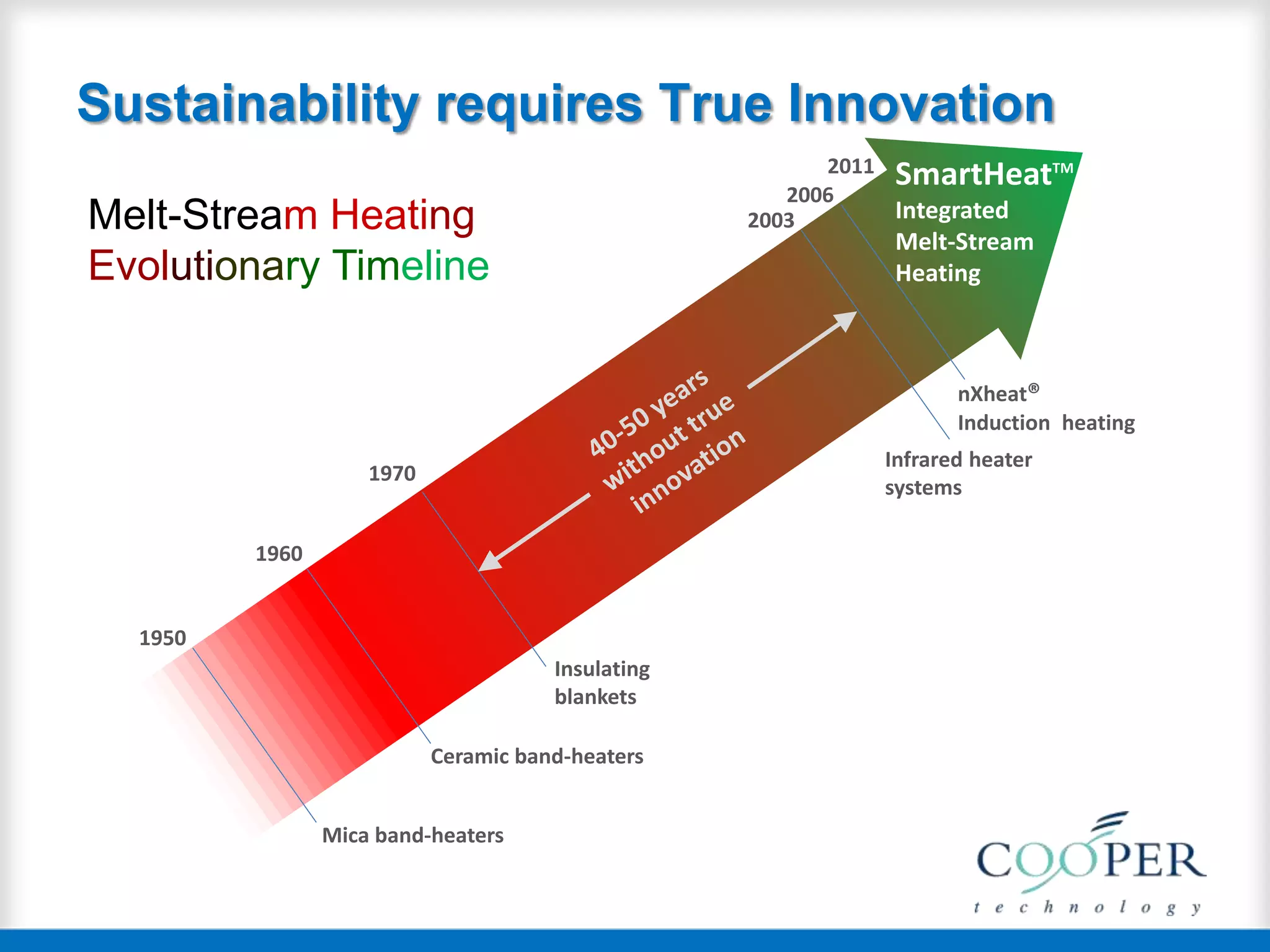

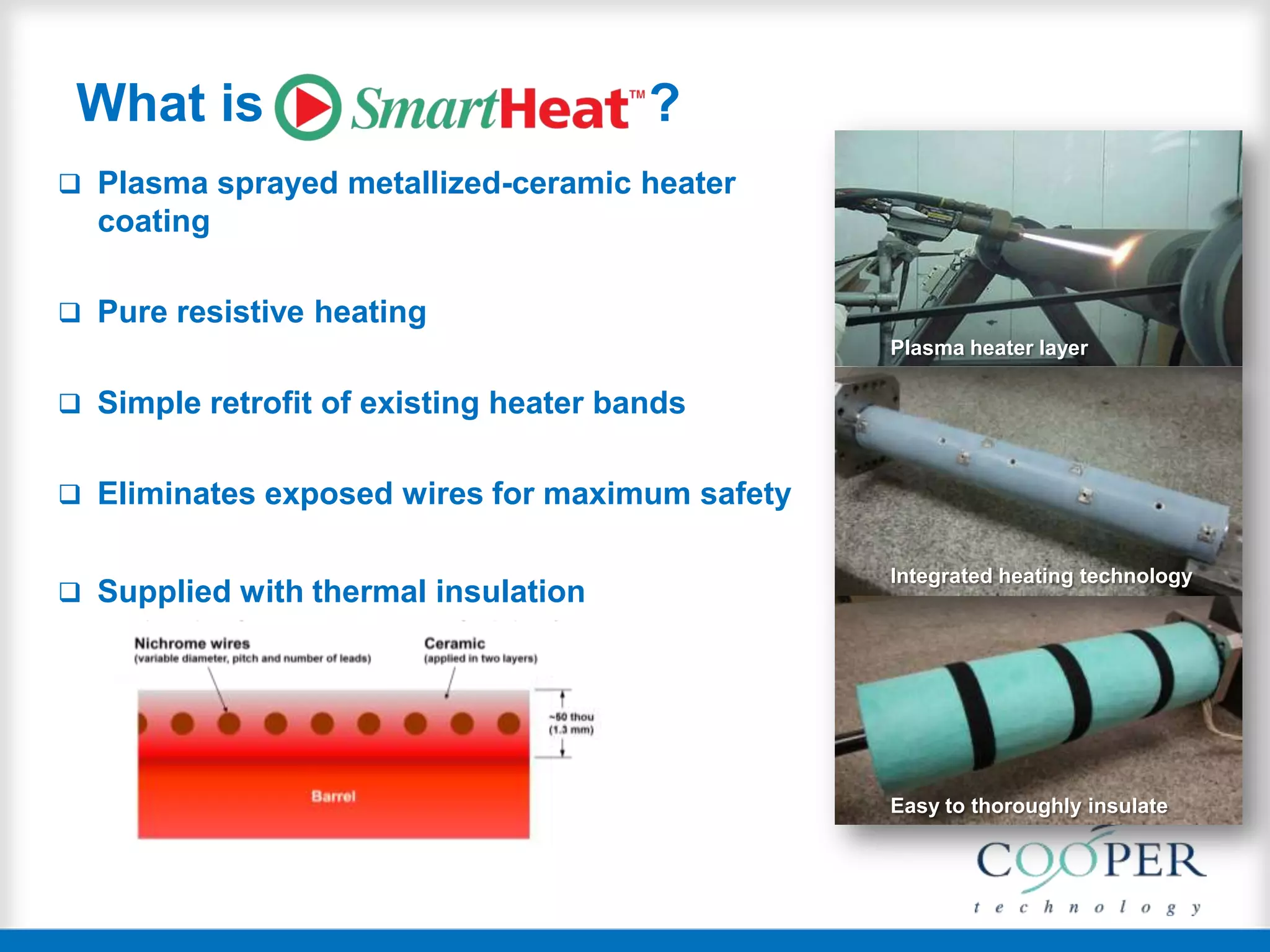

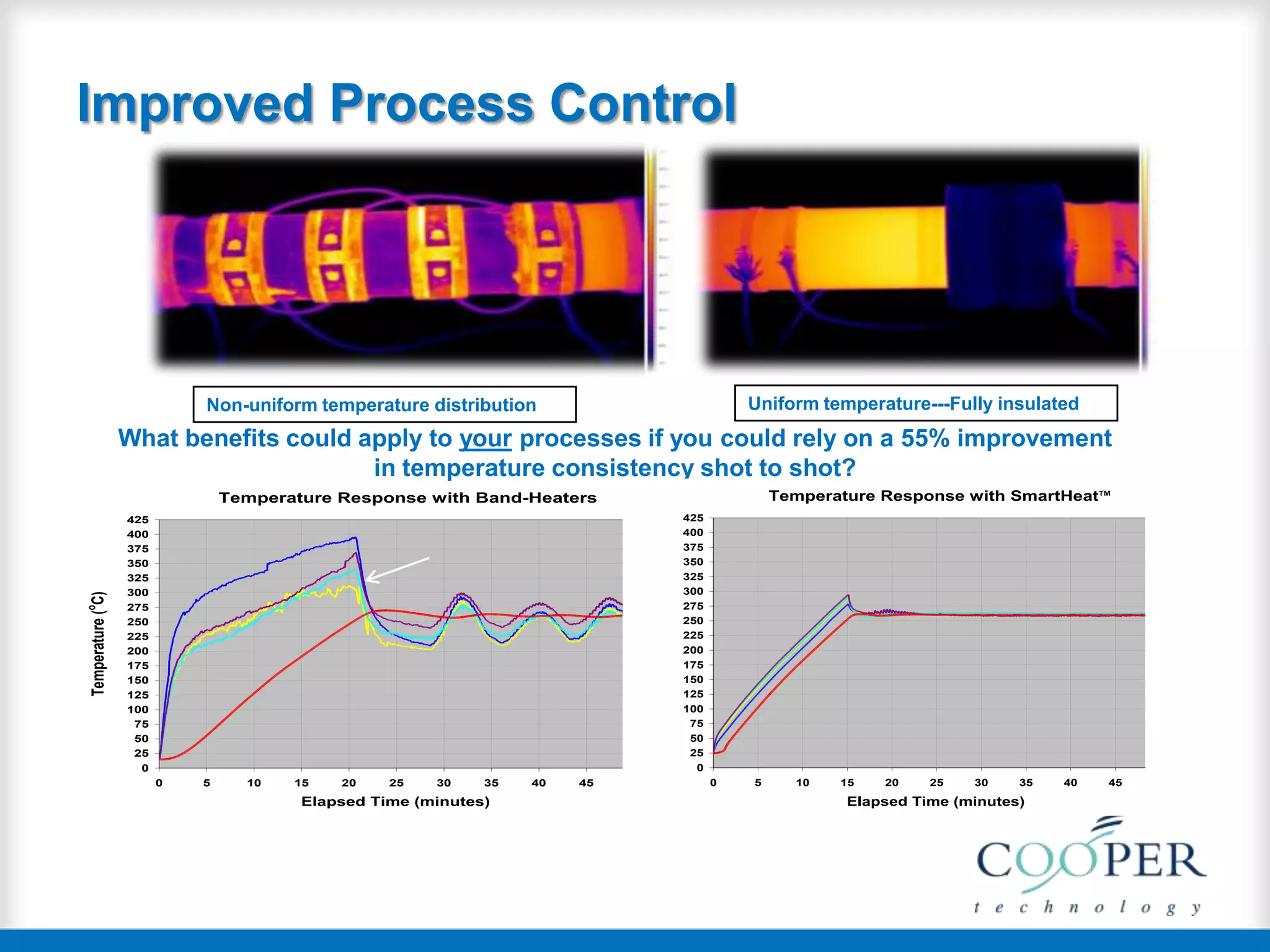

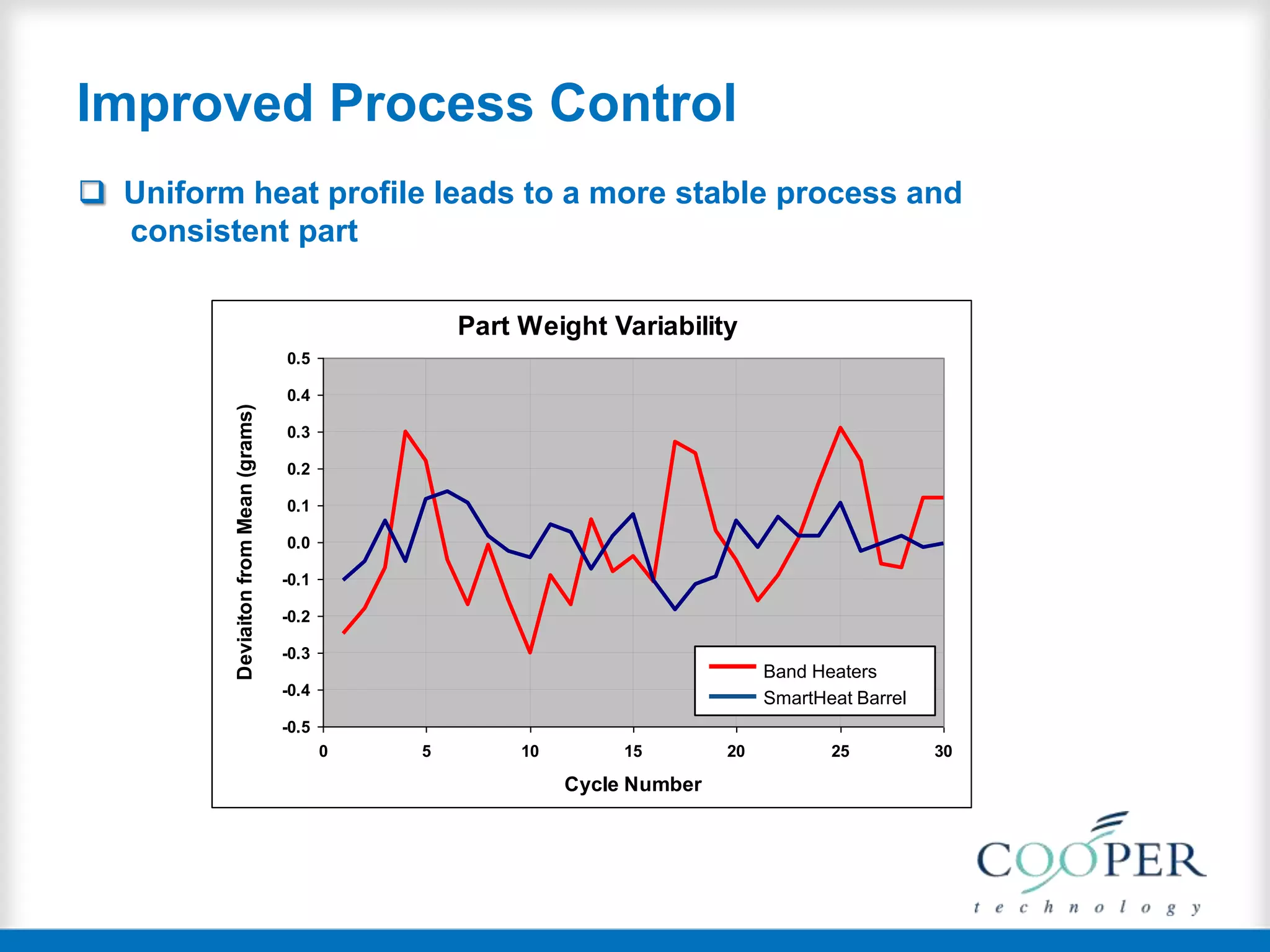

