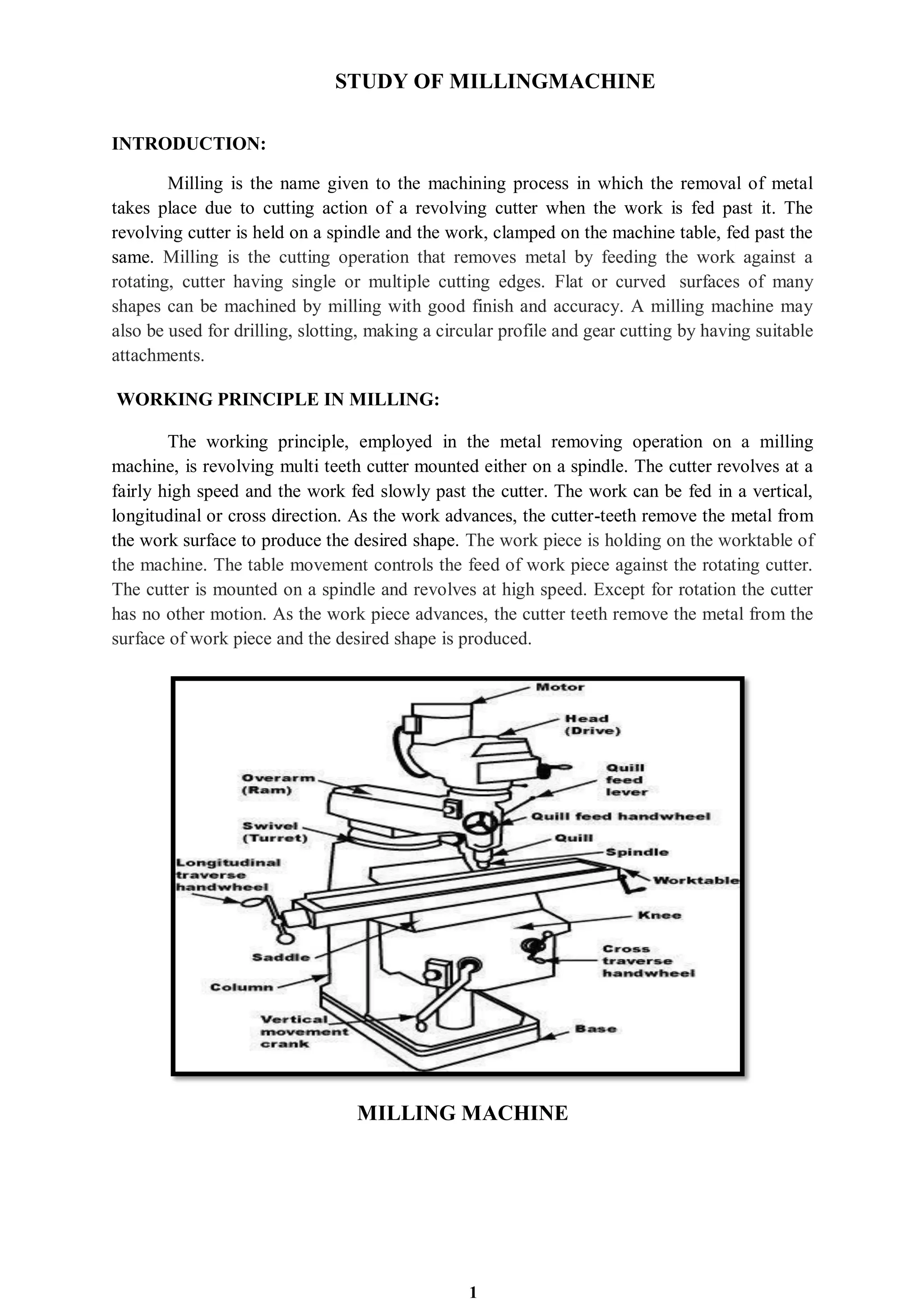

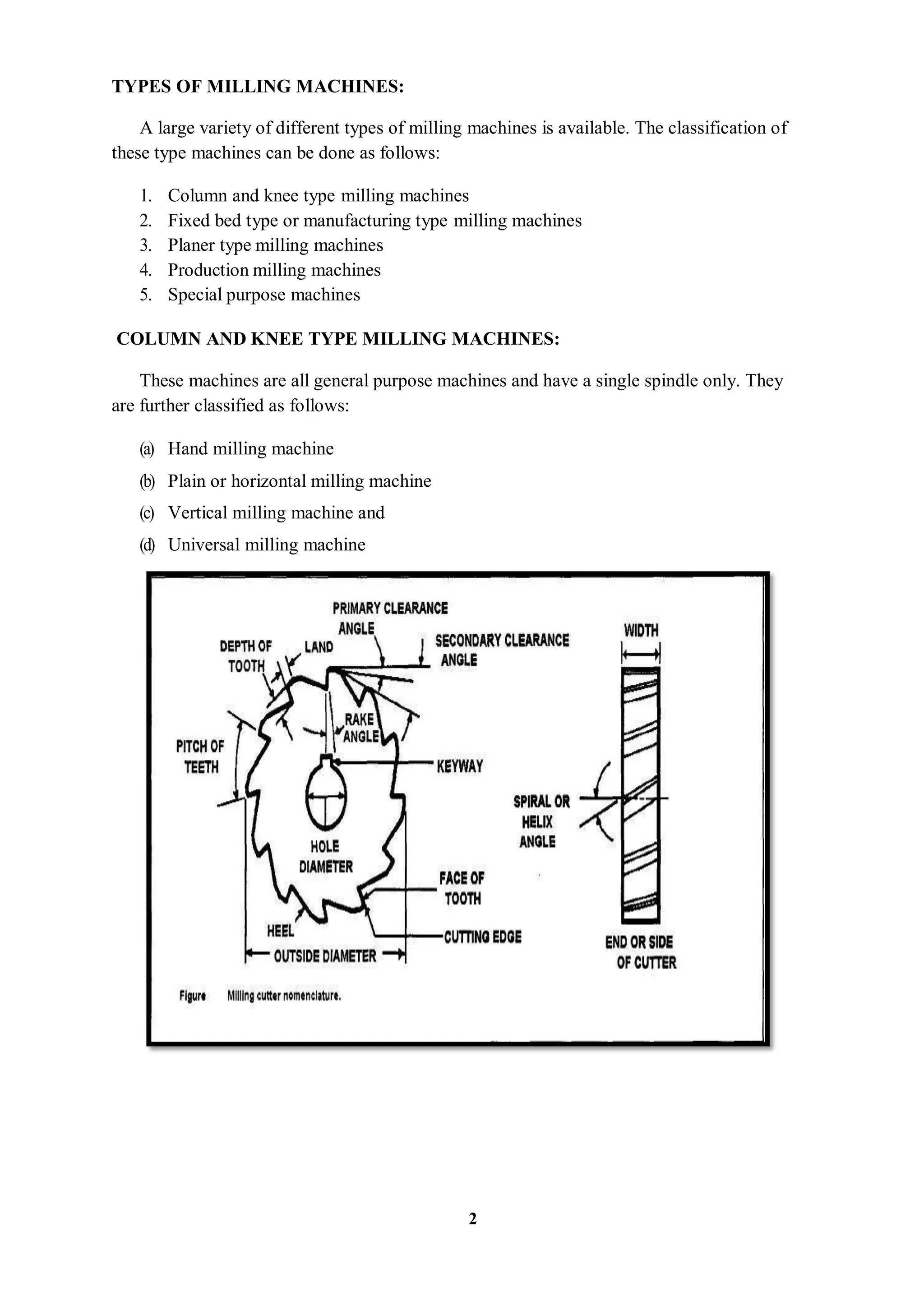

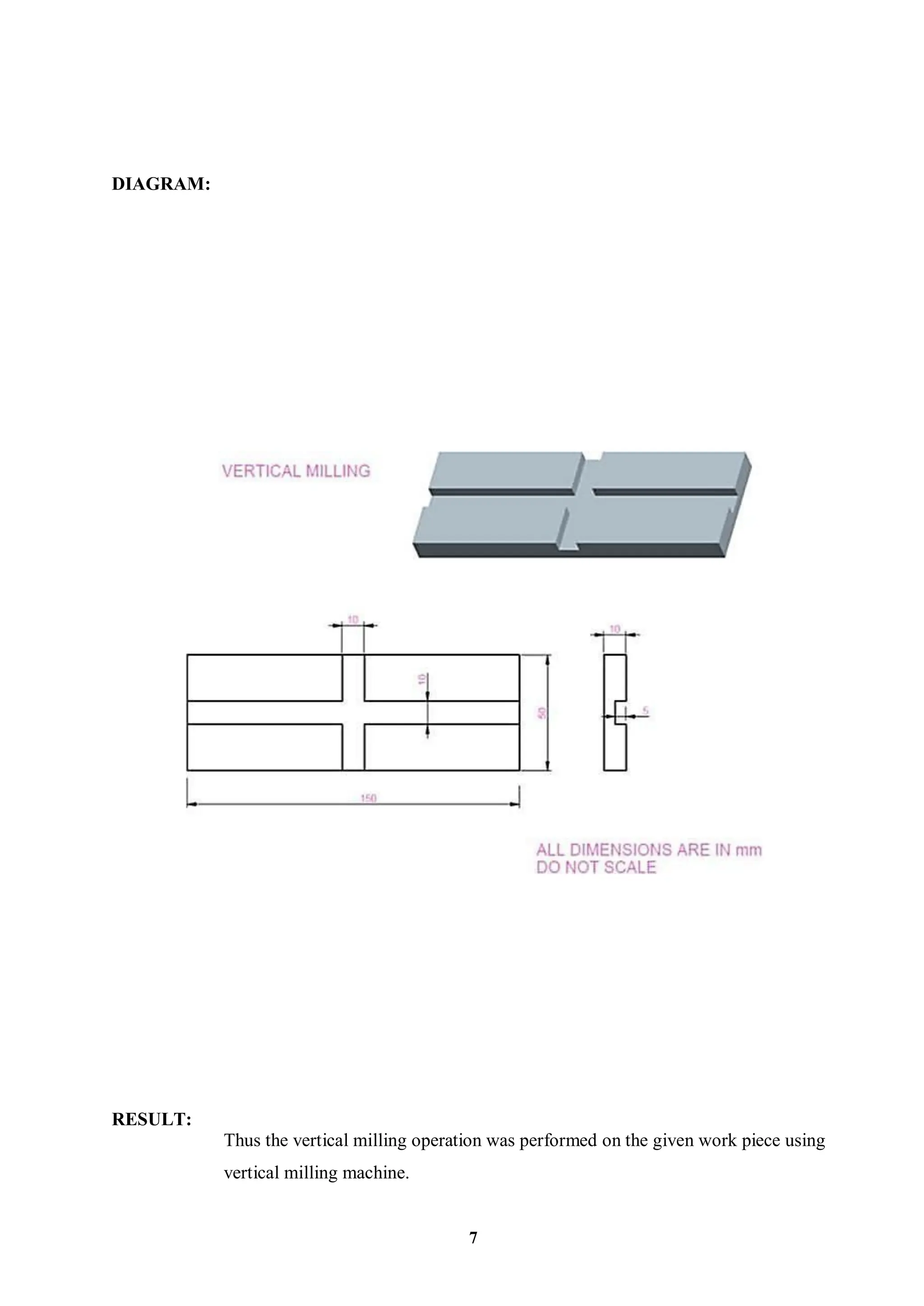

