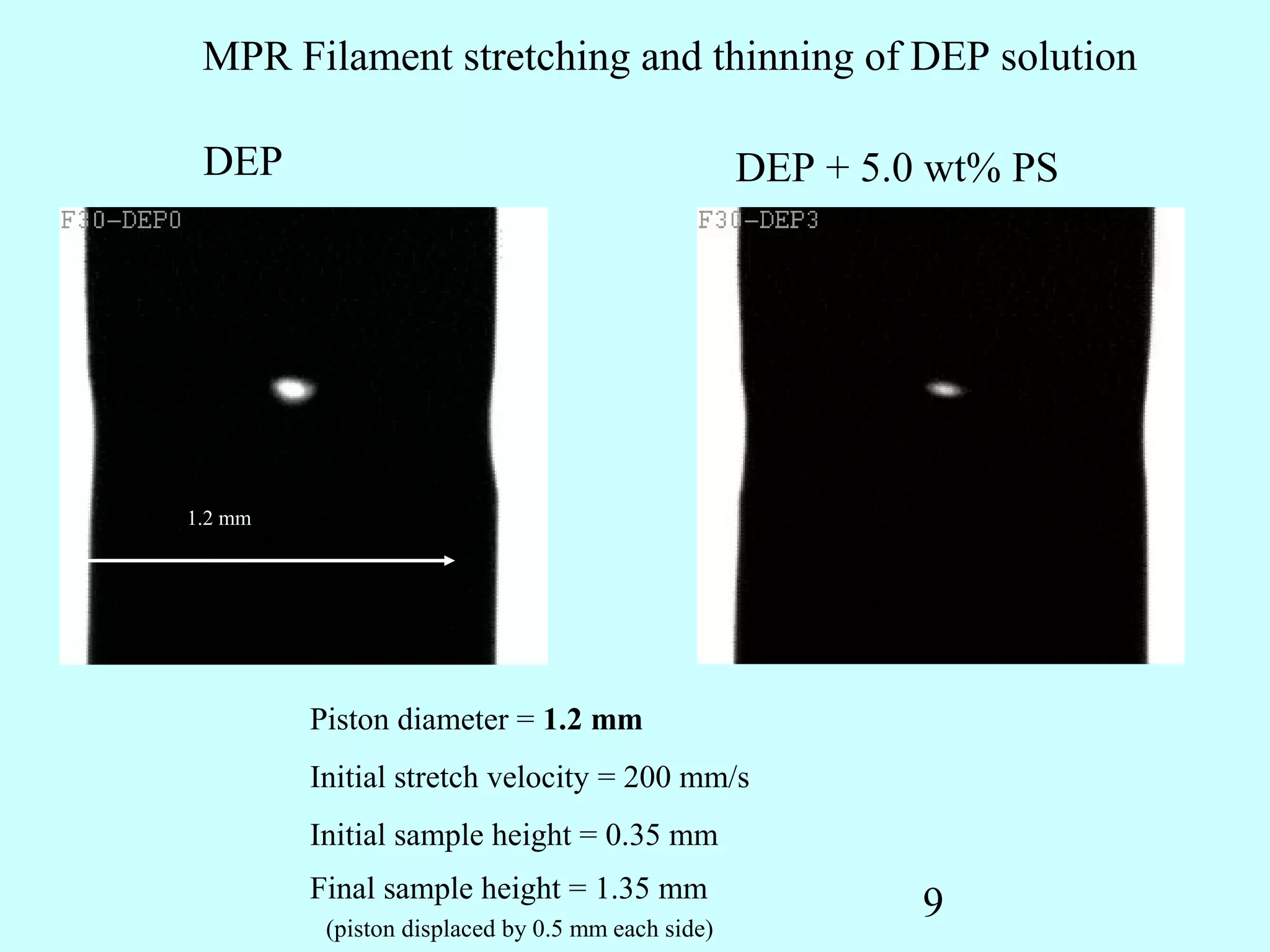

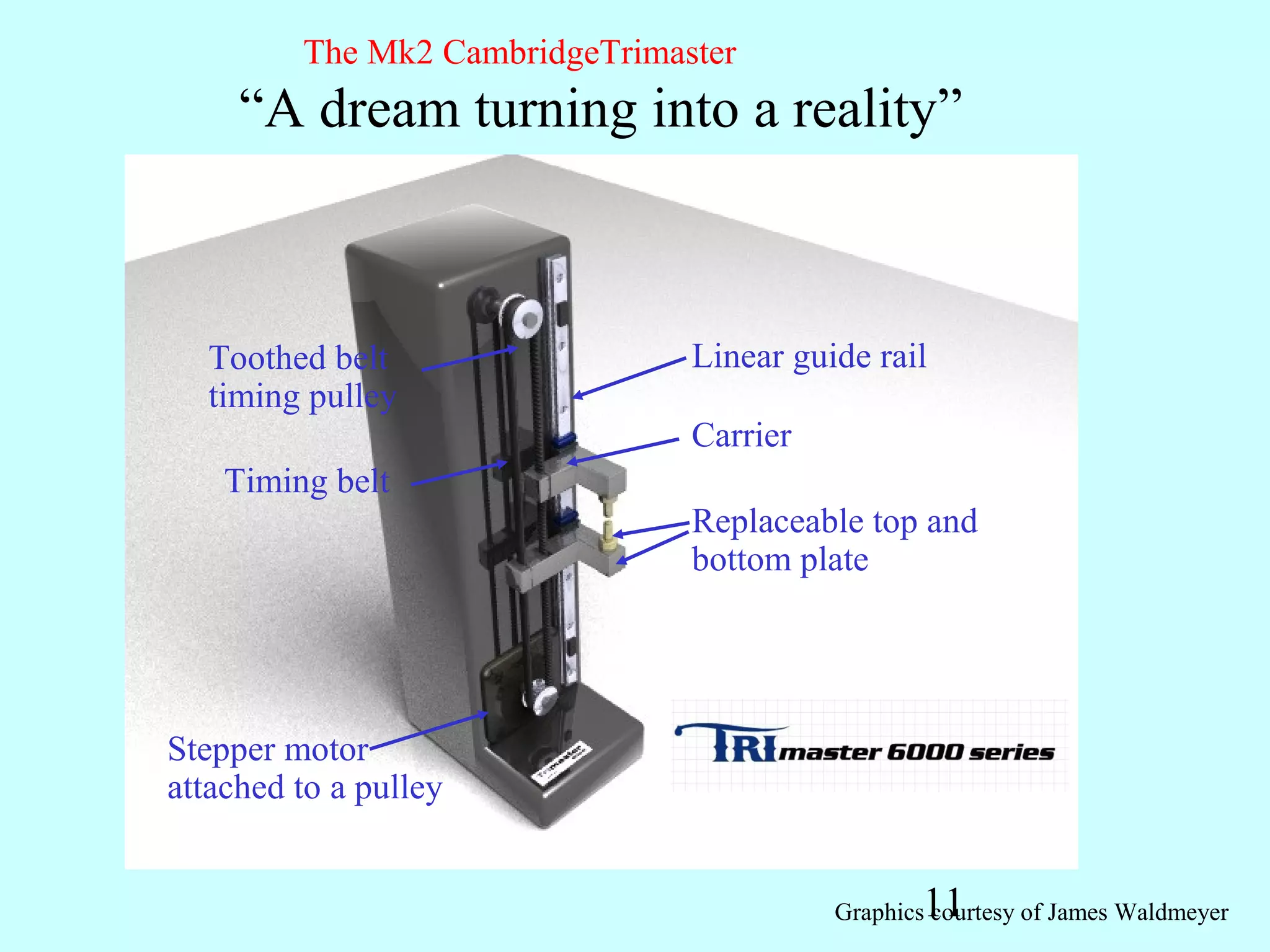

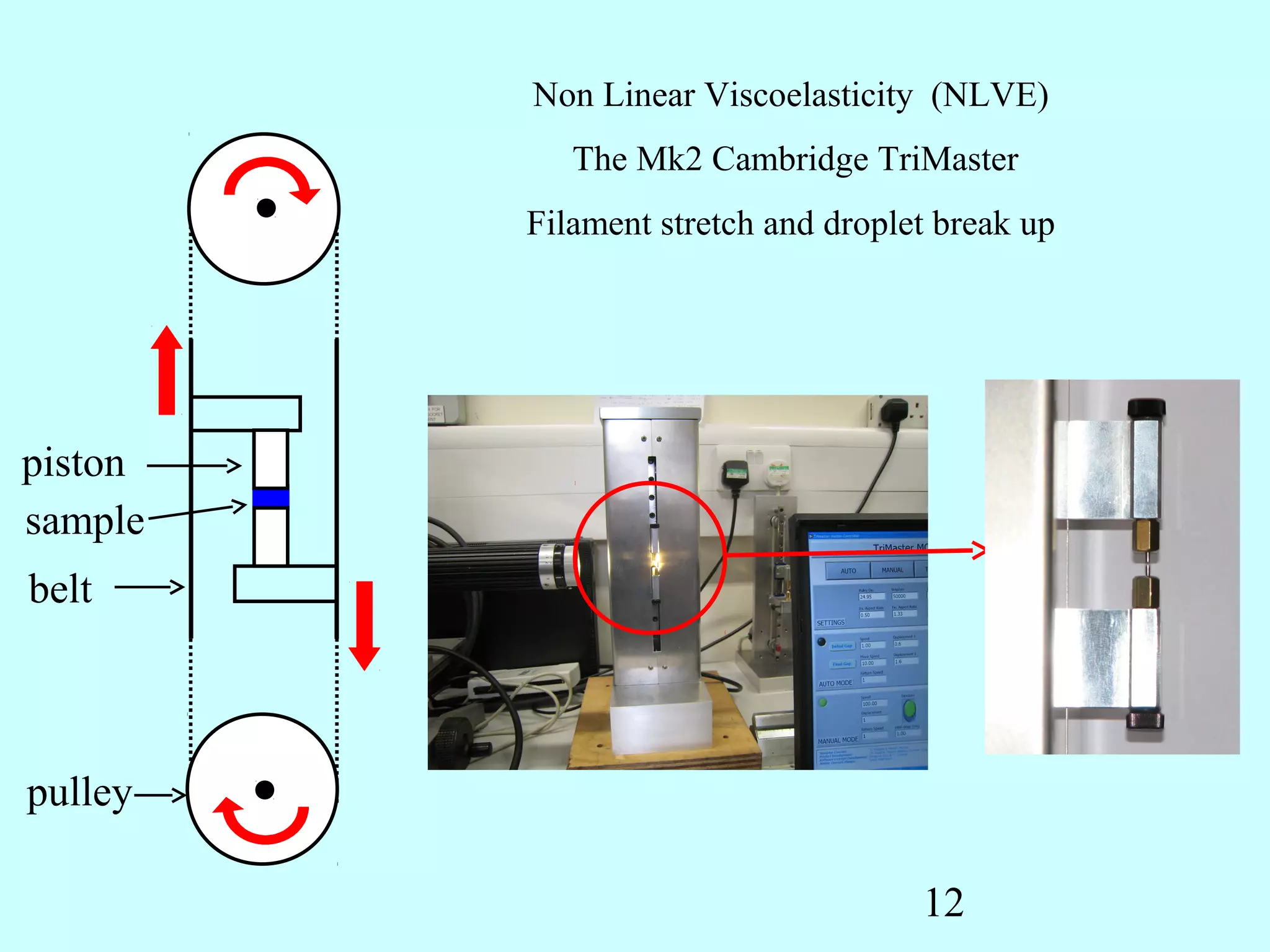