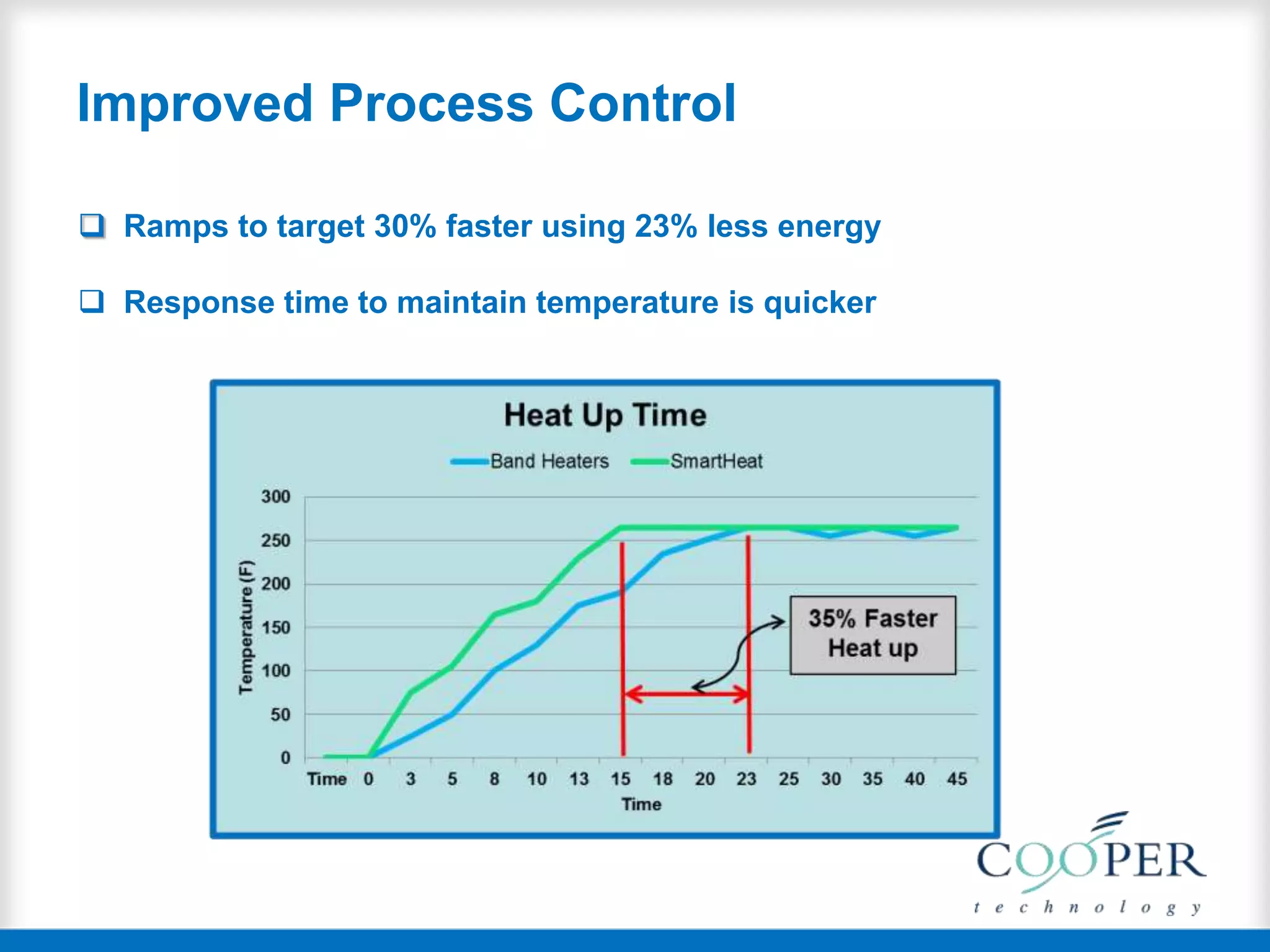

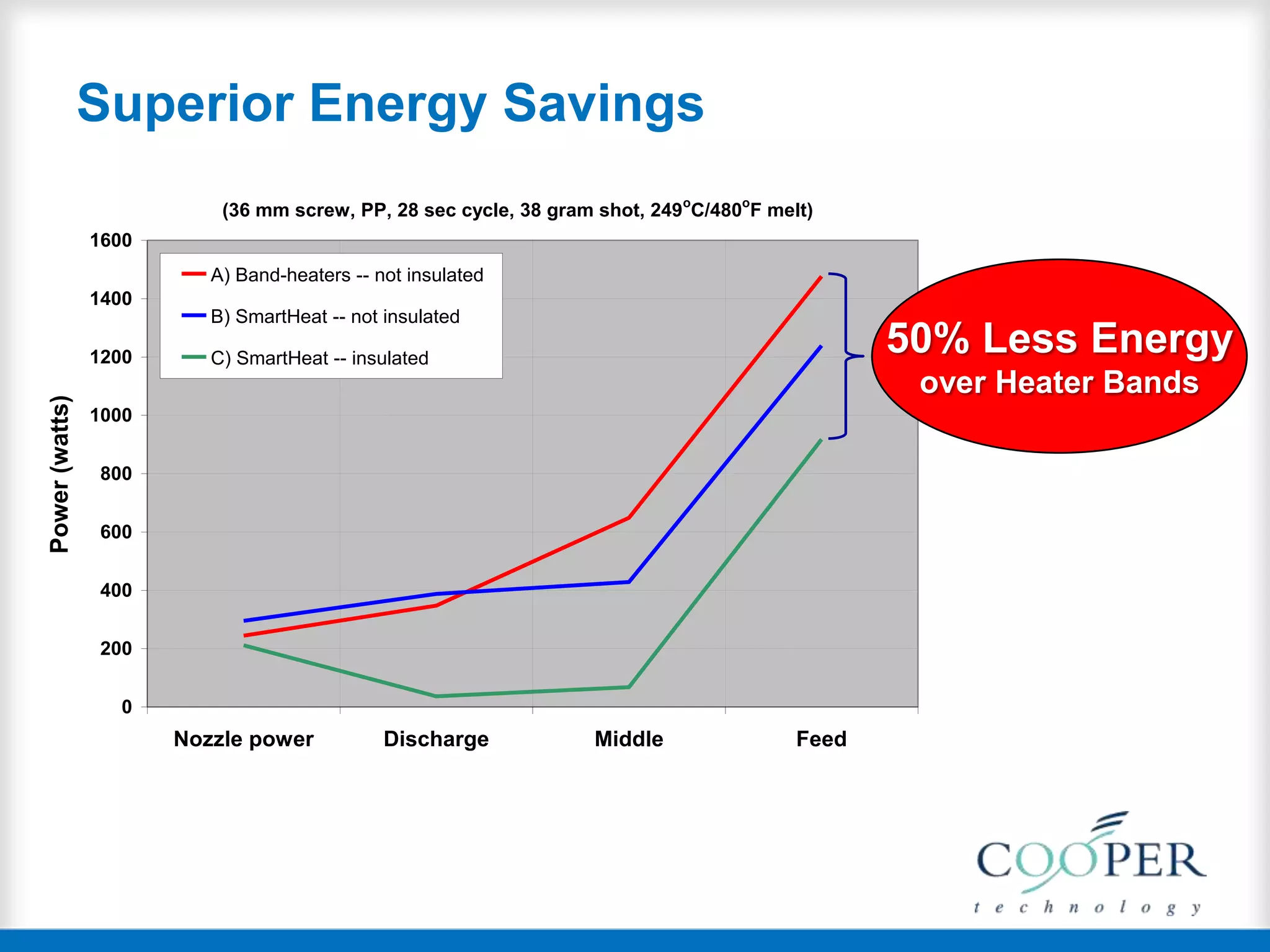

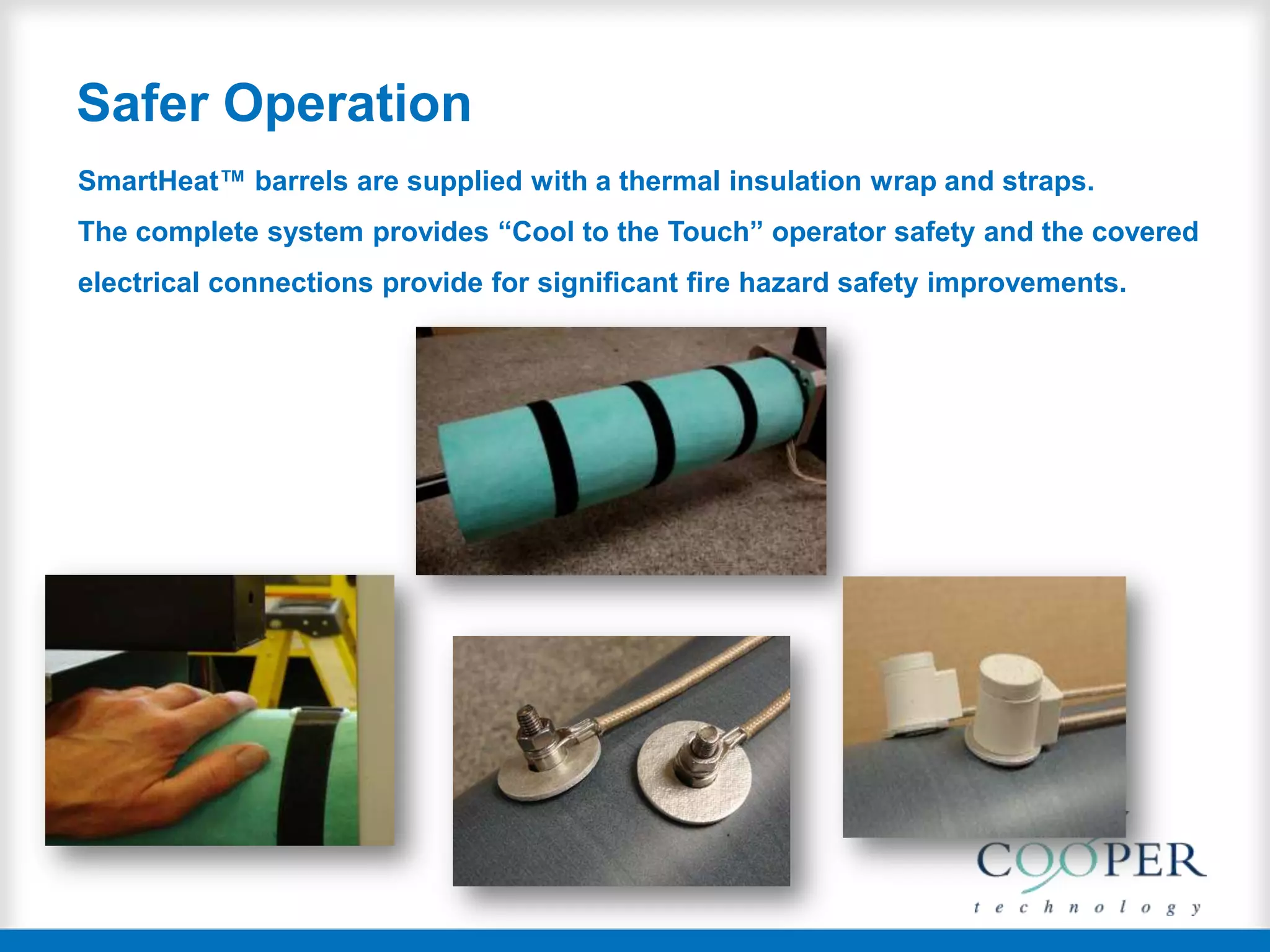