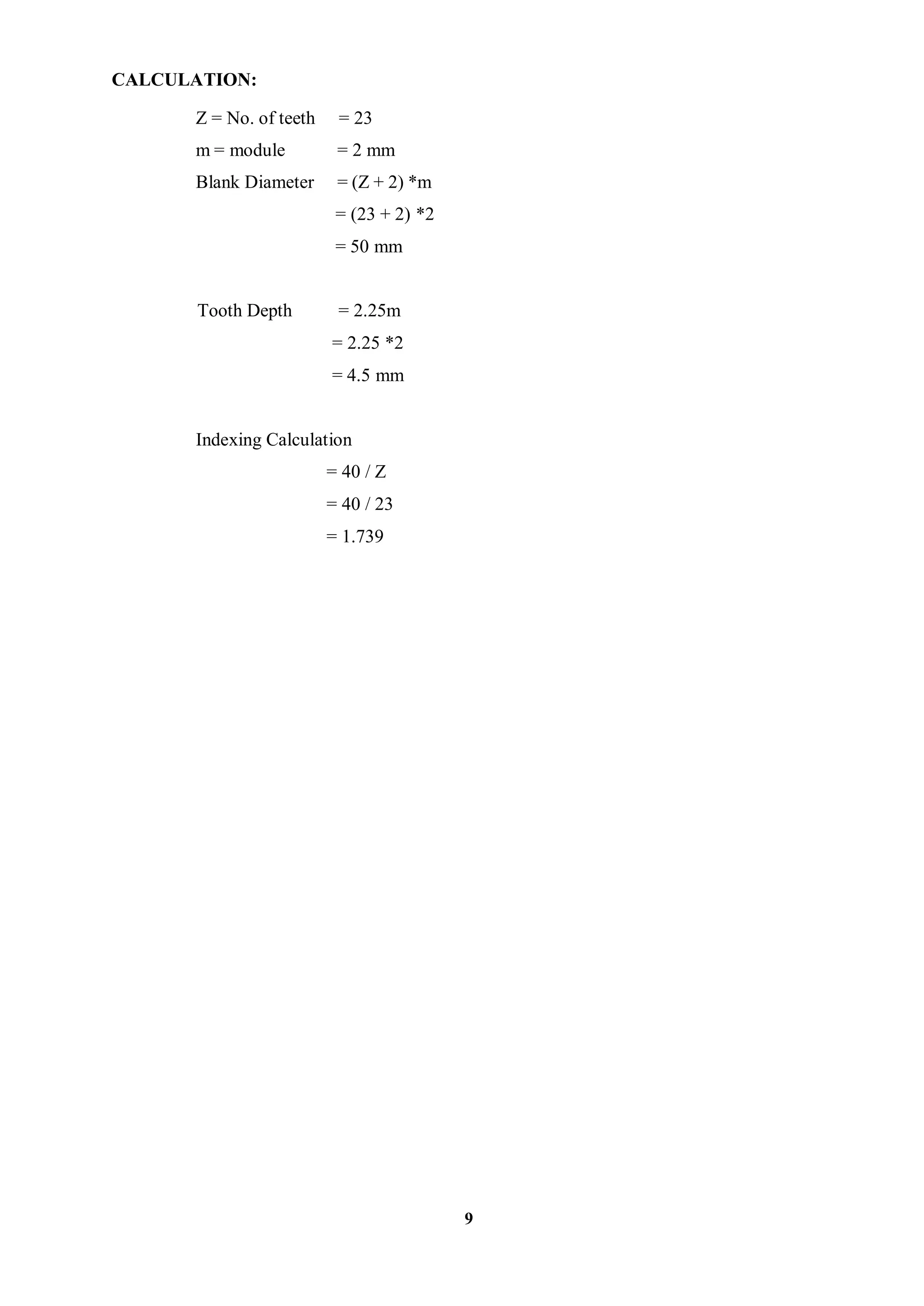

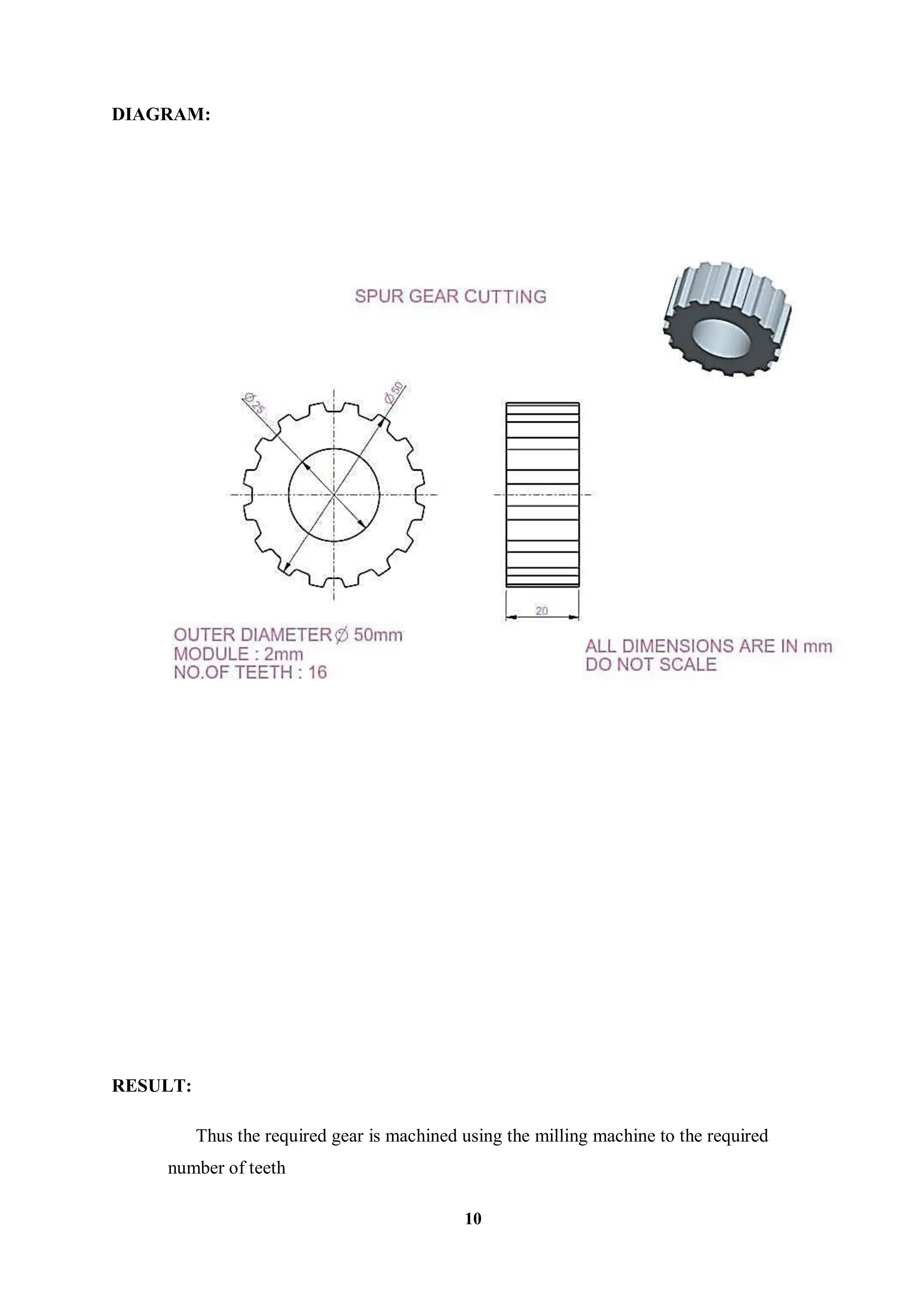

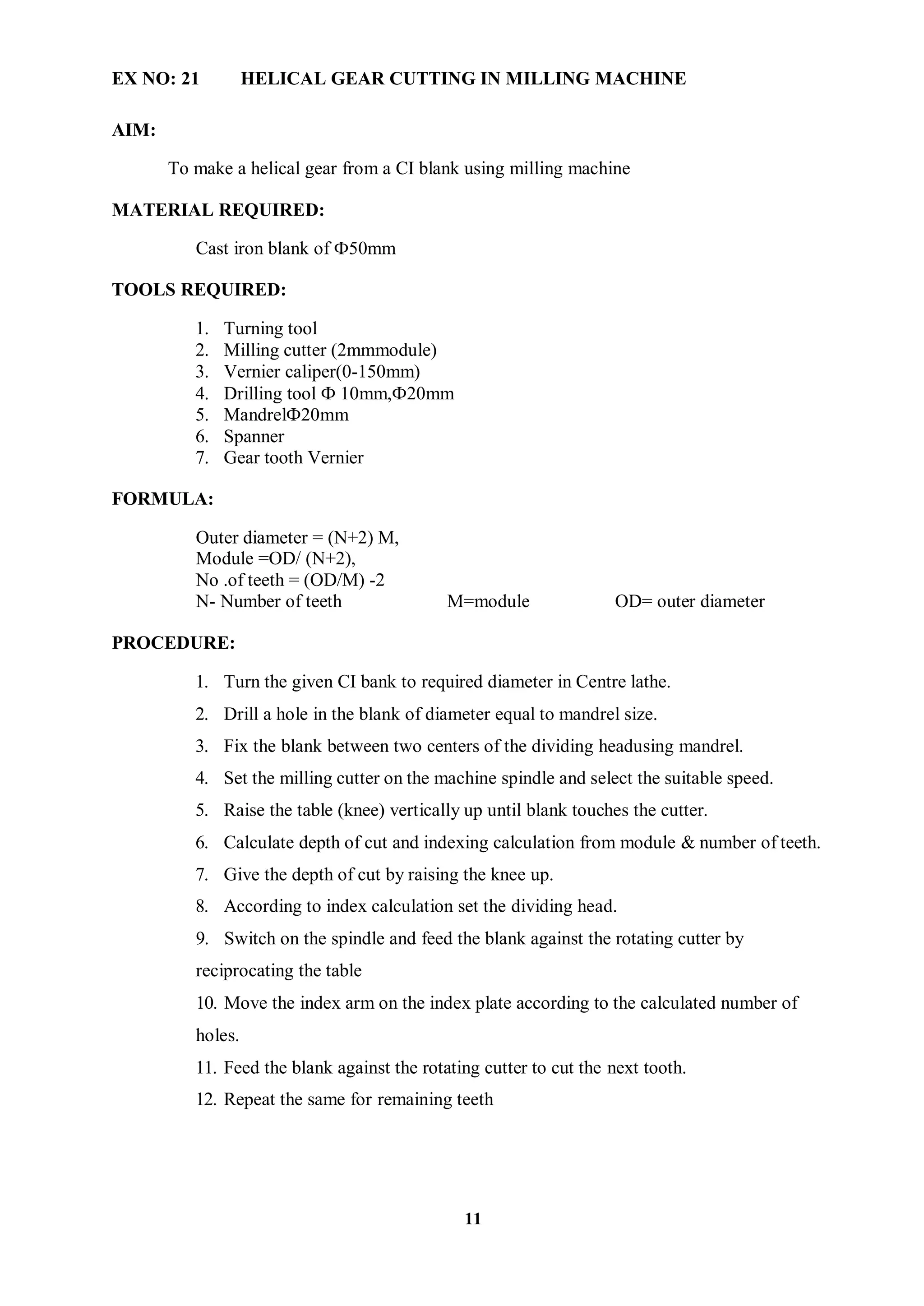

