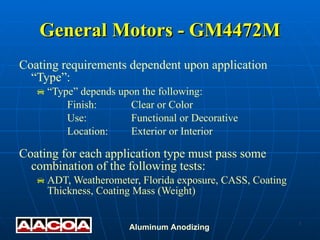

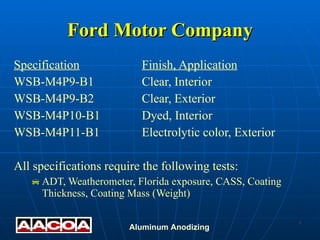

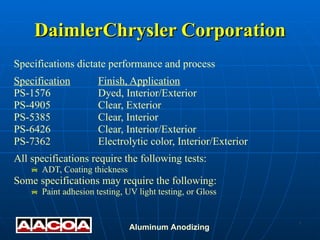

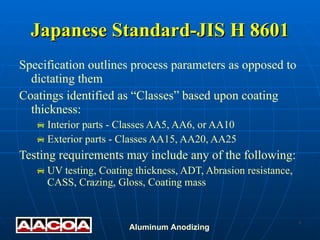

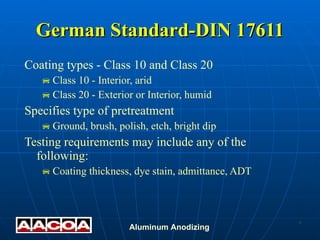

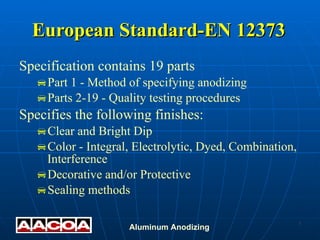

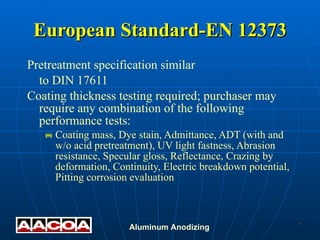

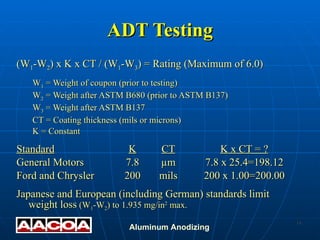

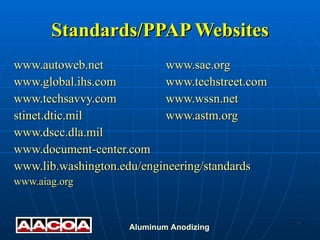

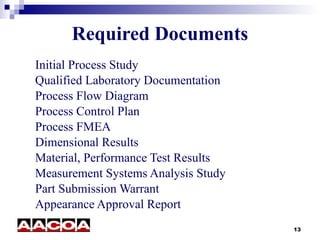

The document summarizes automotive specifications for aluminum anodizing from various standards organizations. It outlines the general requirements for General Motors, Ford, DaimlerChrysler, Japanese, German, and European standards. All require various testing such as adhesion, thickness, and corrosion resistance testing. It also provides information on documentation required for the Production Part Approval Process (PPAP) such as process studies, control plans, and measurement analysis.