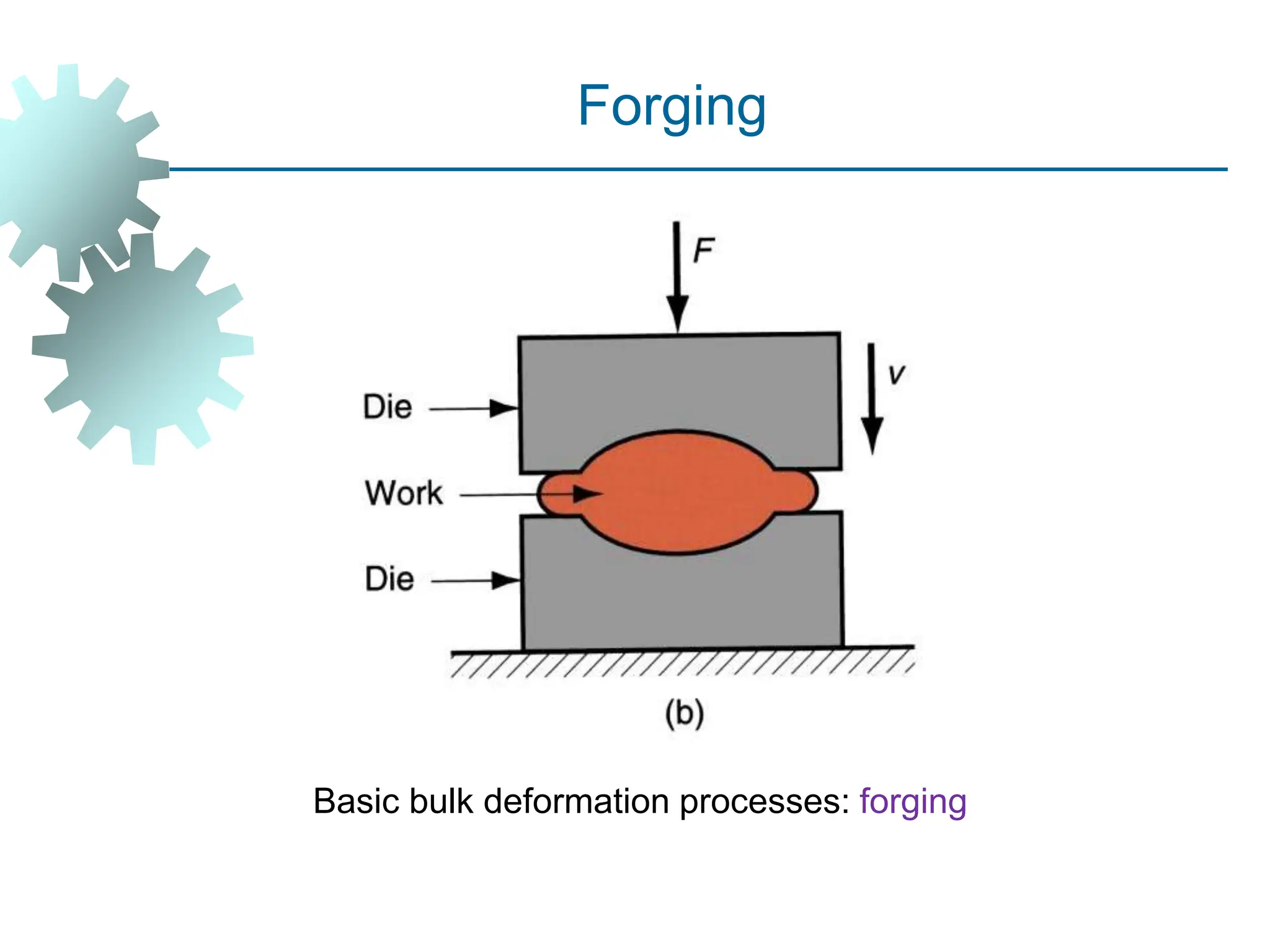

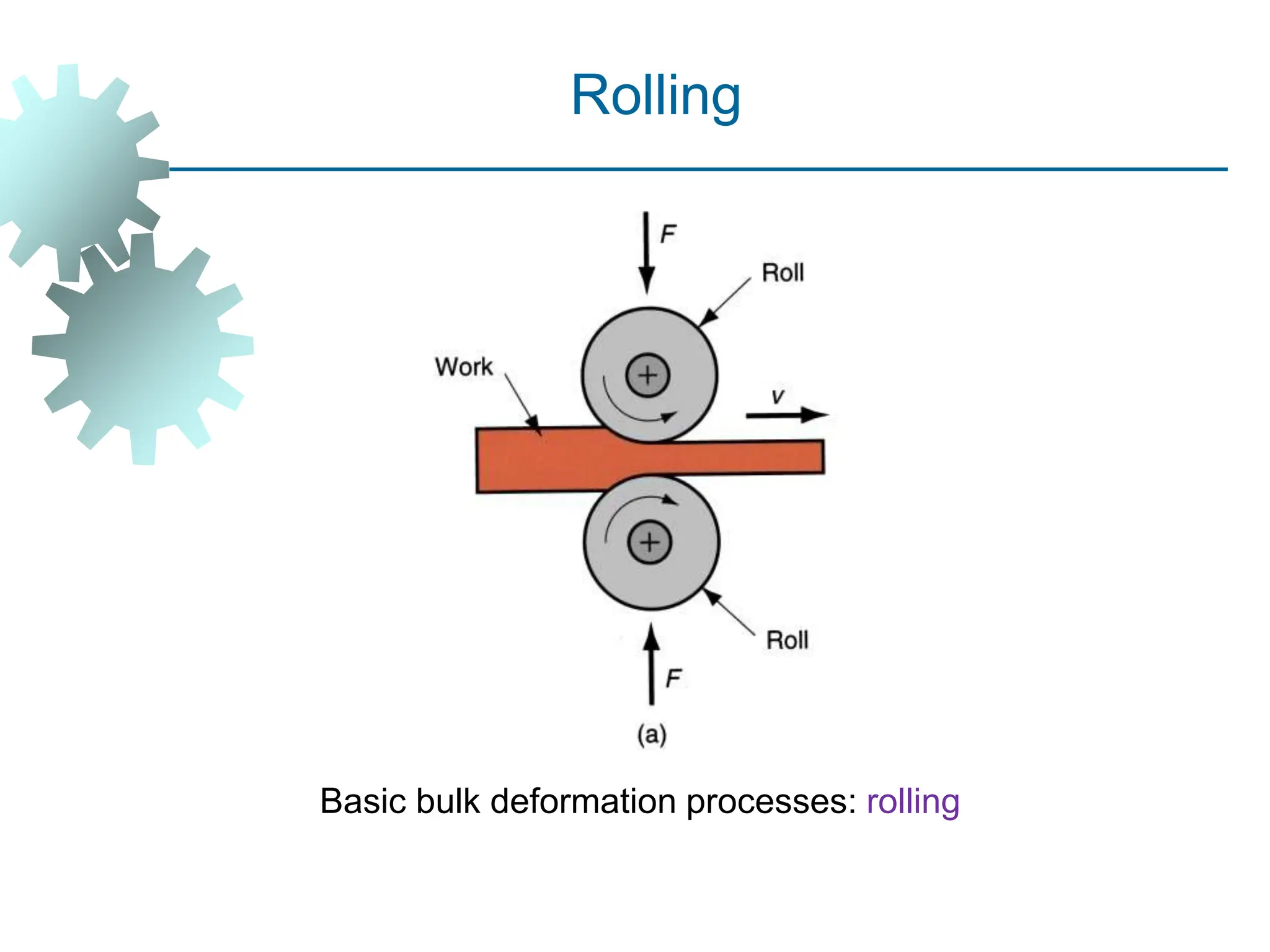

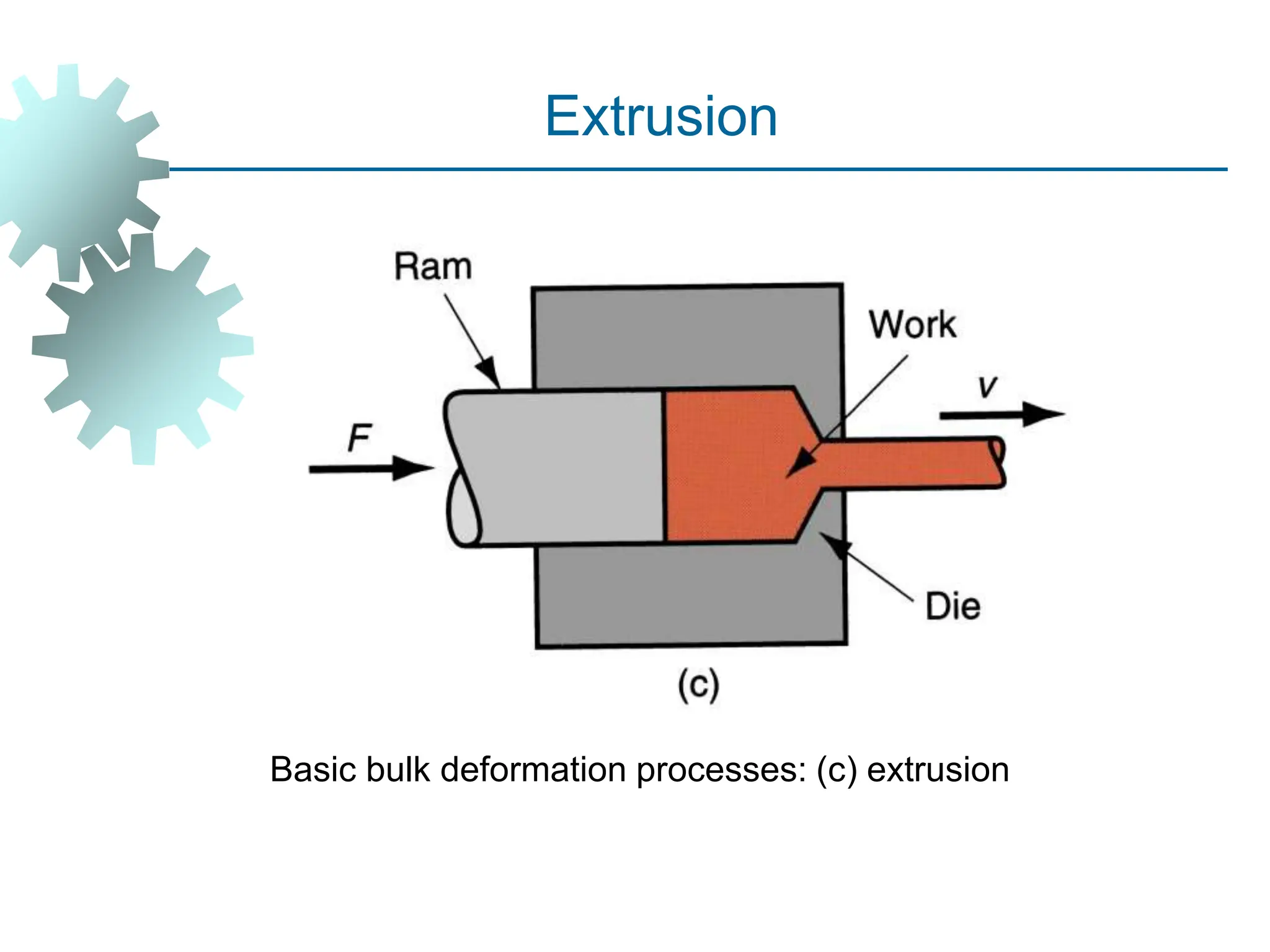

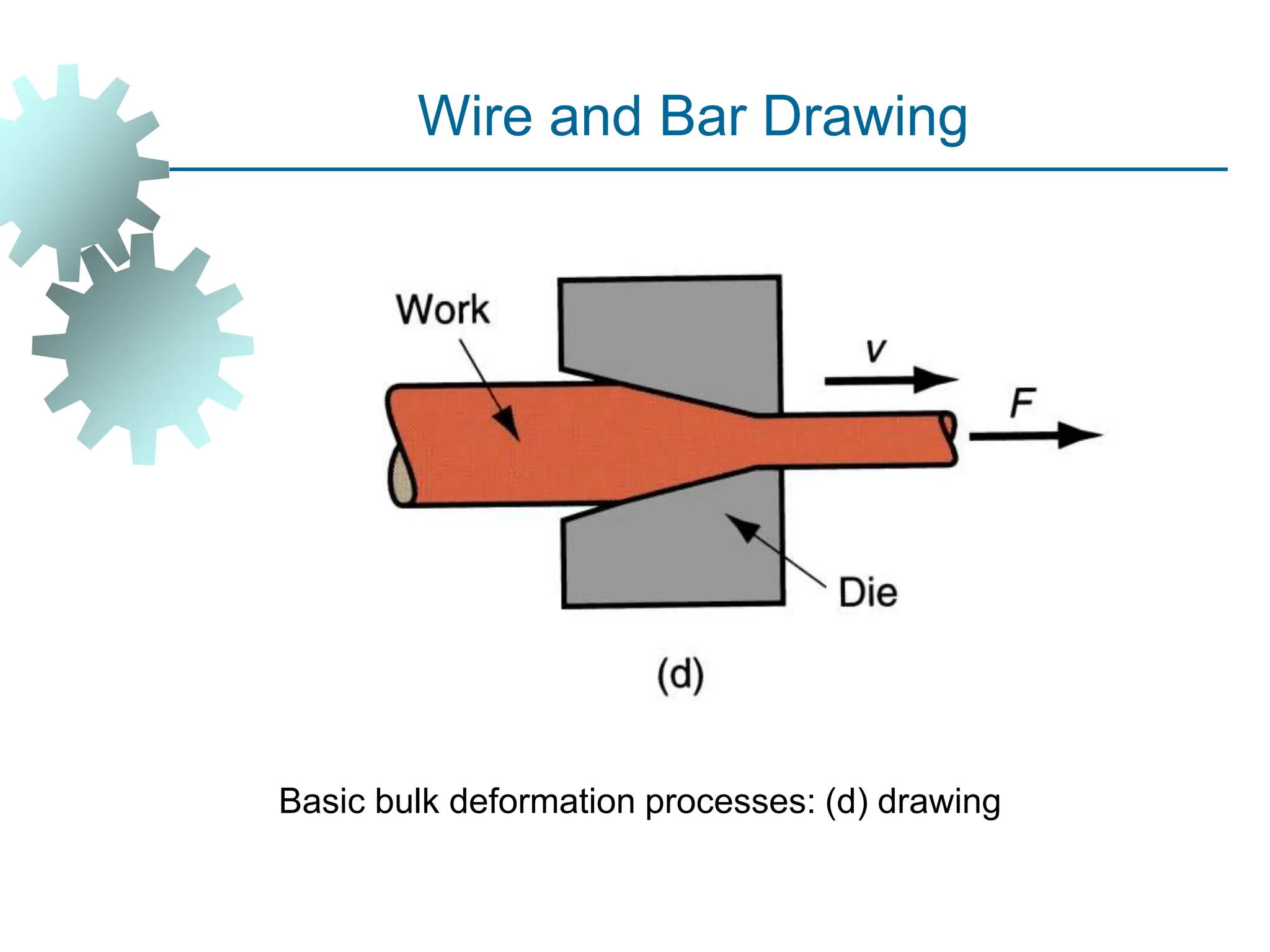

