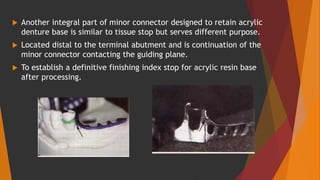

Minor connectors connect components like clasps, retainers, and denture bases to the major connector. They transmit stresses evenly to avoid concentrating loads. There are four types: those connecting clasps, indirect retainers, denture bases, or serving as approach arms for bar-type clasps. Forms include latticework, meshwork, or beads/wires. Minor connectors should be located in interdental embrasures when possible and conform to the embrasure shape and anatomy.