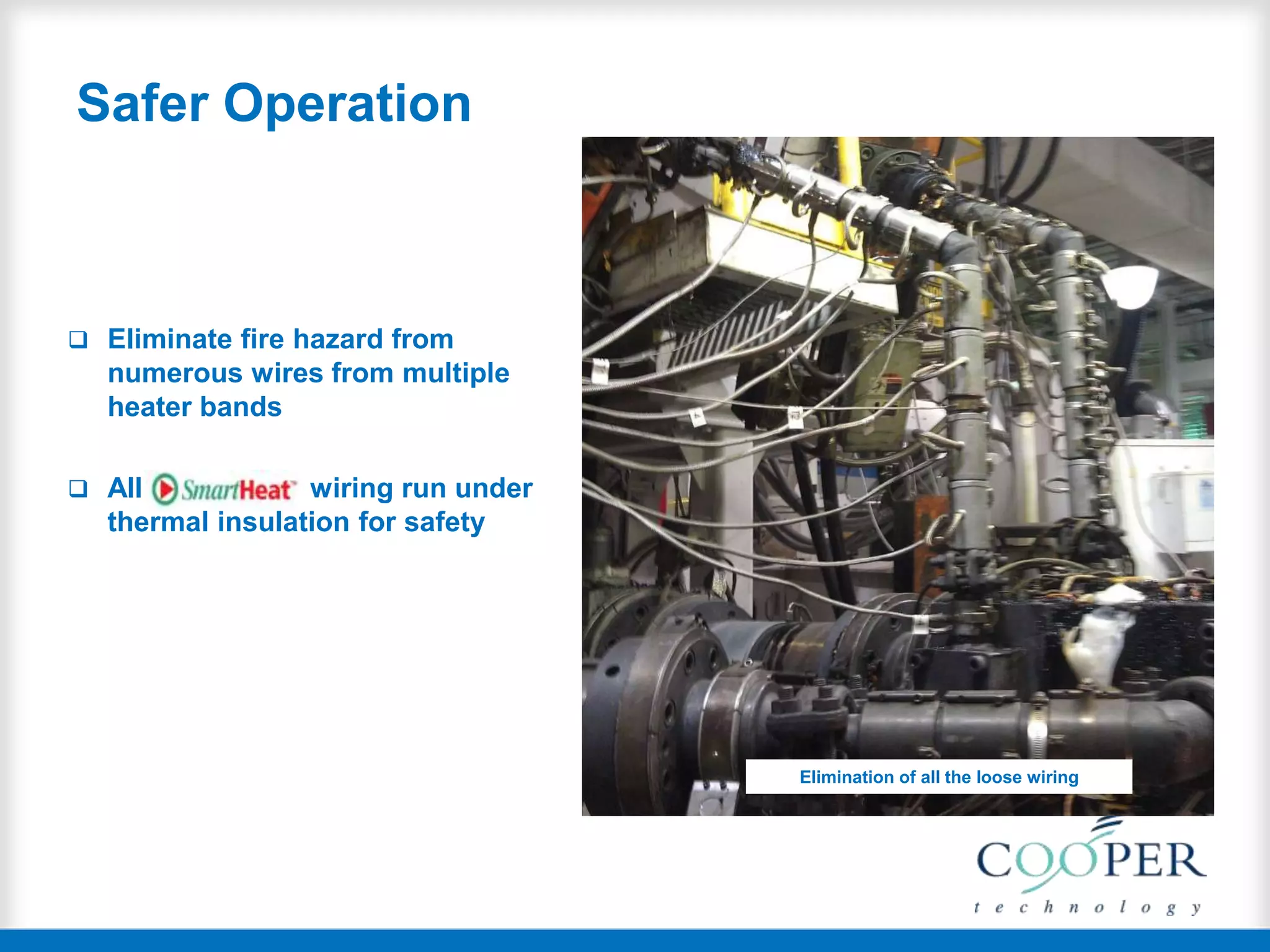

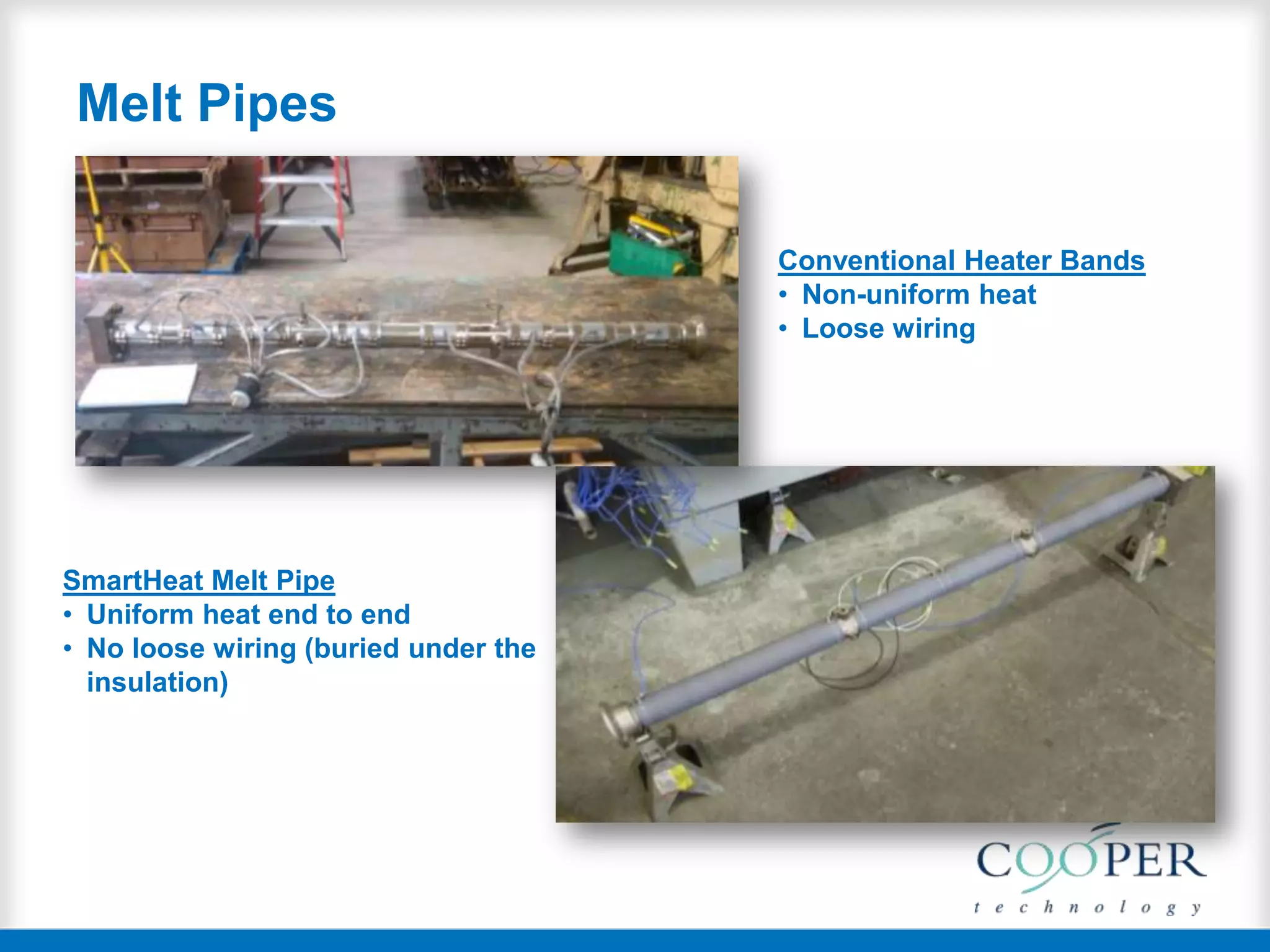

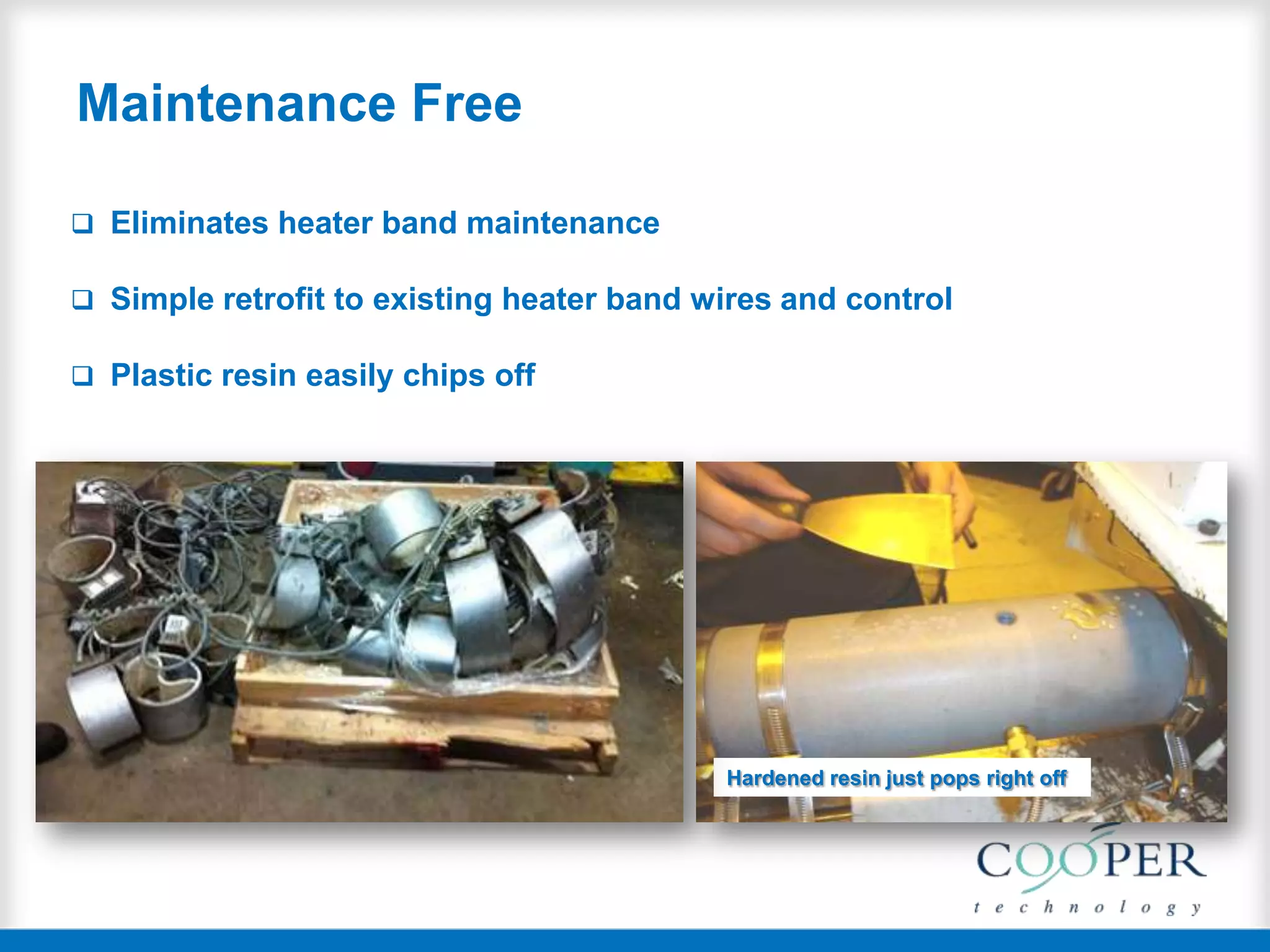

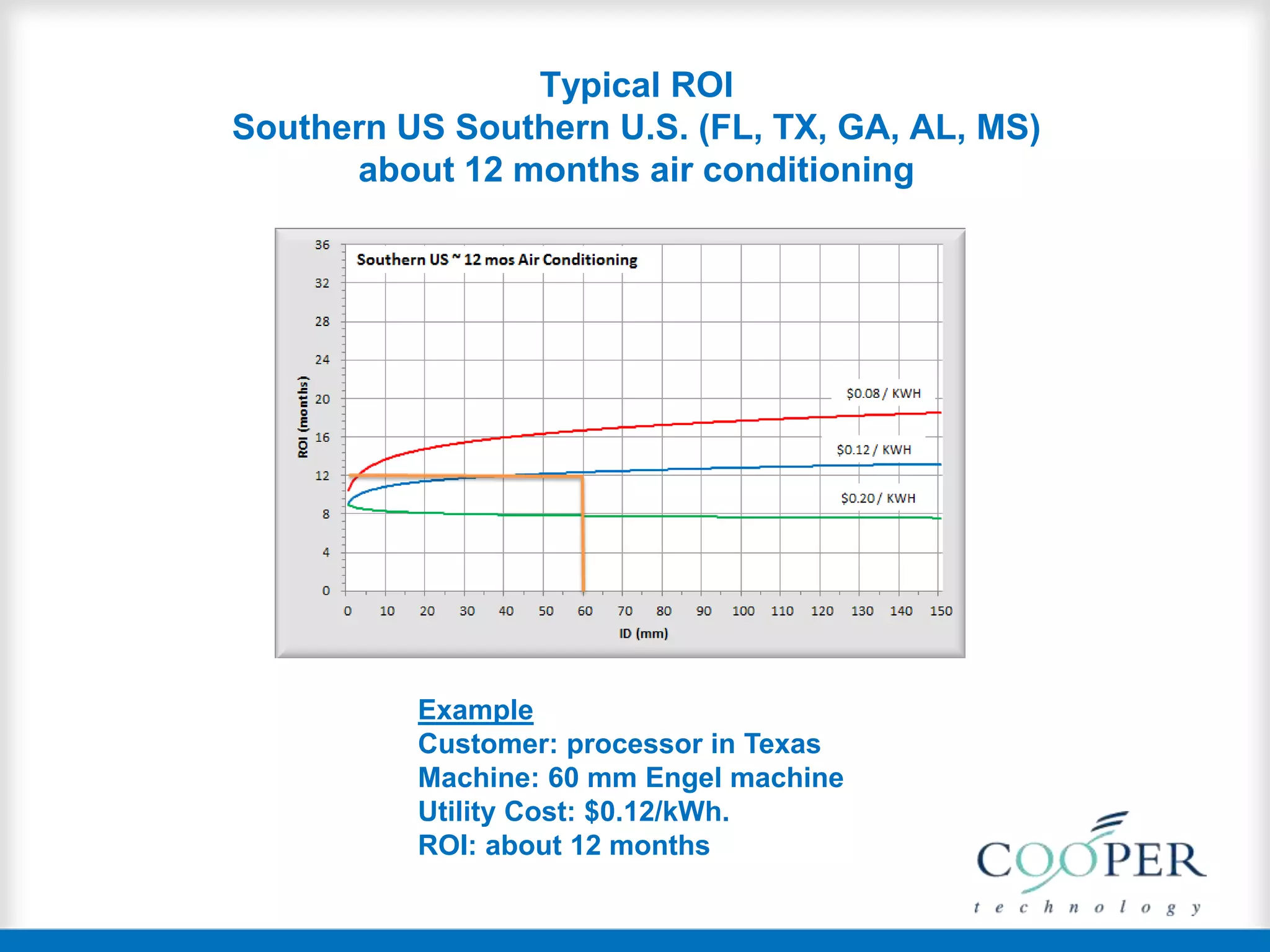