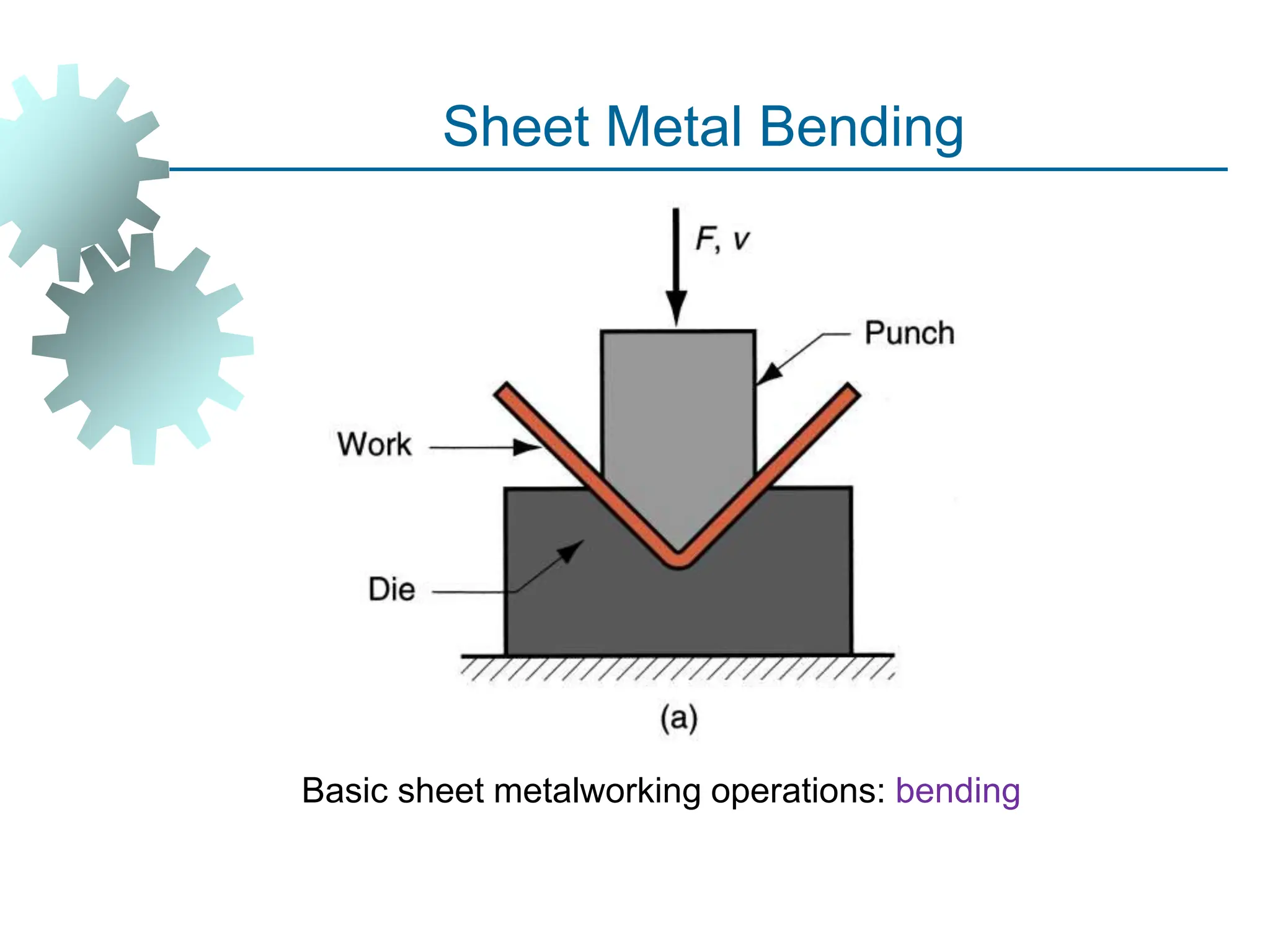

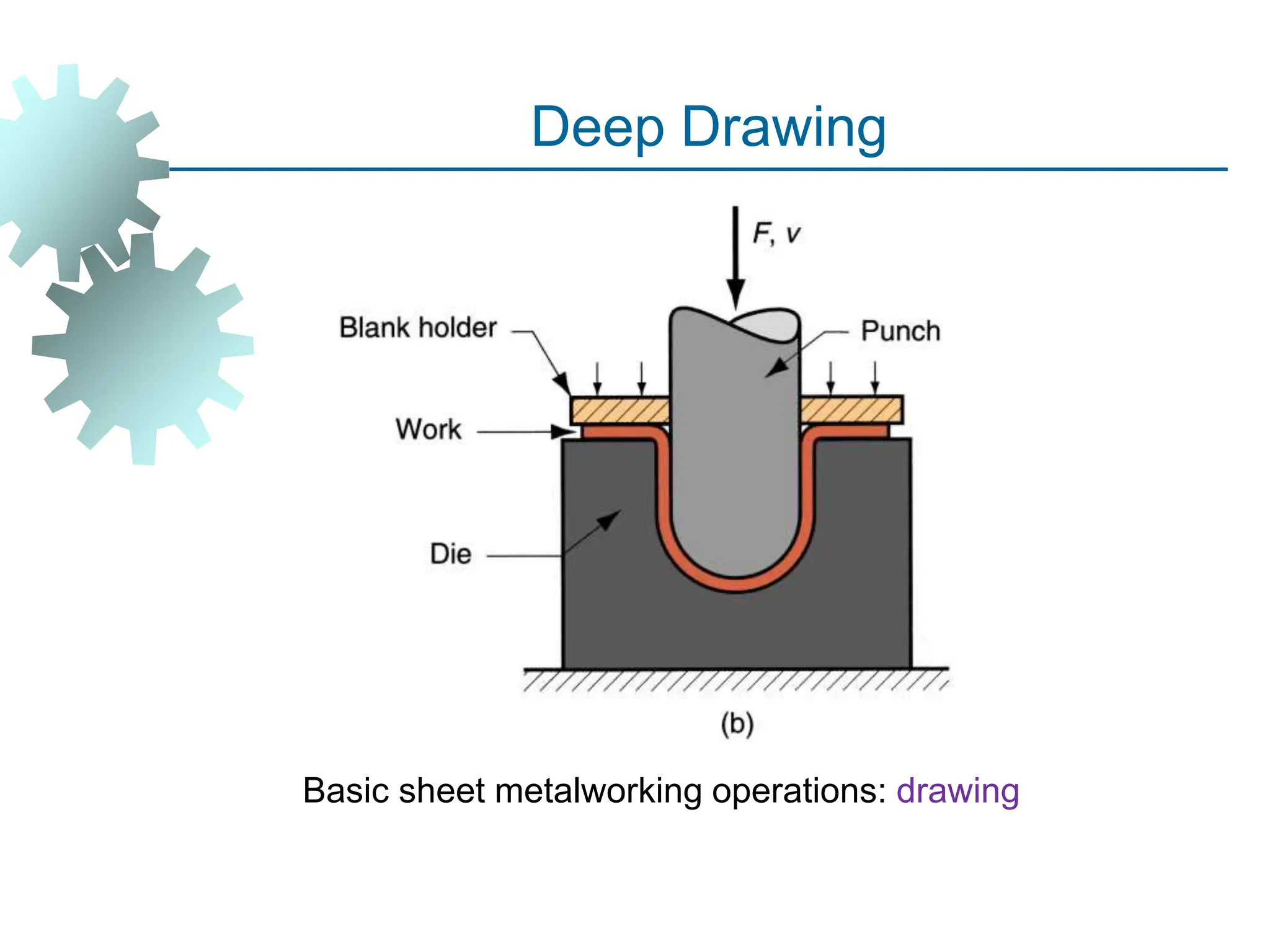

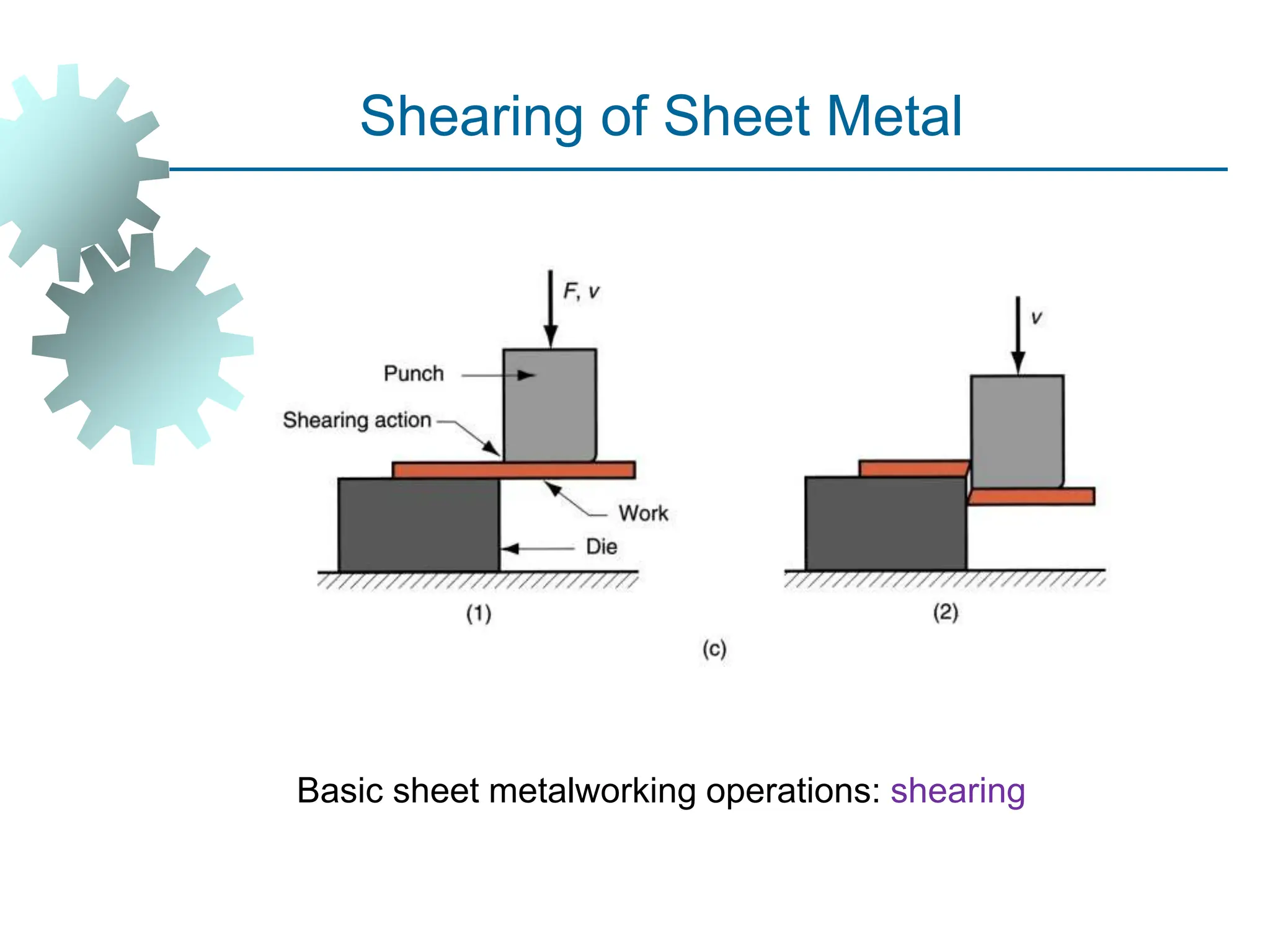

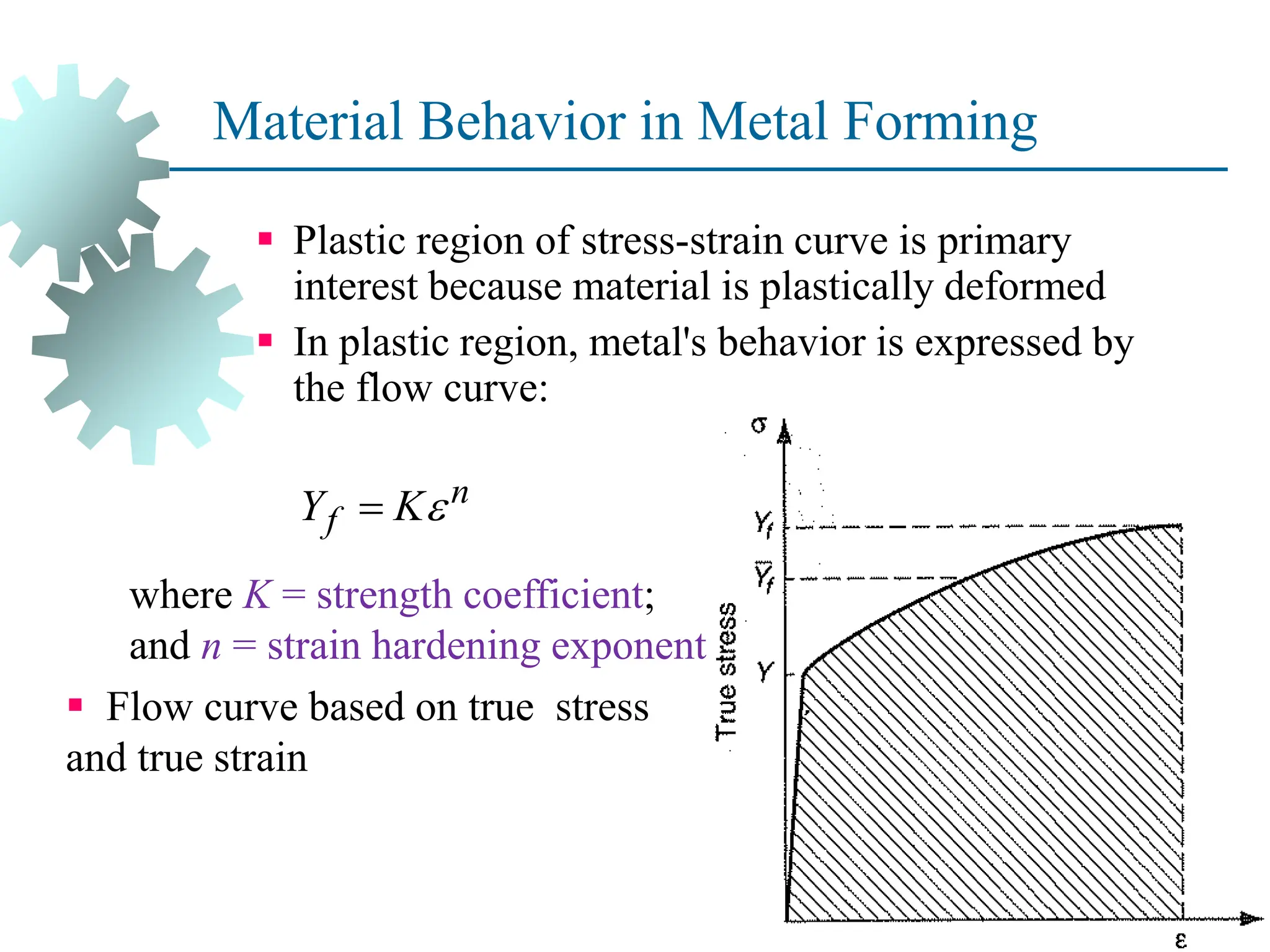

