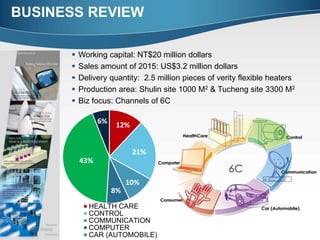

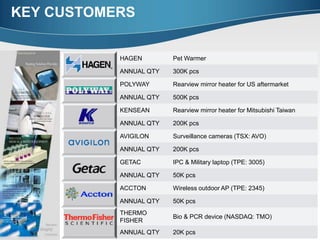

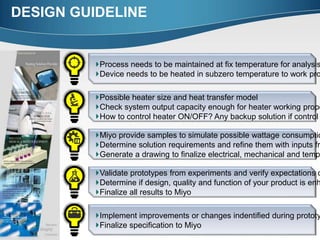

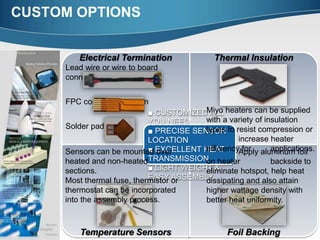

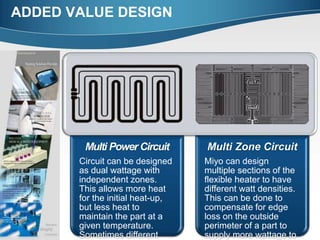

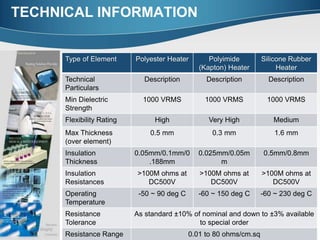

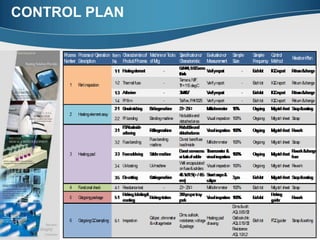

Miyo Technology is a manufacturer of flexible heaters that provides heating solutions to various industries. They have two production sites in Taiwan and produce over 2.5 million flexible heaters per year. Their products include polyester, polyimide, and silicone rubber heaters that can withstand temperatures up to 230°C and power densities of 8W/cm2. Miyo works closely with customers to customize heaters through design, integration of sensors, and electrical terminations.