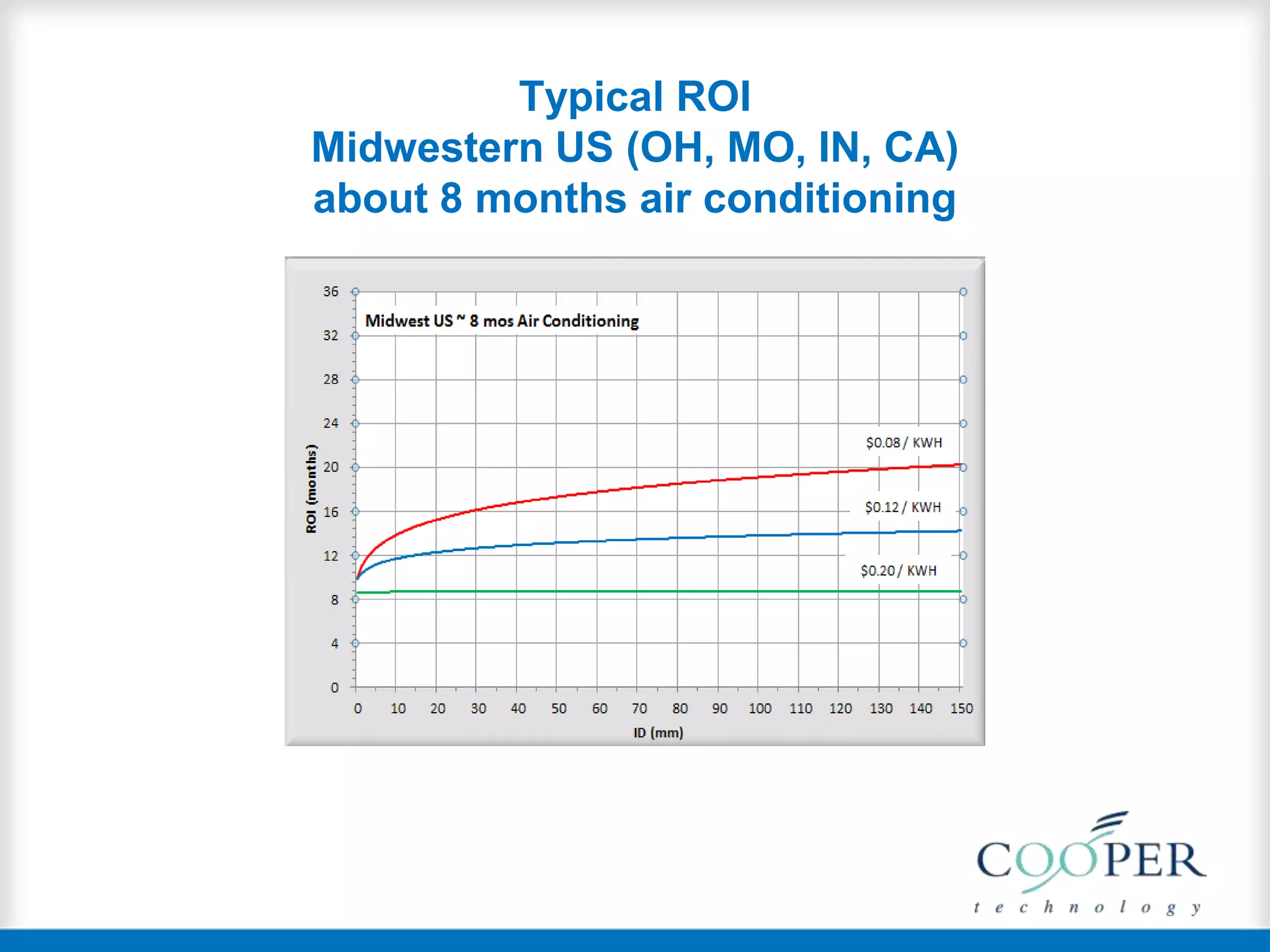

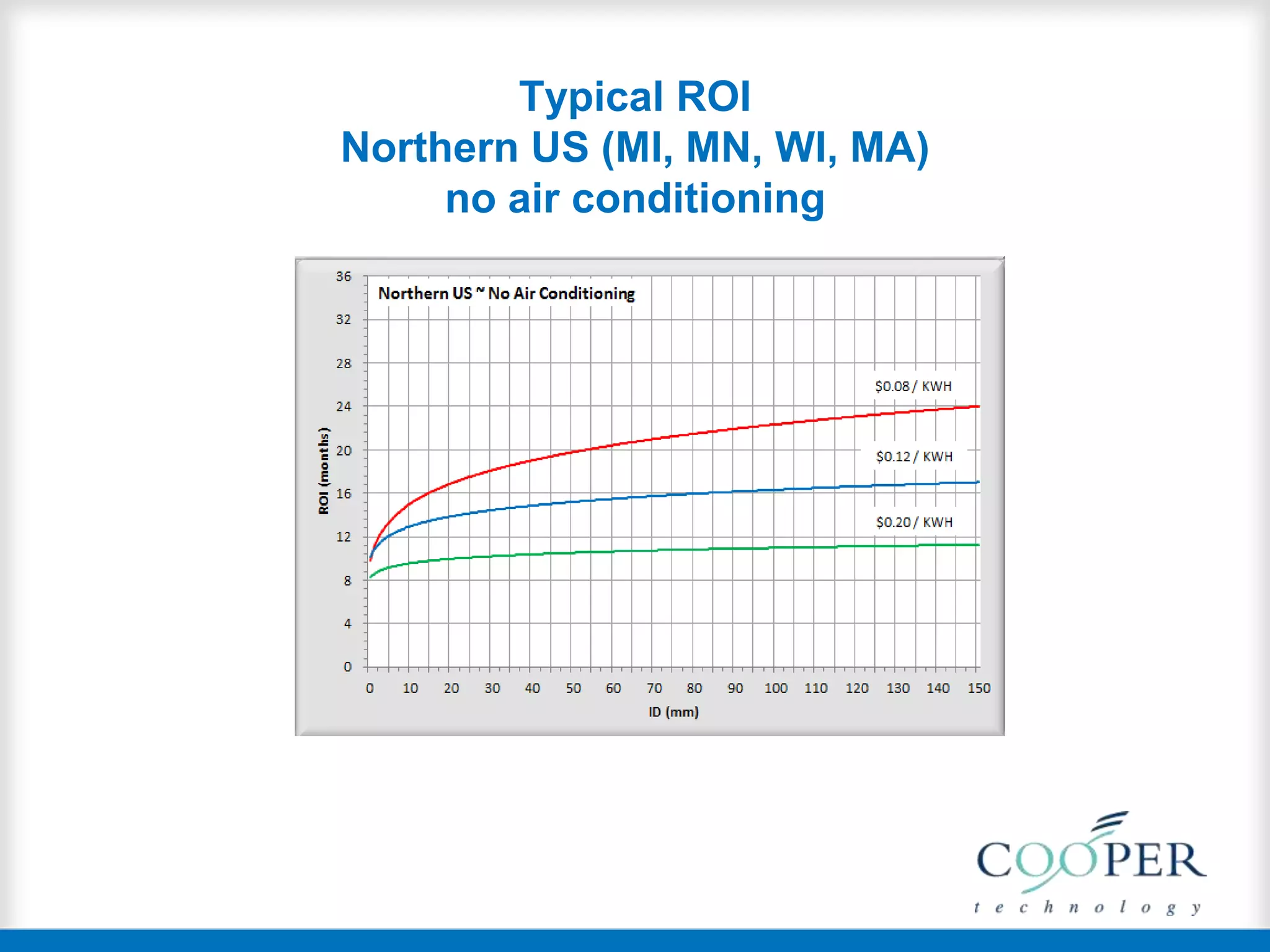

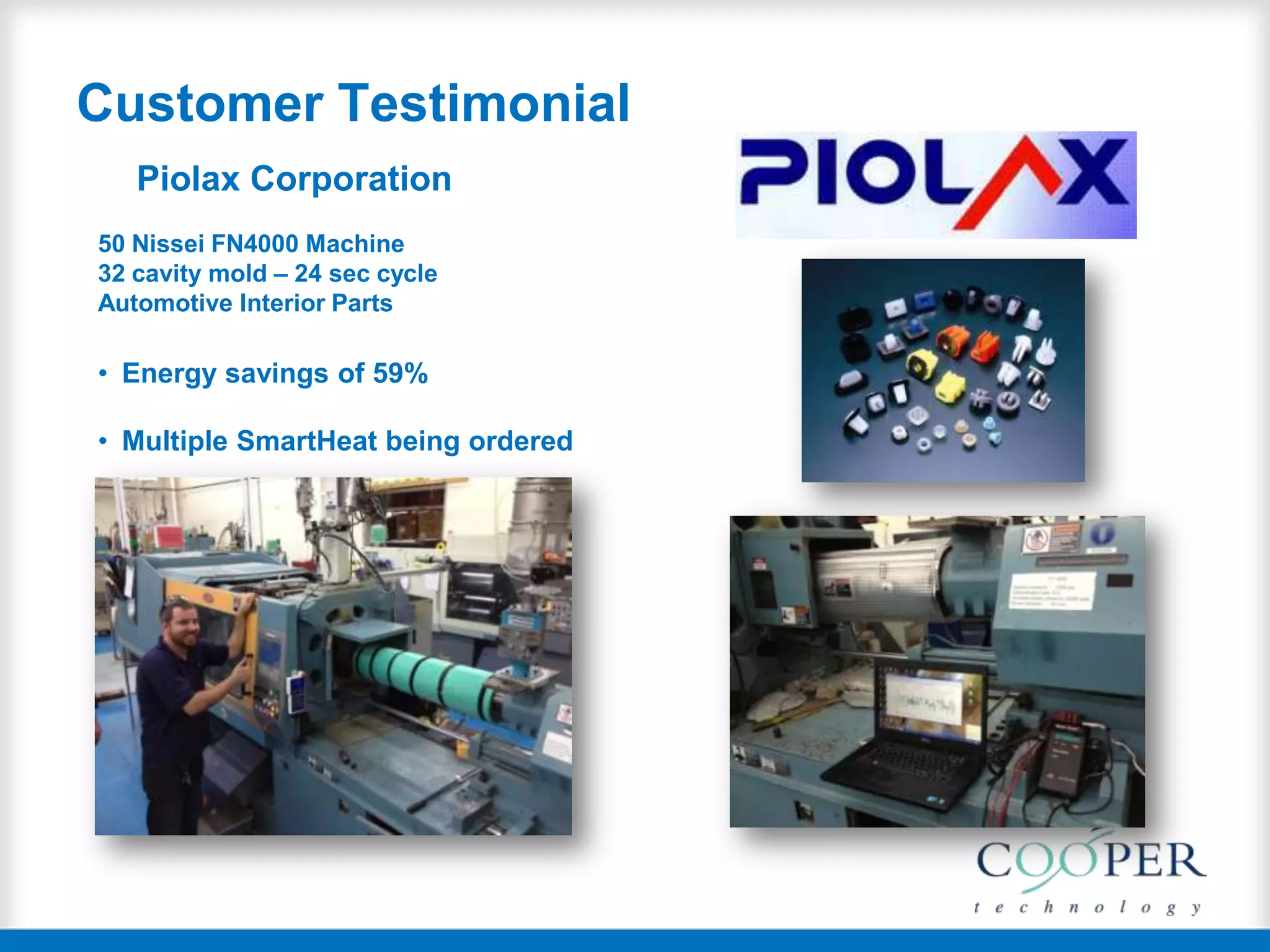

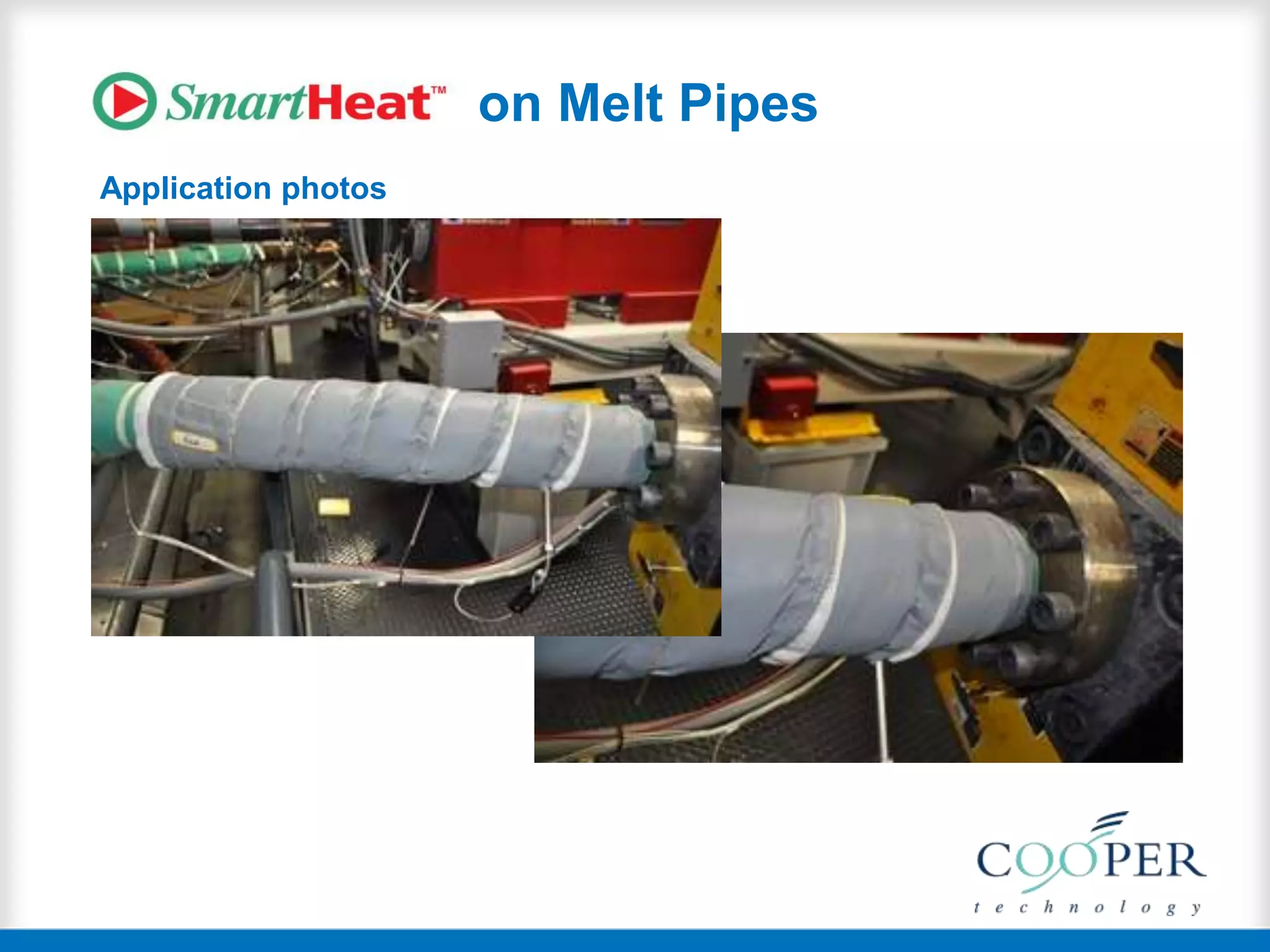