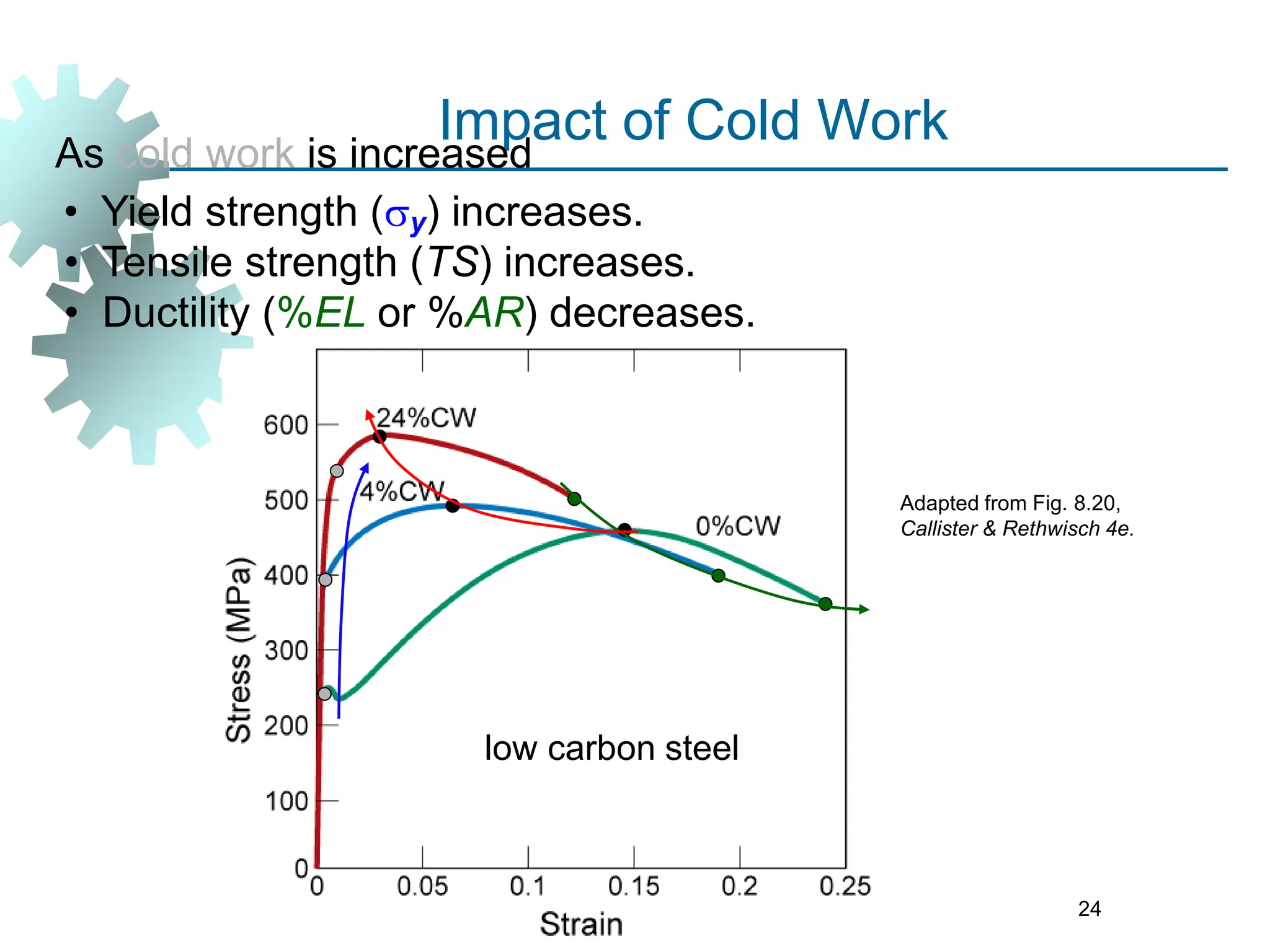

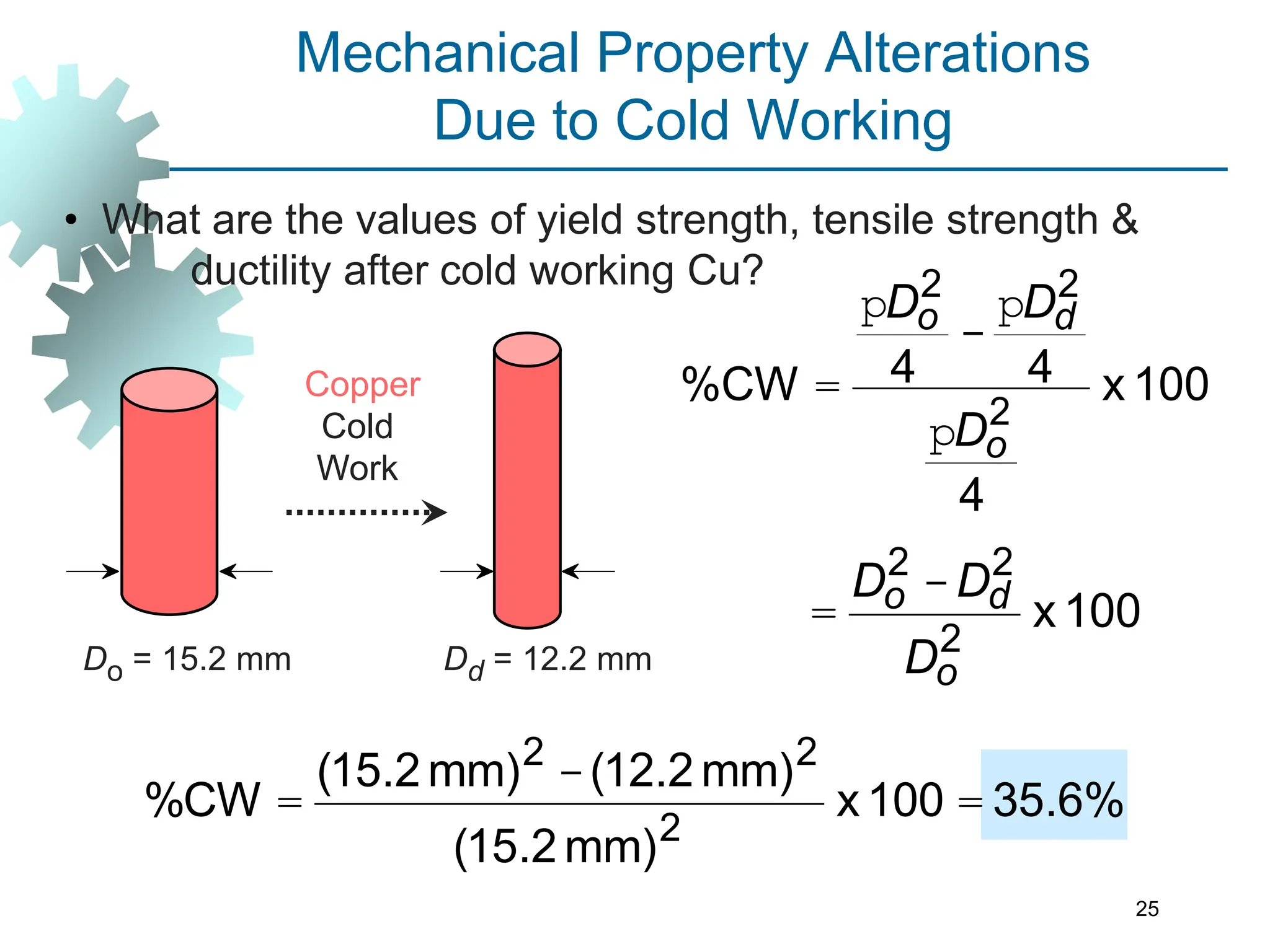

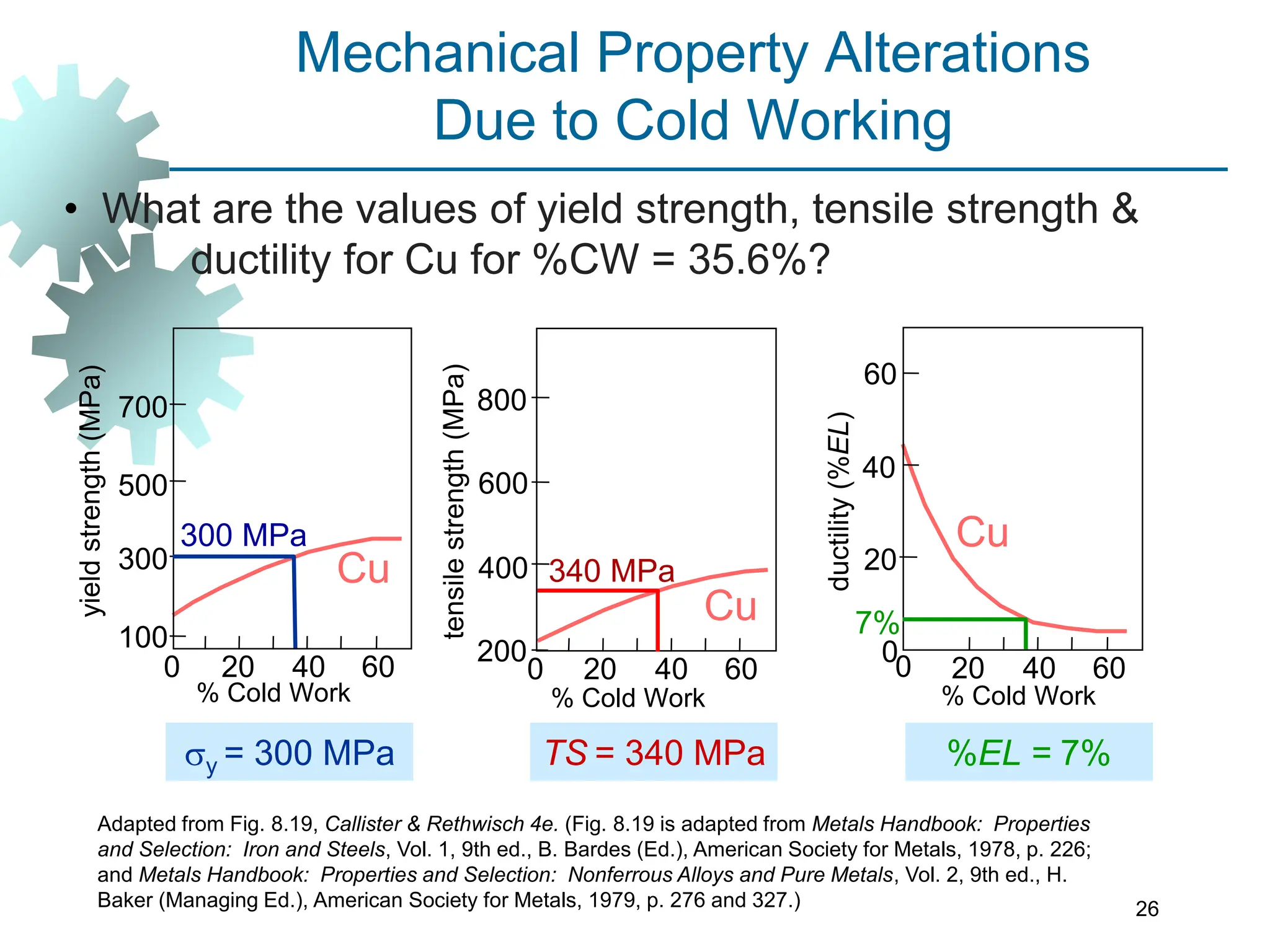

