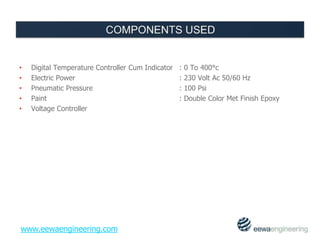

Eewa Engineering has over 45 years of experience developing custom machinery. They designed and marketed their line of heat sealing machines for testing flexible films in India. Their lab 150 and lab 600 models accommodate both impulse and direct heat sealing. The machines can analyze the sealability of various plastic films and laminates and consist of controls for temperature, pressure, time and other parameters.