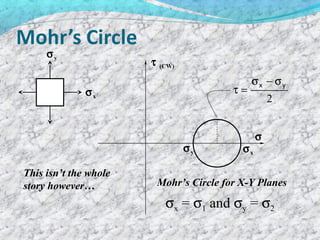

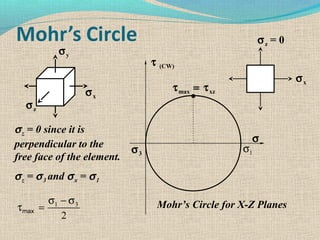

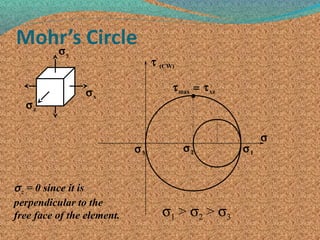

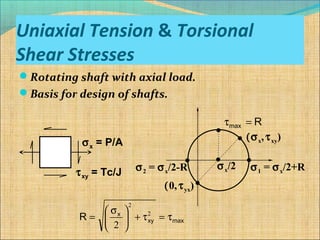

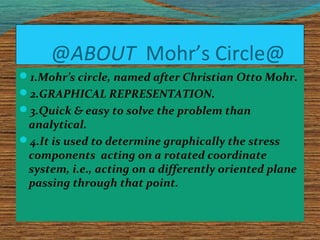

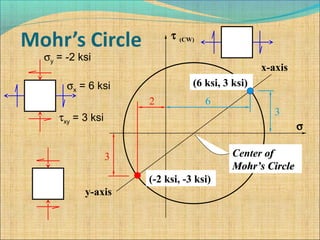

1. Mohr's circle is a graphical representation used to determine stress components acting on a rotated plane passing through a point on a part.

2. It relates normal and shear stresses on the original x-y plane to those on a rotated plane using equations that define a circle.

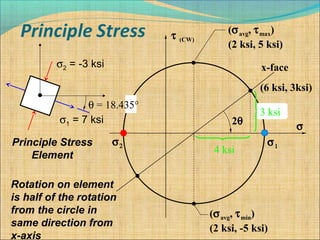

3. Key values like maximum and minimum principal stresses that correspond to points on the circle can be read off to understand how stress changes with rotation.

![@FORMULA@

MAX. PRINCIPLE STRESS=>

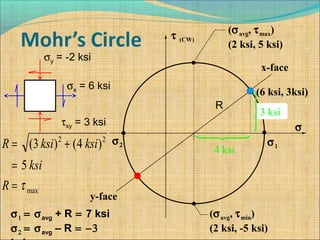

(X+Y)/2+[{(X-Y)/2}^2+(Zxy)^2]^(.5)=C+R

MIN. PRINCIPLE STRESS=>

(X+Y)/2-[{(X-Y)/2}^2+(Zxy)^2]^(.5)=C-R

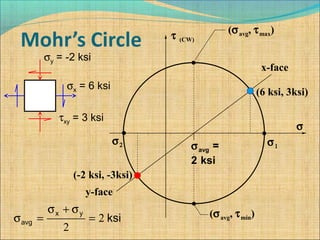

COORDINATE(C)=(X+Y)/2

RADIUS OF CIRCLE(R)=[{(X-Y)/2}^2+(Zxy)^2]^(.5)

Where X=Stress in x-direction, Y=Stress in y-

direction and Zxy=Shear stress.](https://image.slidesharecdn.com/mohrscircle-samriddha1-170506102814/85/Mohr-s-circle-Samriddha-Shil-S-S-3-320.jpg)

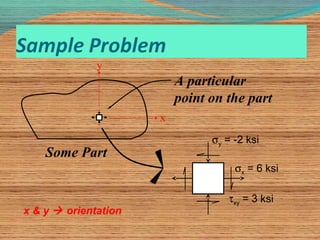

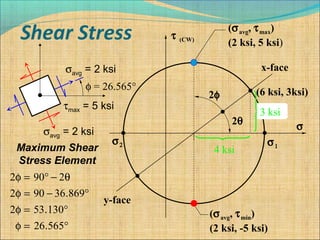

![σavg = 2 ksi

σavg = 2 ksi

τmax = 5 ksi

φ = 26.565°

σ1 = 7 ksi

σ2 = -3 ksi

σx = 6 ksi

σy = -2 ksi

τxy = 3 ksi

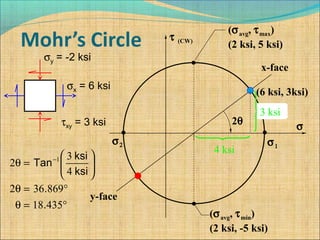

θ = 18.435°

θ+ φ = 18.435 ° + 26.565 ° = 45 °,[Z=(X1-Y1)/2 sin2#+Zxy cos2#],

Where #=45*, Now we get Zmax=(X1-Y1)/2.](https://image.slidesharecdn.com/mohrscircle-samriddha1-170506102814/85/Mohr-s-circle-Samriddha-Shil-S-S-11-320.jpg)