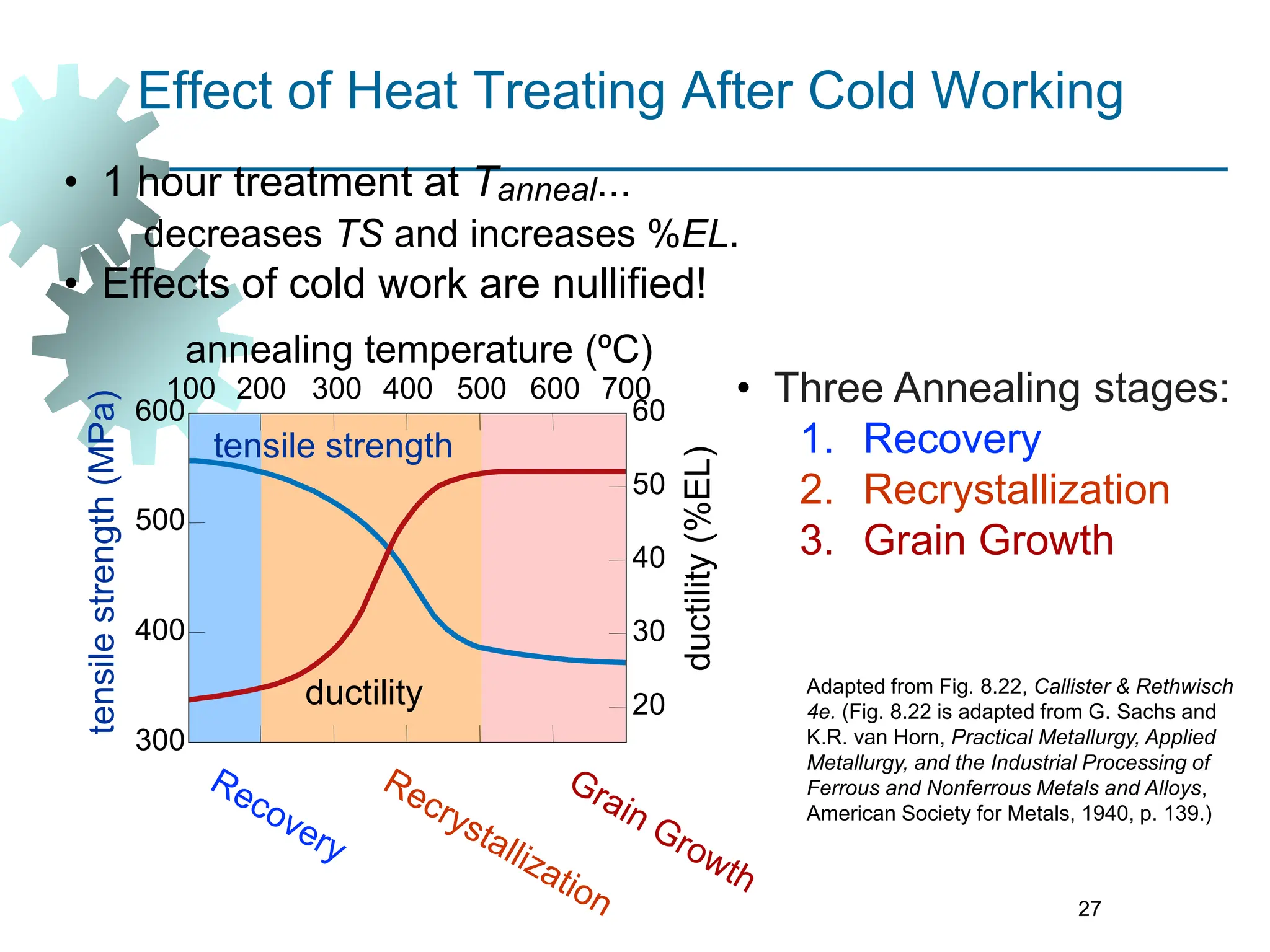

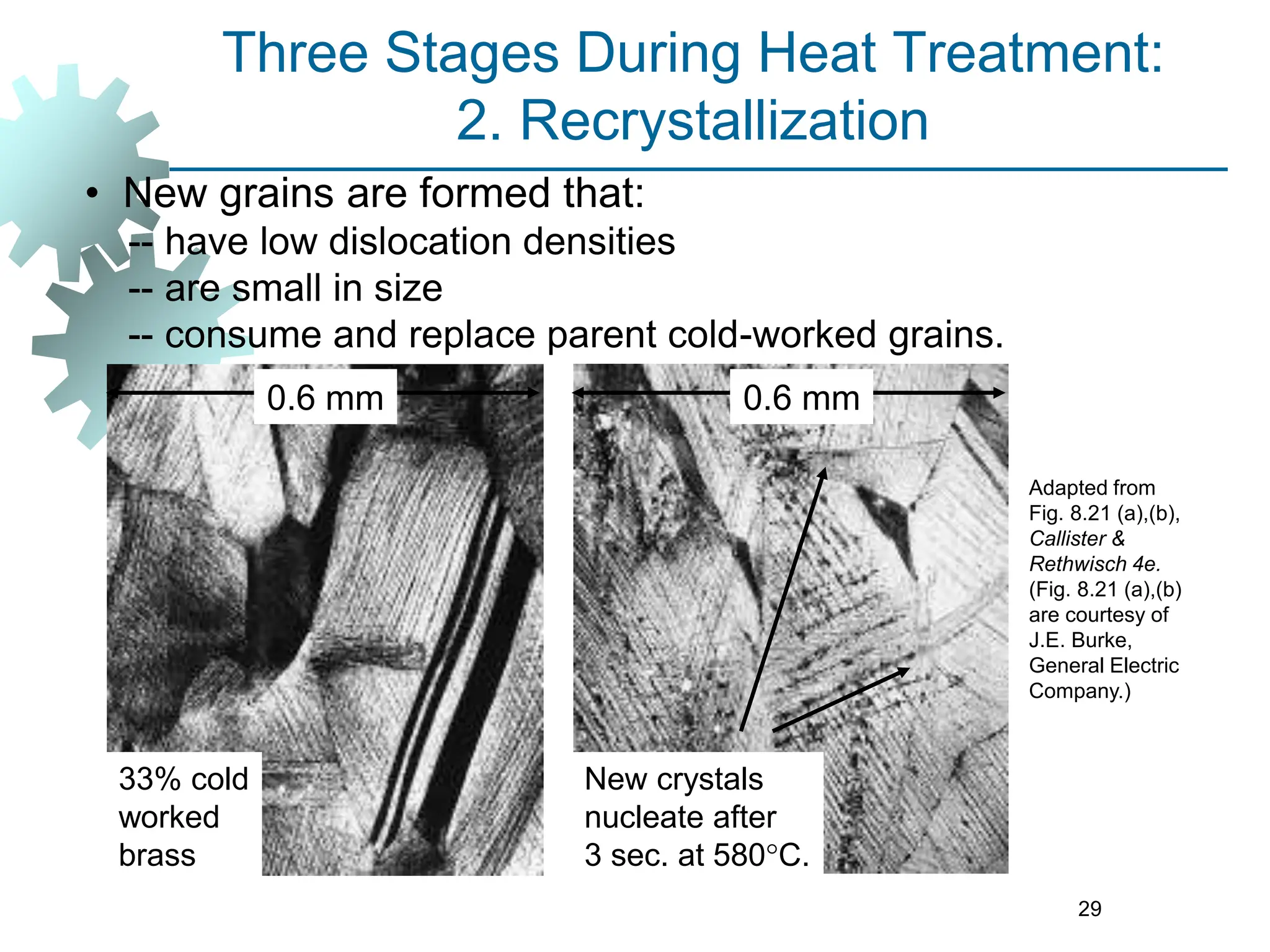

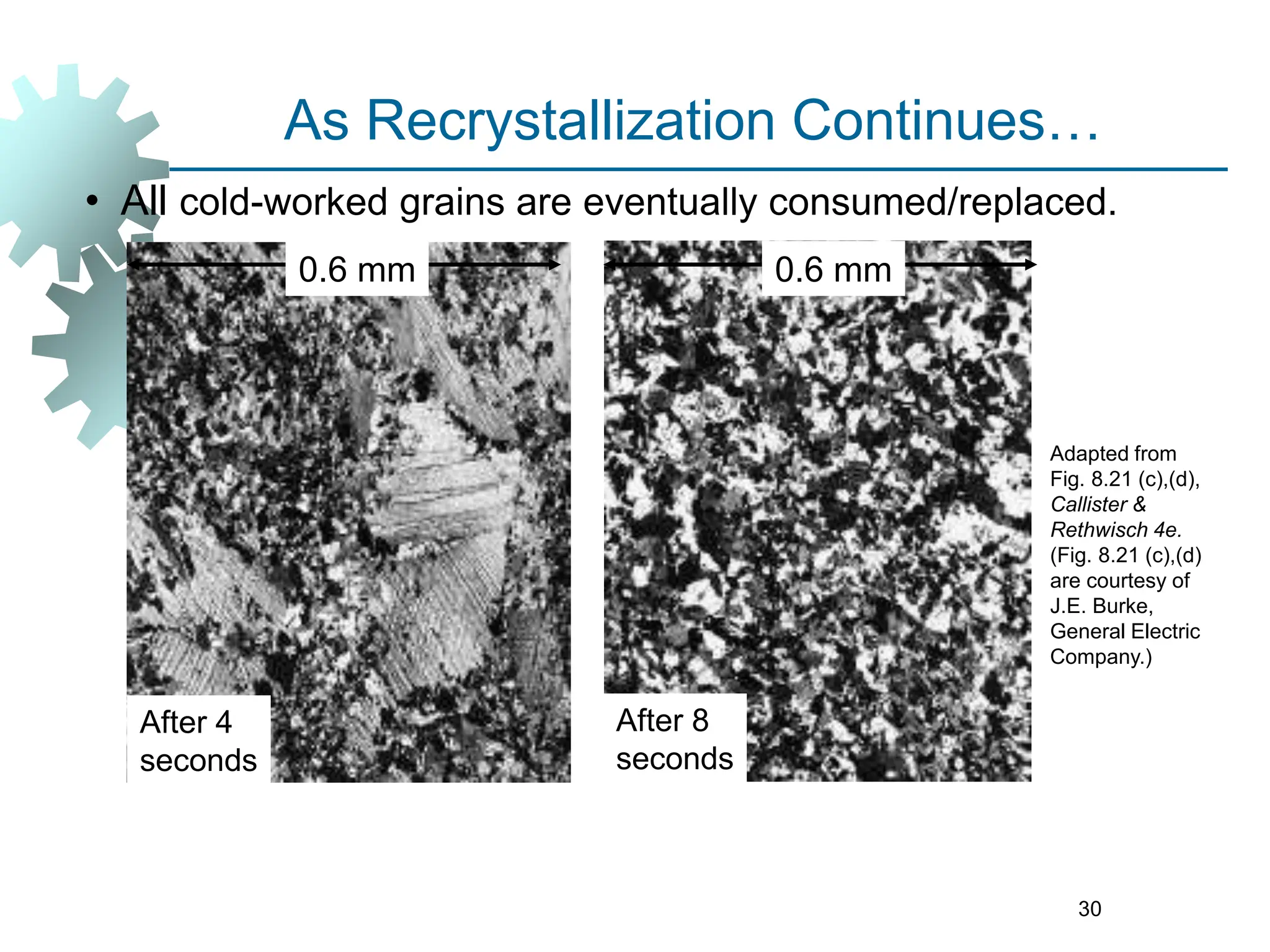

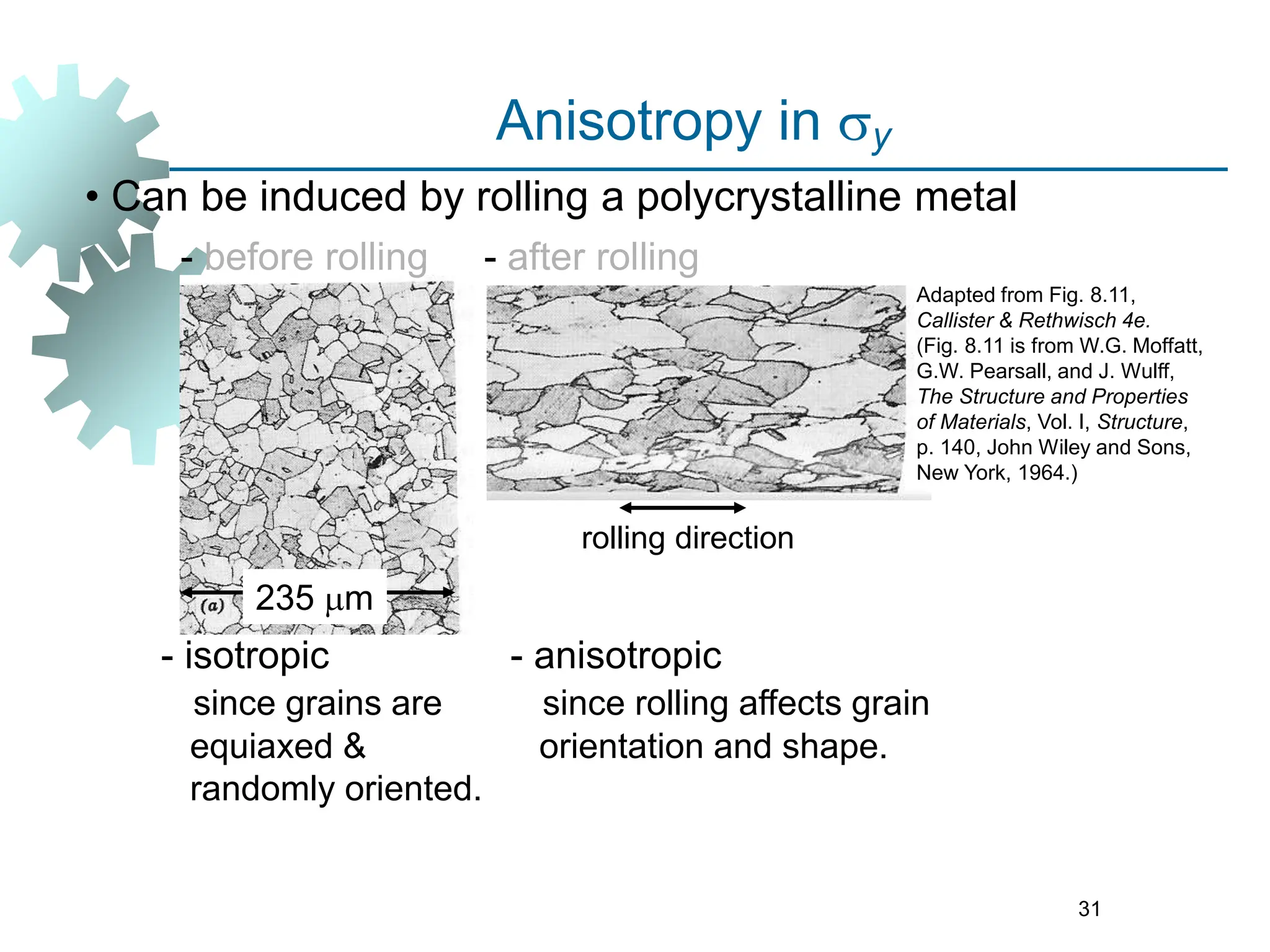

