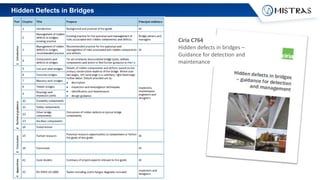

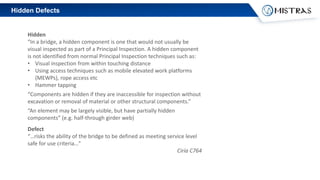

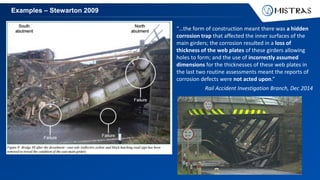

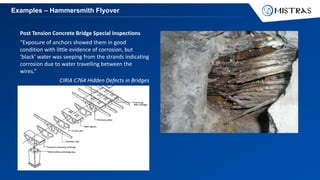

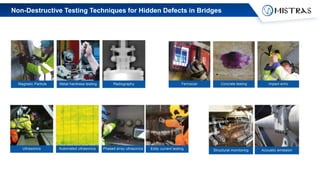

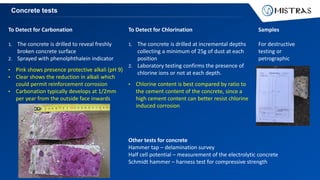

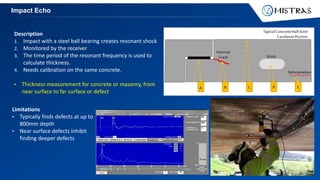

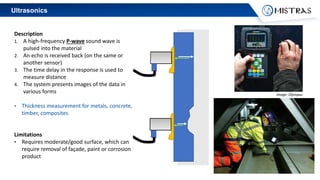

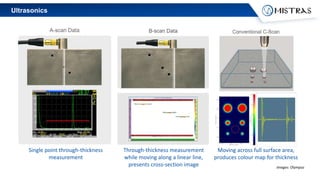

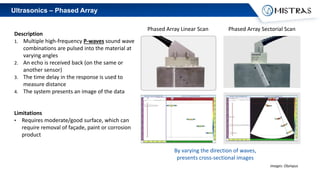

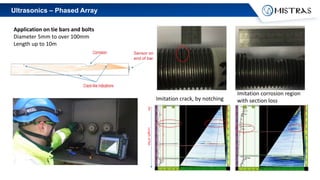

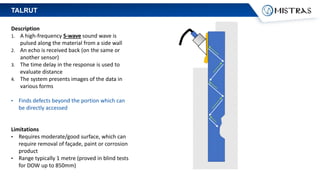

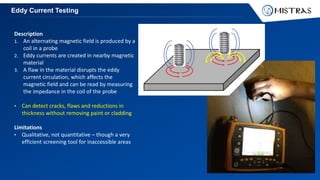

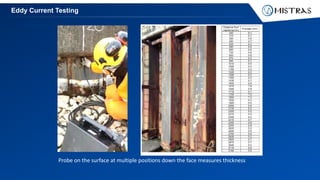

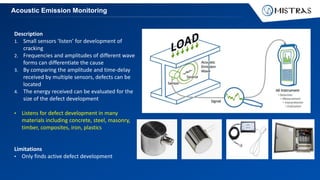

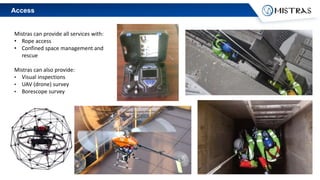

The document discusses hidden defects in bridges, emphasizing the challenges in detecting critical elements that are not visible during standard inspections. It highlights various non-destructive testing techniques and their limitations in identifying hidden defects and ensuring structural integrity. Recommendations are provided for effective inspections and considerations for selecting appropriate investigative methods.