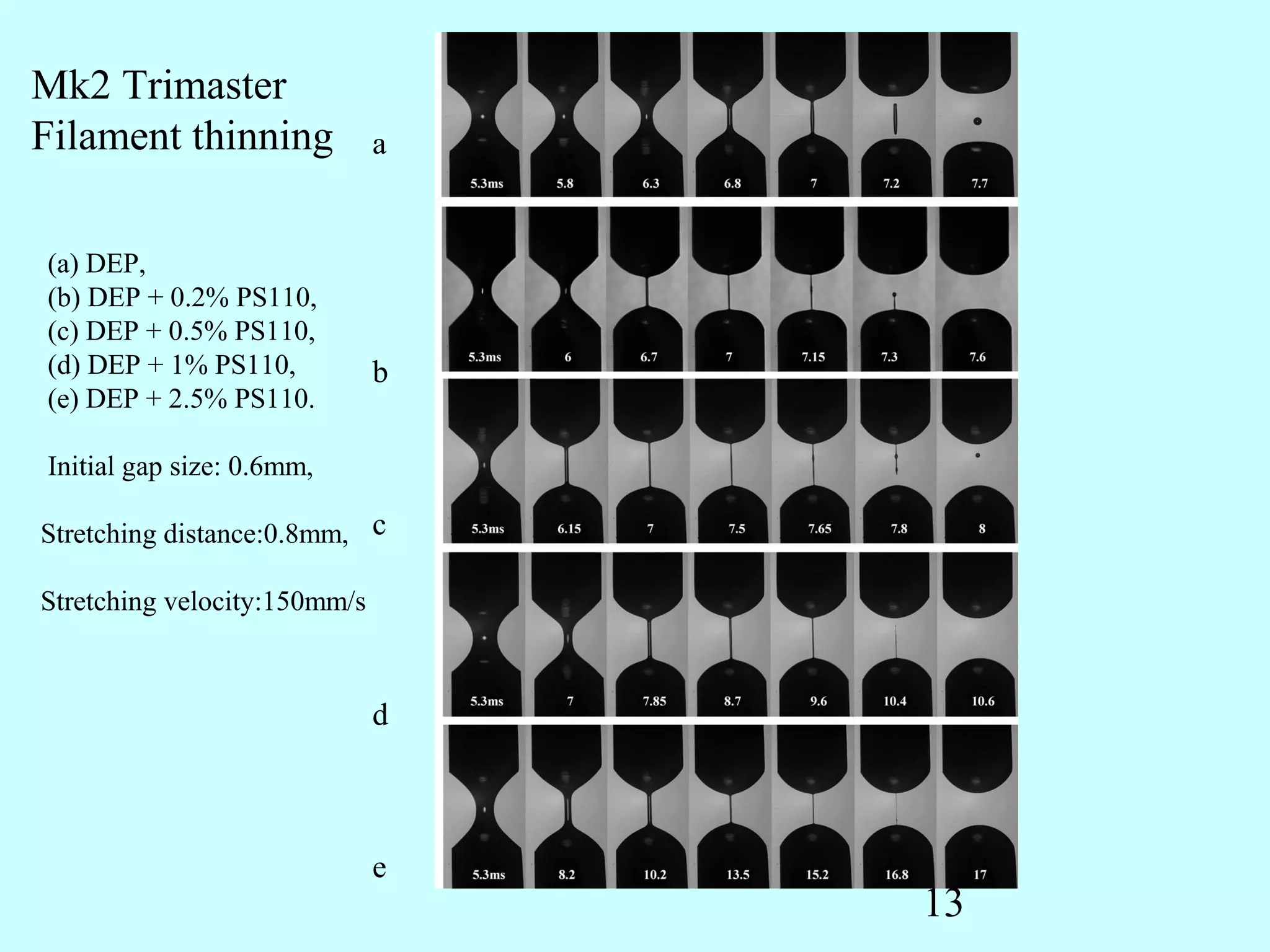

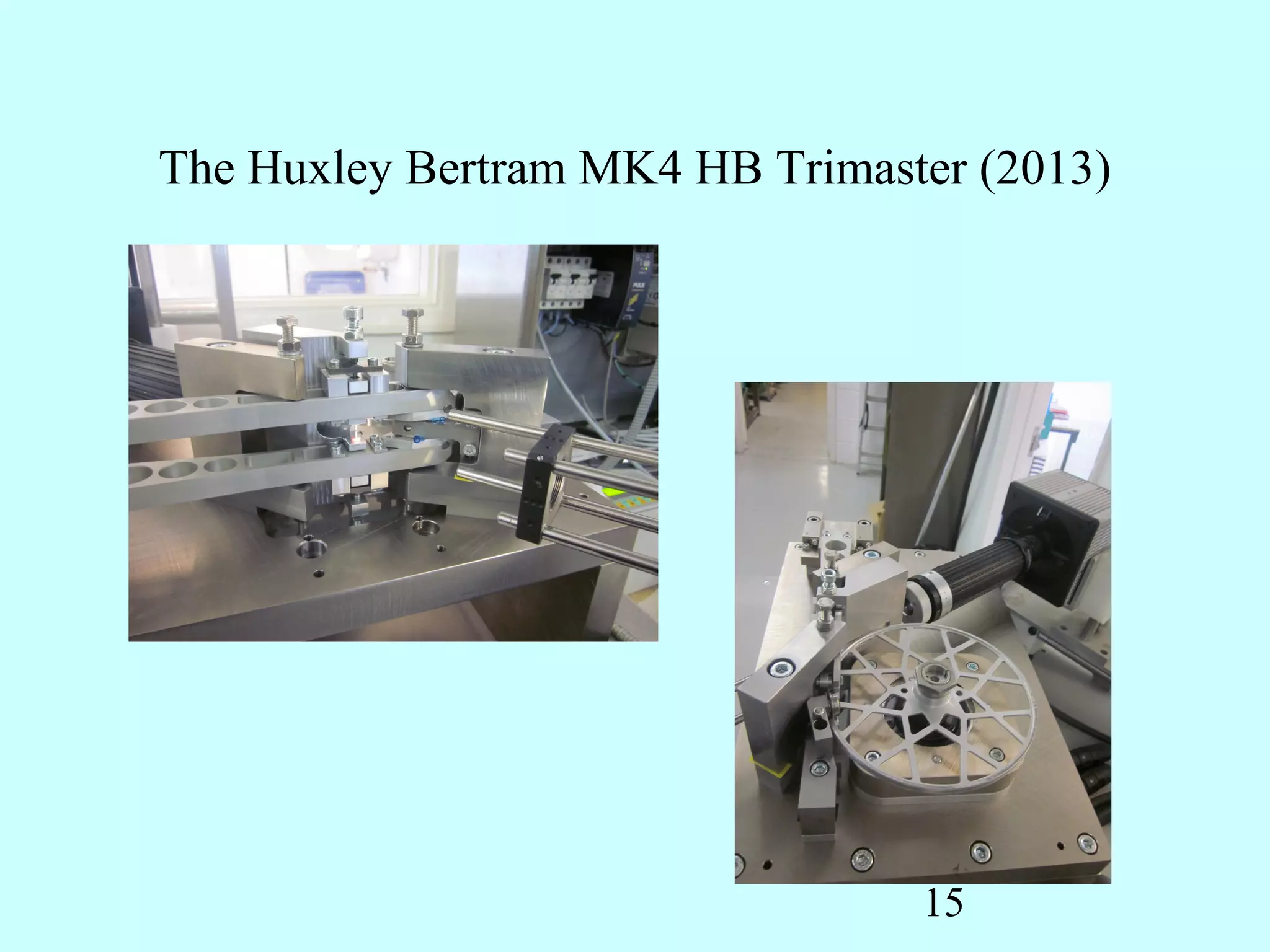

The document discusses the development and evolution of filament stretching and thinning experiments conducted on polymer-based fluids, particularly using the Russian rheometer and subsequent Cambridge trimaster models. It highlights advancements in measurement techniques and the significance of rheology in ink jet applications throughout the 1990s and 2000s. The text details the transition from the mk1 to mk4 Cambridge trimaster, emphasizing innovations in rheometric devices and their operational efficiencies.