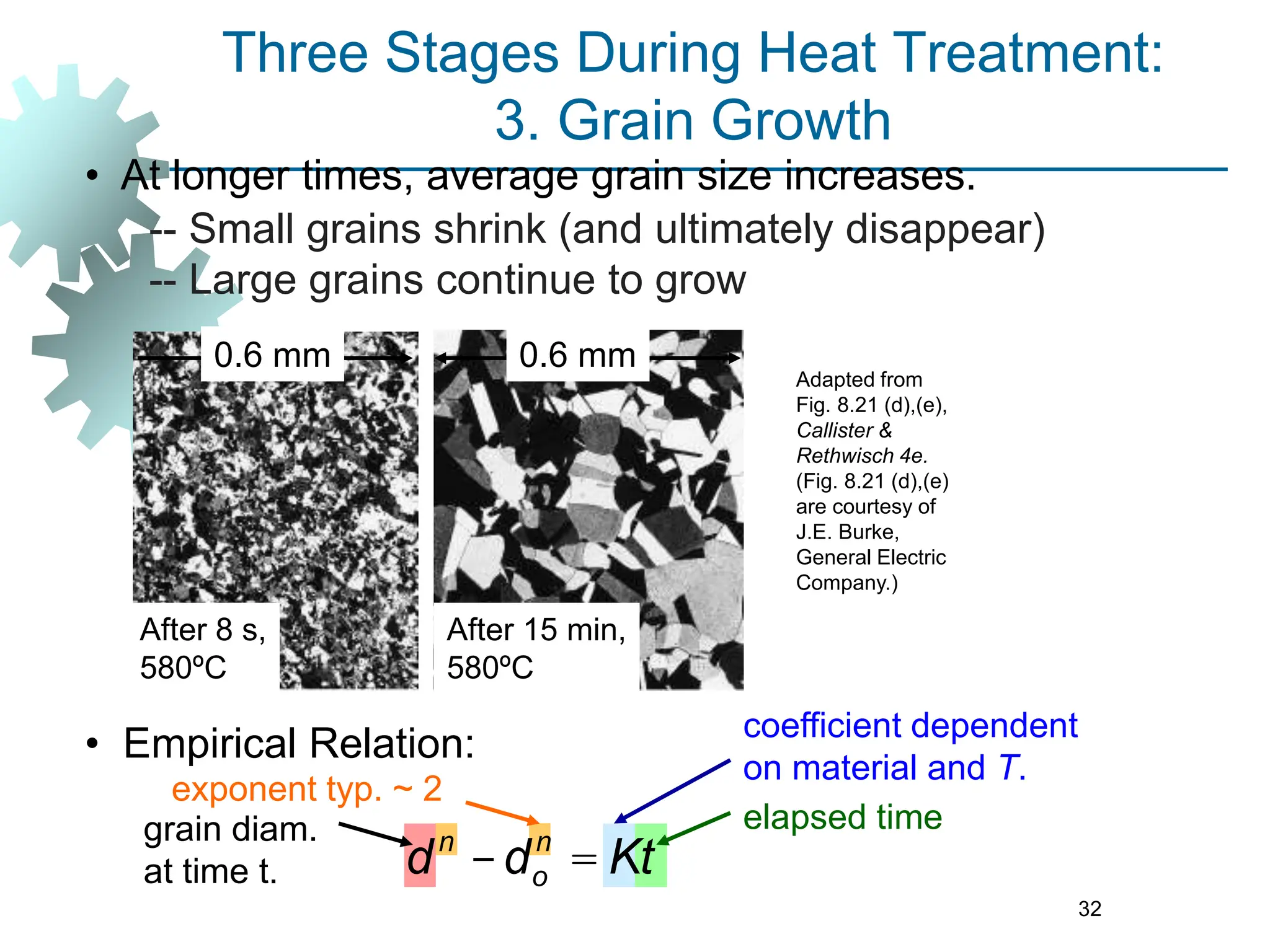

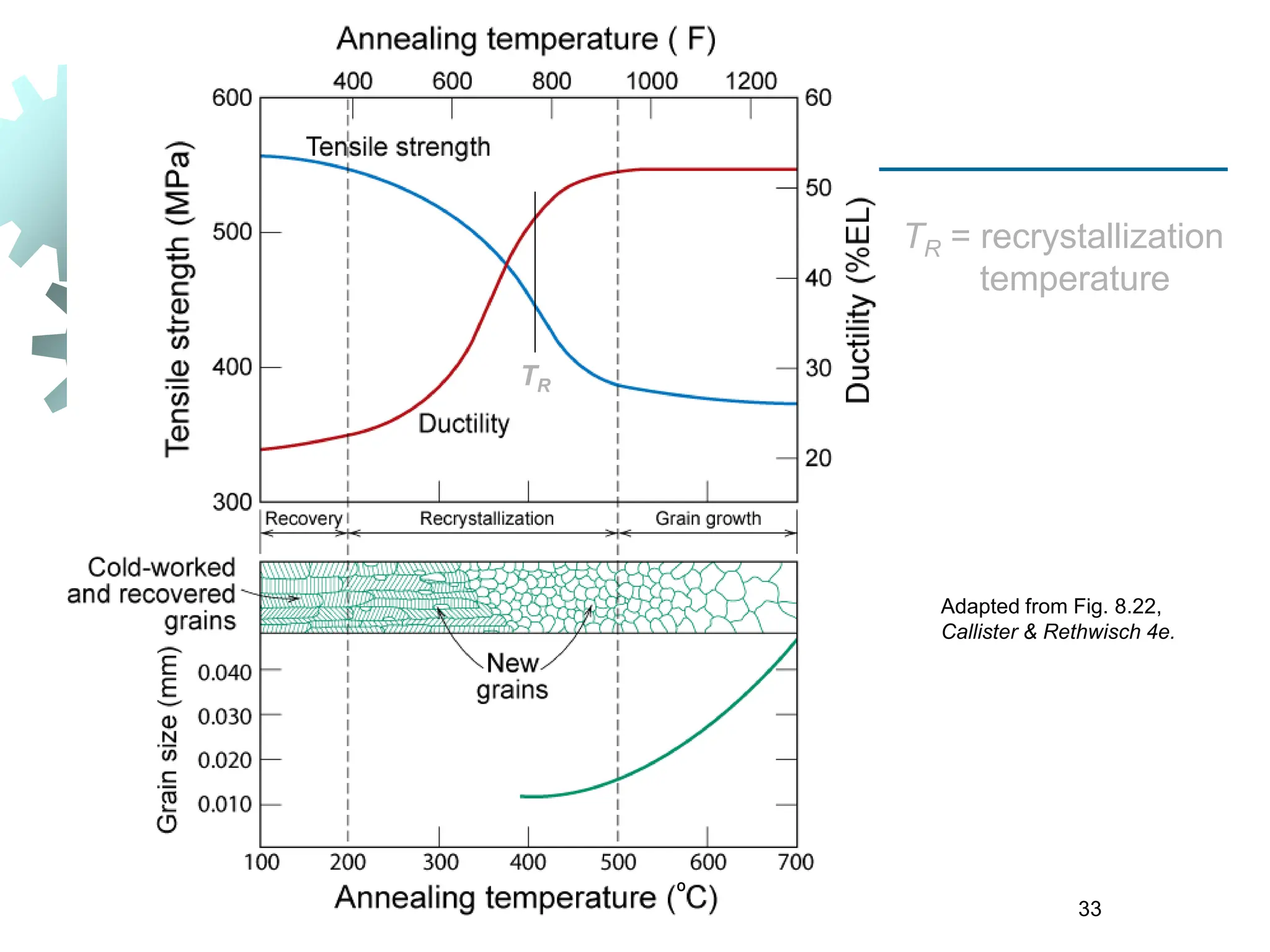

This document discusses various metal forming processes. It begins by introducing bulk deformation processes like forging, rolling, and extrusion which use compressive stresses to plastically deform metal. Sheet metalworking processes like bending and drawing are also discussed. The effects of temperature on metal formability are then covered, dividing forming into cold, warm, and hot working. Cold working gives better tolerances but requires more force. Heat treating processes like annealing, recrystallization, and grain growth are also summarized.