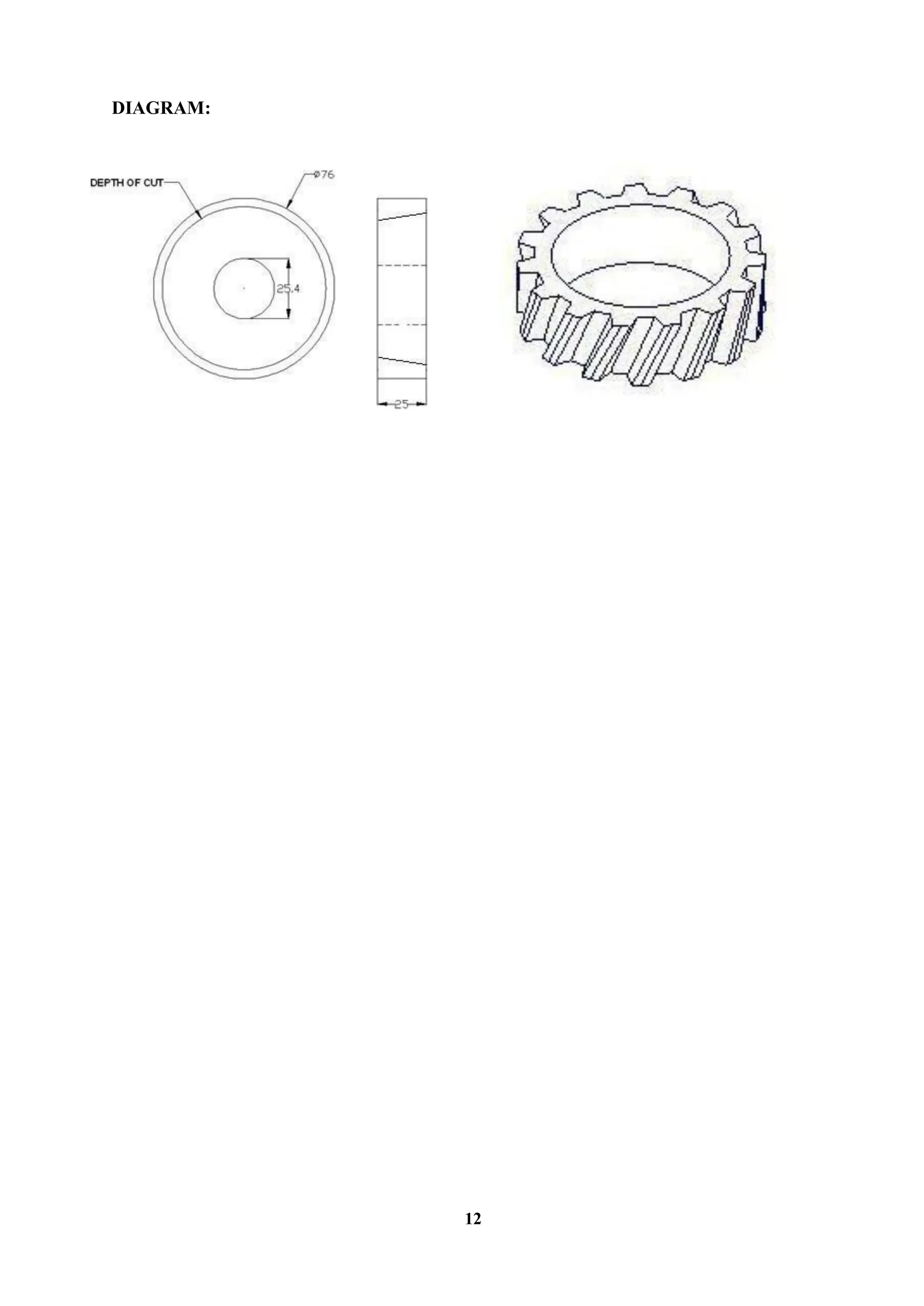

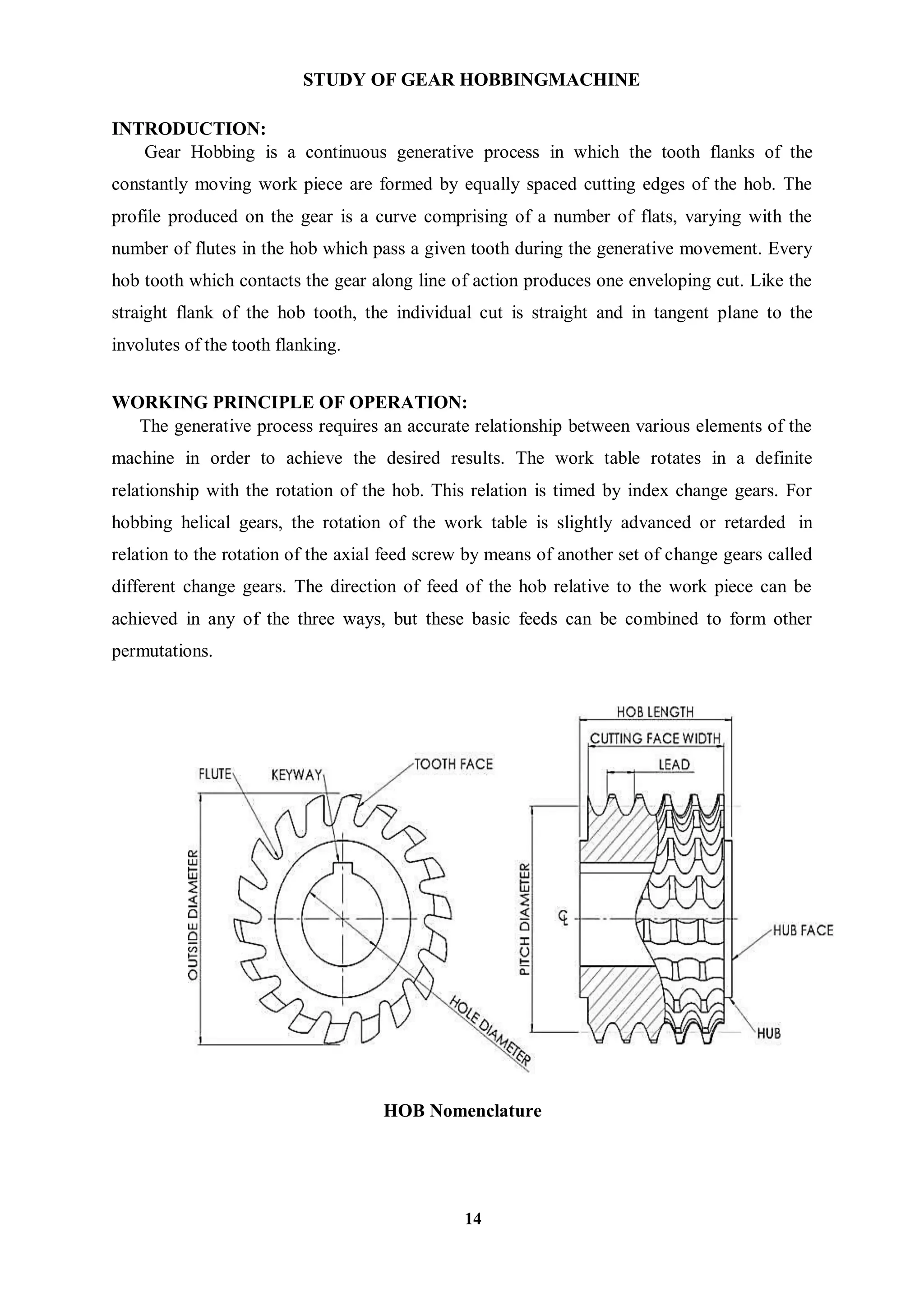

