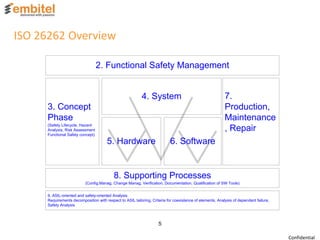

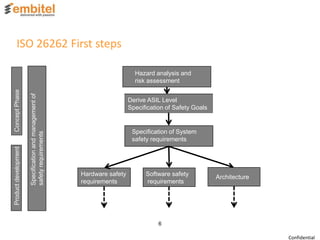

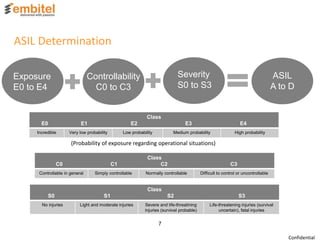

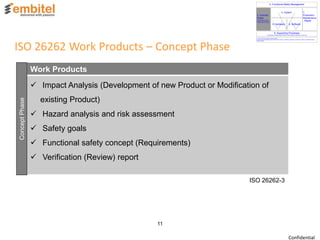

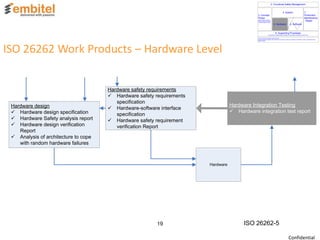

This webinar discusses ISO 26262 and functional safety for automotive projects. The speaker, Mr. Martin Heininger, has 15 years of experience working on functional safety projects. He will cover an overview of ISO 26262, the first steps of compliance, ASIL determination, work products required at different stages of the automotive safety lifecycle, methods for software unit implementation, and a collaboration between Embitel and Heicon for ISO 26262 consultancy services. The webinar aims to introduce functional safety standards and processes to enable compliant product development for automotive systems.