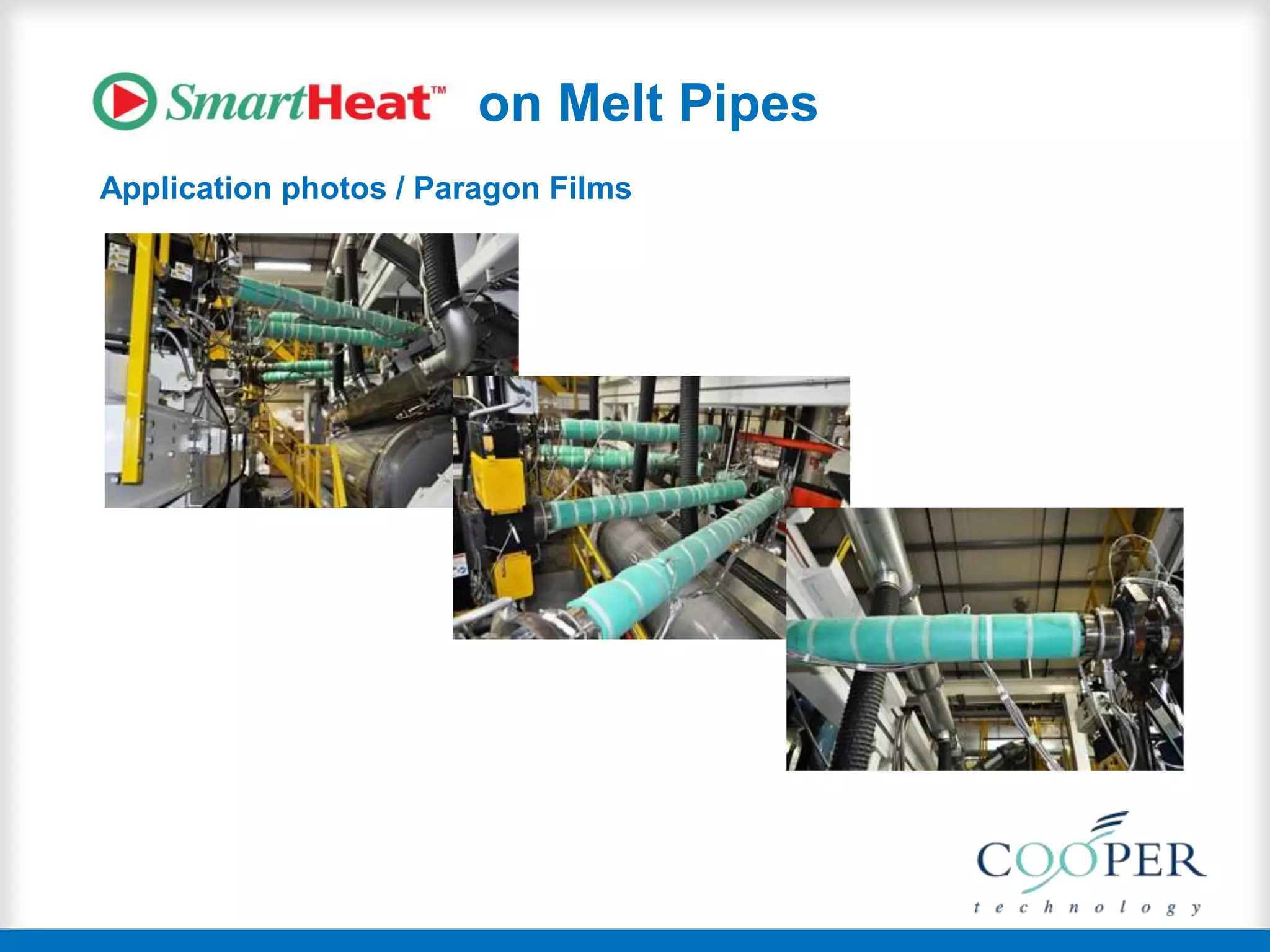

SmartHeat is a new integrated barrel heating technology that offers improved process control, superior energy savings, and safer operation compared to traditional band heaters. It provides a uniform temperature profile for more consistent shots and reduces scrap. Testing shows it can improve temperature consistency by 55% and reduce energy usage by 30-60%. The plasma sprayed ceramic coating is maintenance-free and eliminates fire hazards from exposed wiring. Customers report paybacks of less than one year from reduced energy costs and improved productivity.