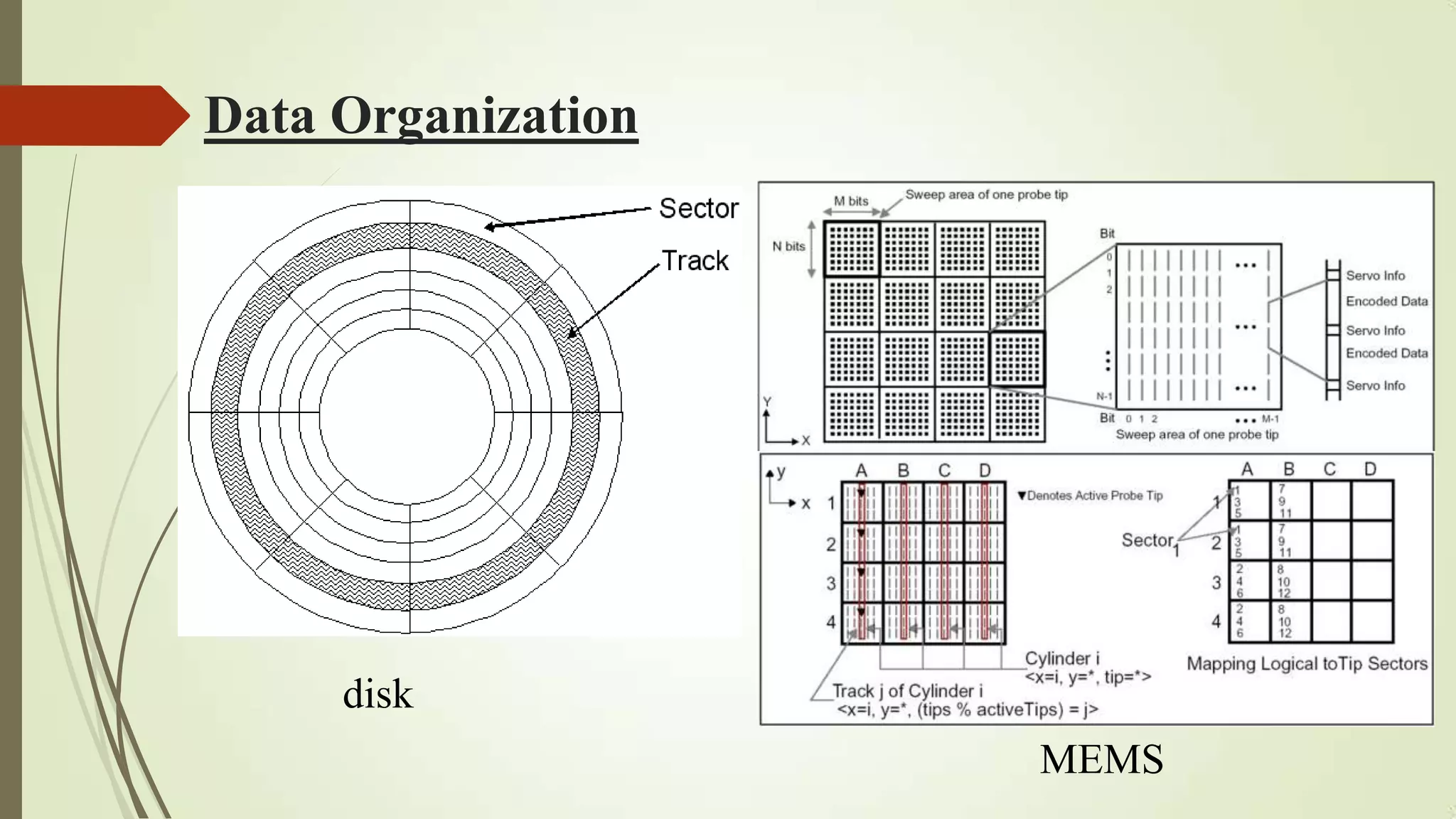

