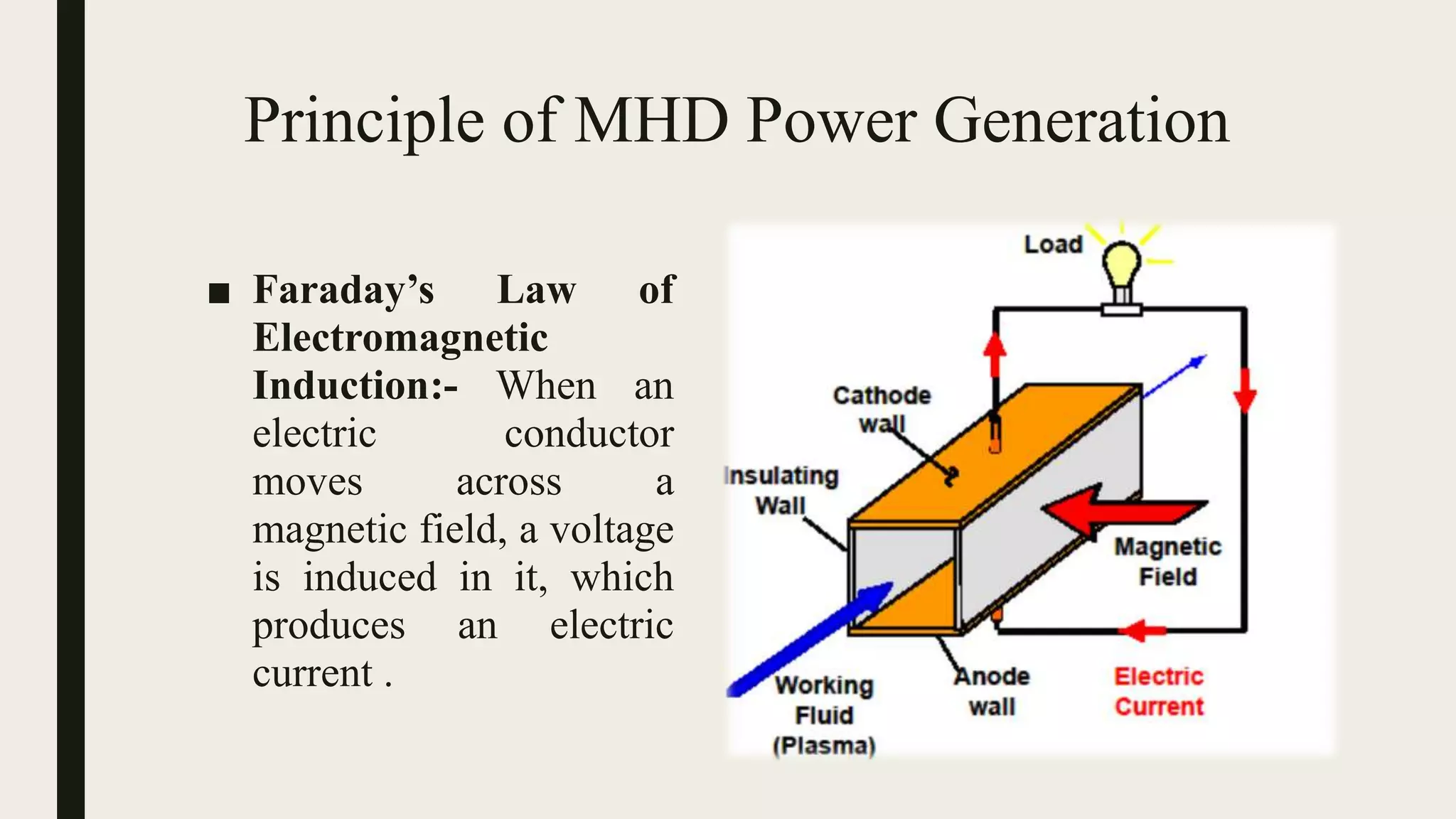

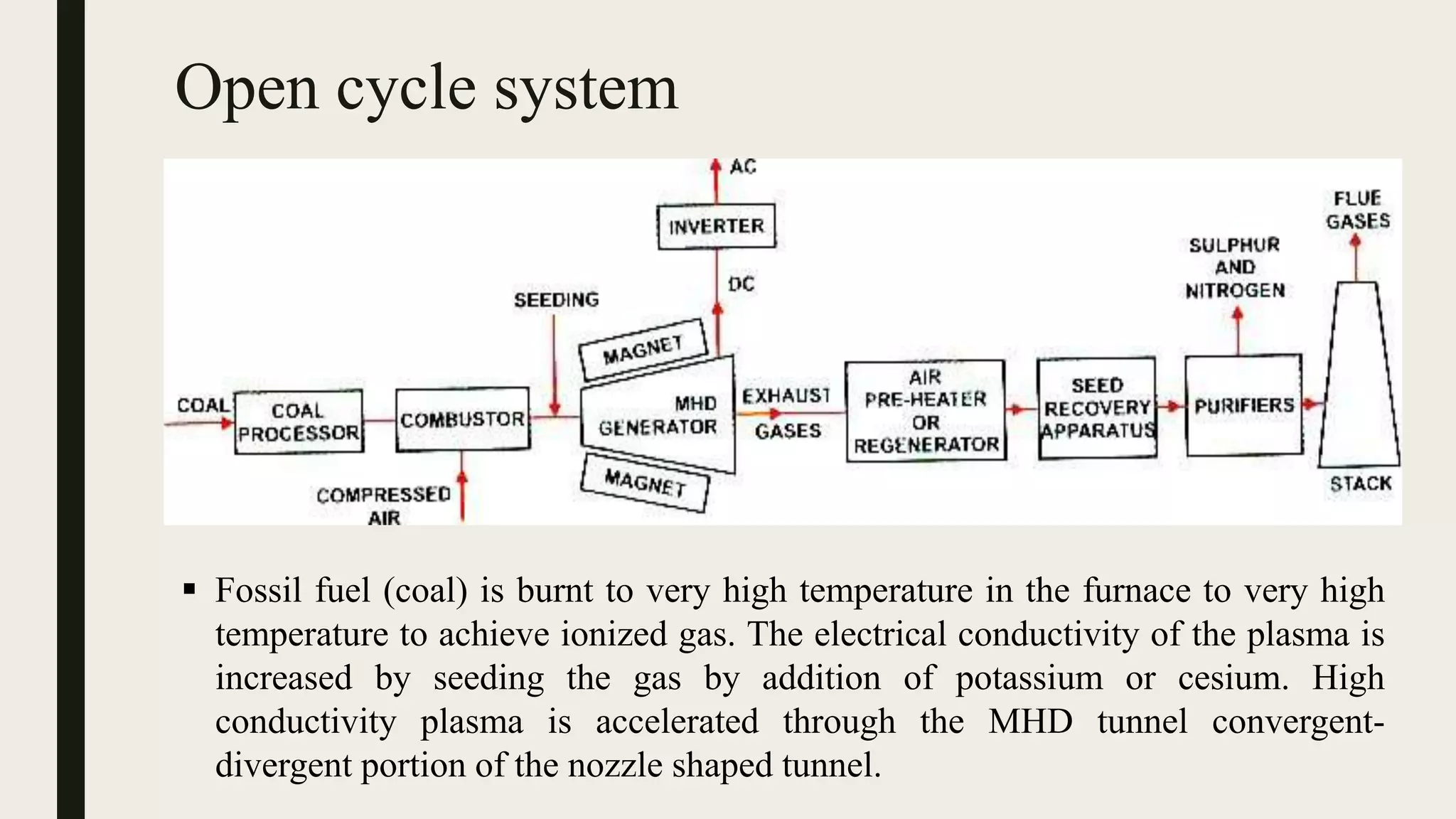

This document provides an overview of magnetohydrodynamic (MHD) power generation. MHD power generation directly converts thermal energy to electrical energy using Faraday's law of electromagnetic induction. There are two main methods - open cycle and closed cycle systems. Open cycle systems burn fossil fuels to ionize gases that are then accelerated through a magnetic field in an MHD generator. Closed cycle systems use a liquid metal and inert gas in a circulating system where the liquid metal acts as a conductor that is heated and passes through the MHD generator before being recycled. MHD power generation has advantages of high efficiency without moving parts but disadvantages of high operating temperatures that limit materials and technical challenges enhancing conductivity and magnetic fields.