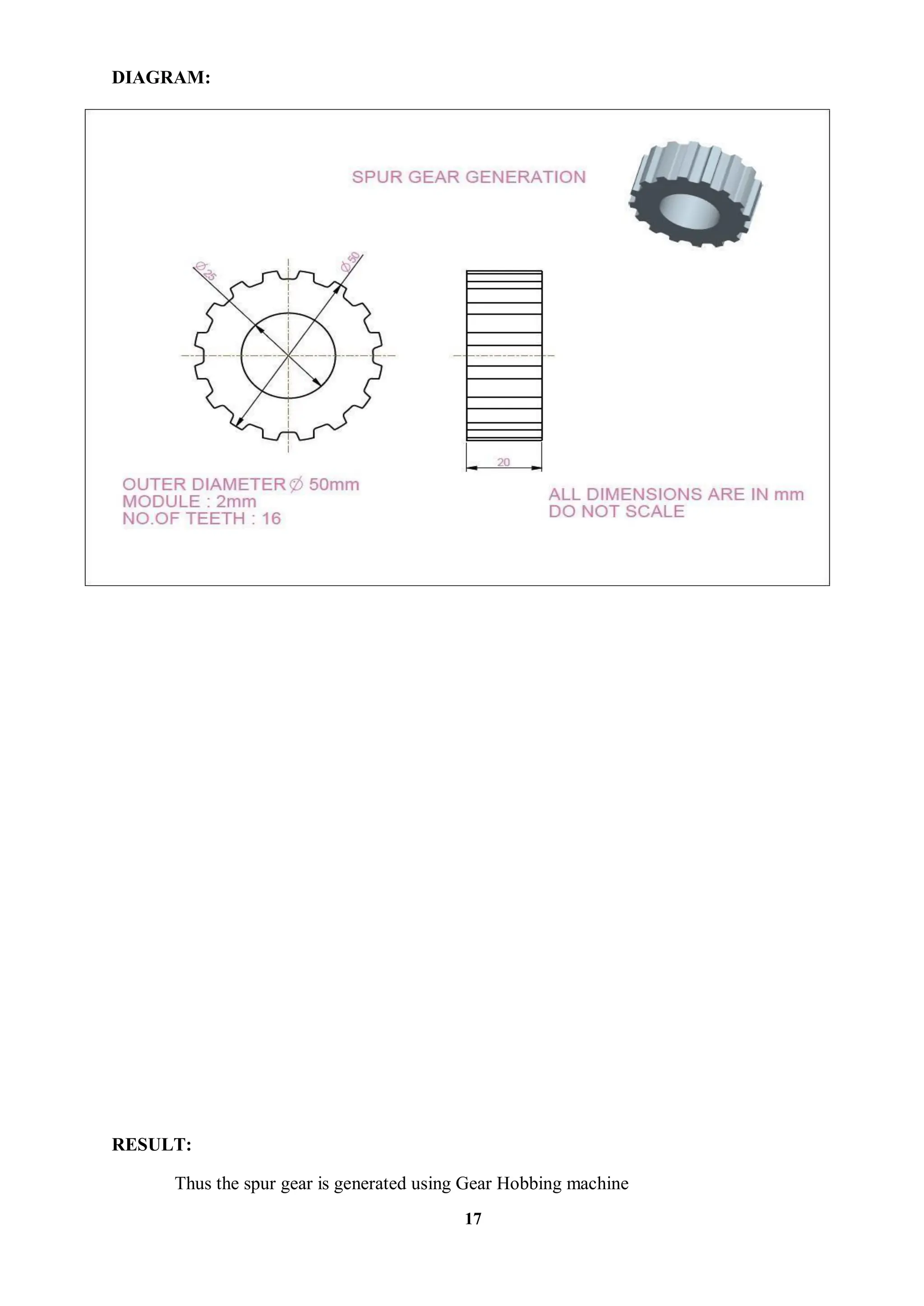

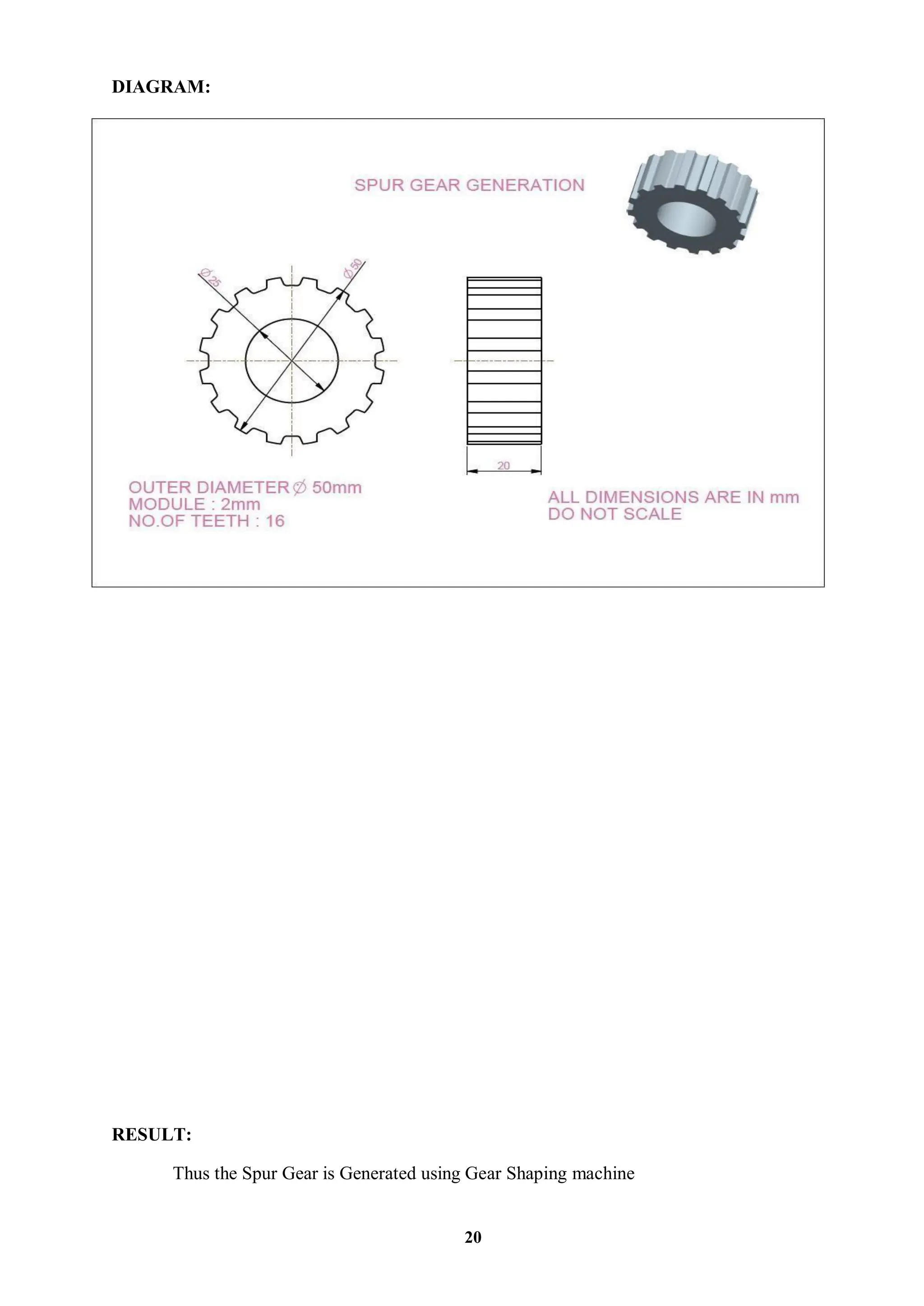

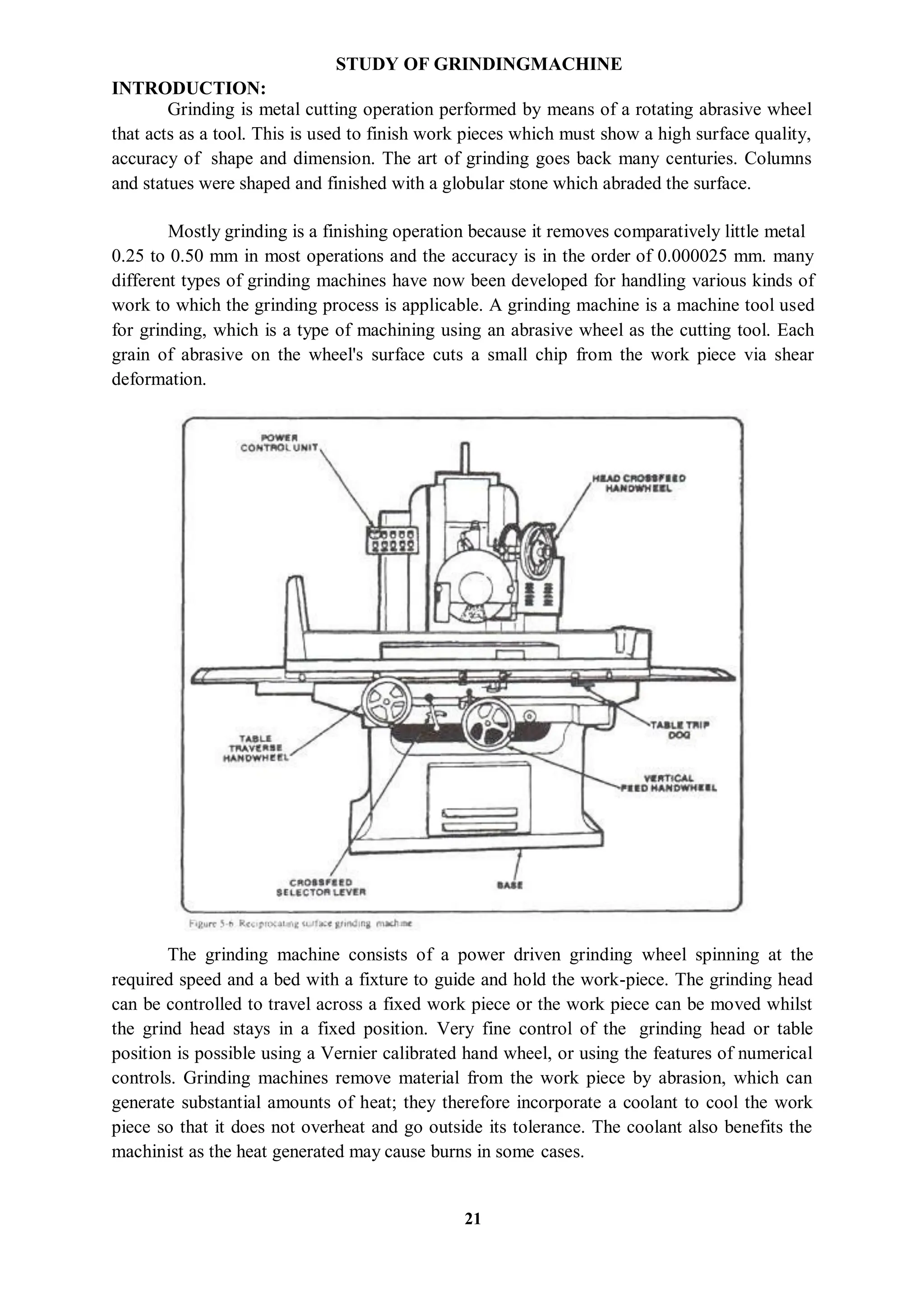

