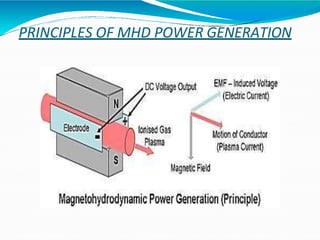

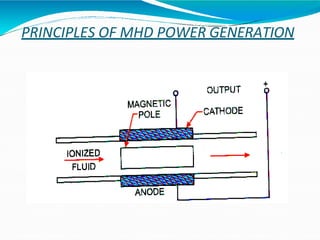

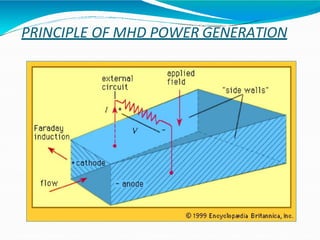

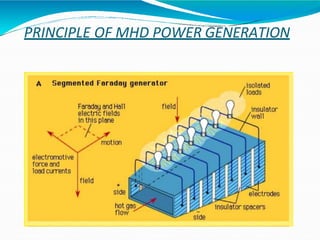

The document discusses magneto hydro dynamic (MHD) power generation. It describes MHD as using a conducting fluid like ionized gas or liquid metal that is passed through a magnetic field to generate electricity. The document outlines the principles of MHD generation and describes open and closed cycle MHD systems. The key advantages are high efficiency of around 50% and no moving parts. Limitations include the conductivity of metallic vapors and liquid incompressibility. Applications include laser power generators and space craft propulsion. Problems relate to material degradation from high temperatures and corrosion.