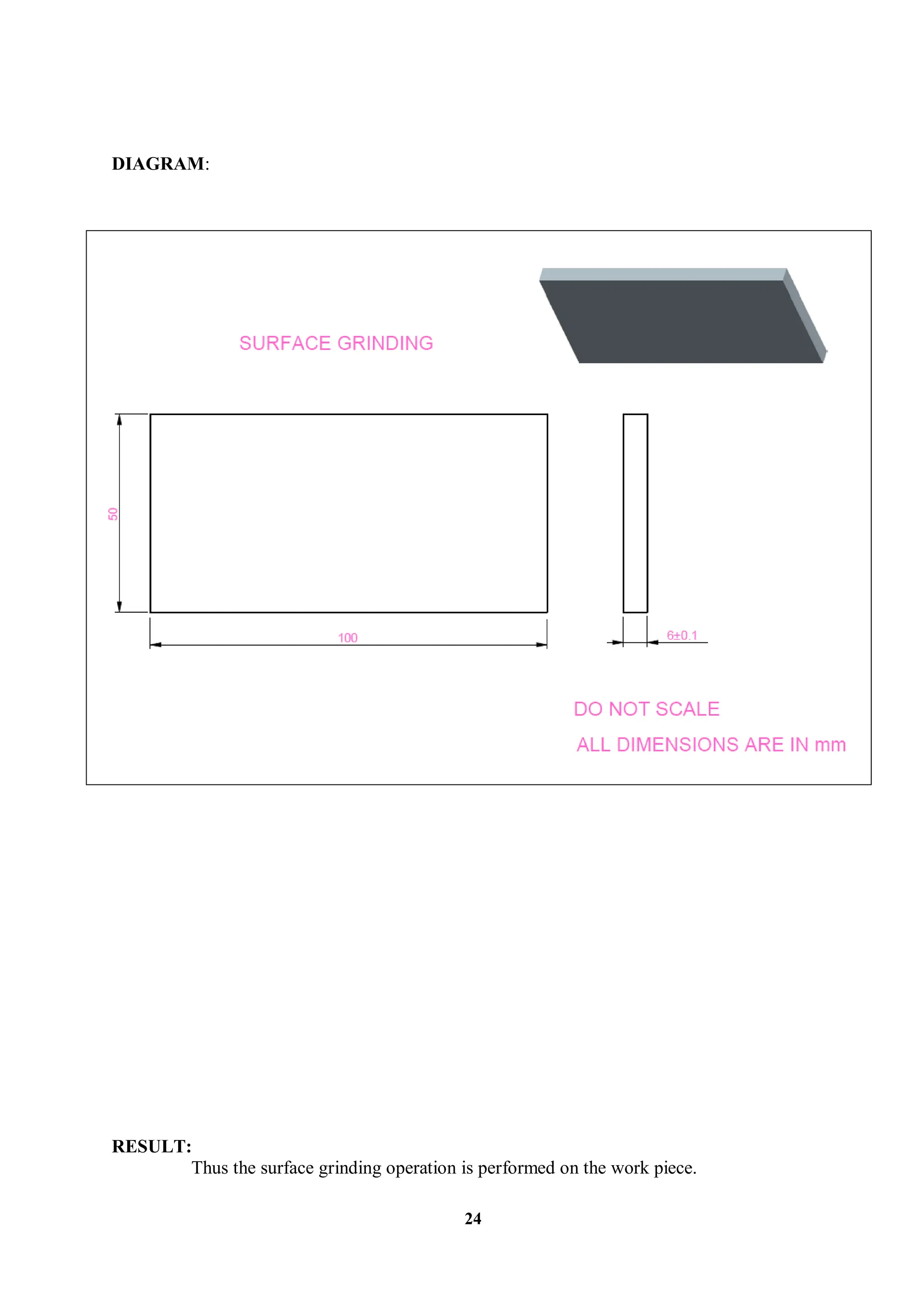

The document provides a detailed overview of milling machines, including their working principles, types, and main components. It outlines various milling operations such as contour milling, spur gear cutting, and helical gear cutting, along with the tools and procedures required for each task. Additionally, the document explains gear hobbing and shaping machines, emphasizing their advantages and operational processes.