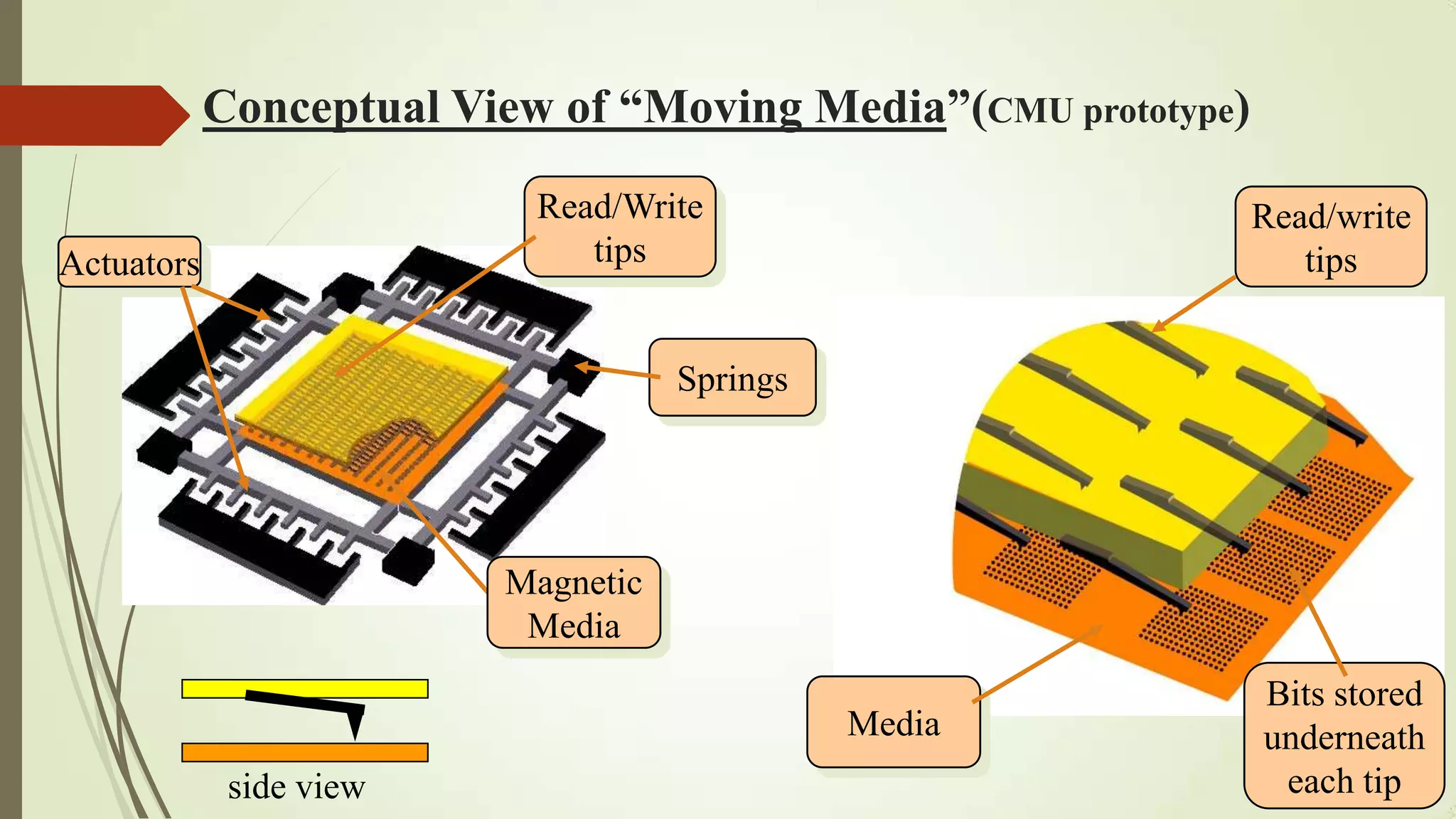

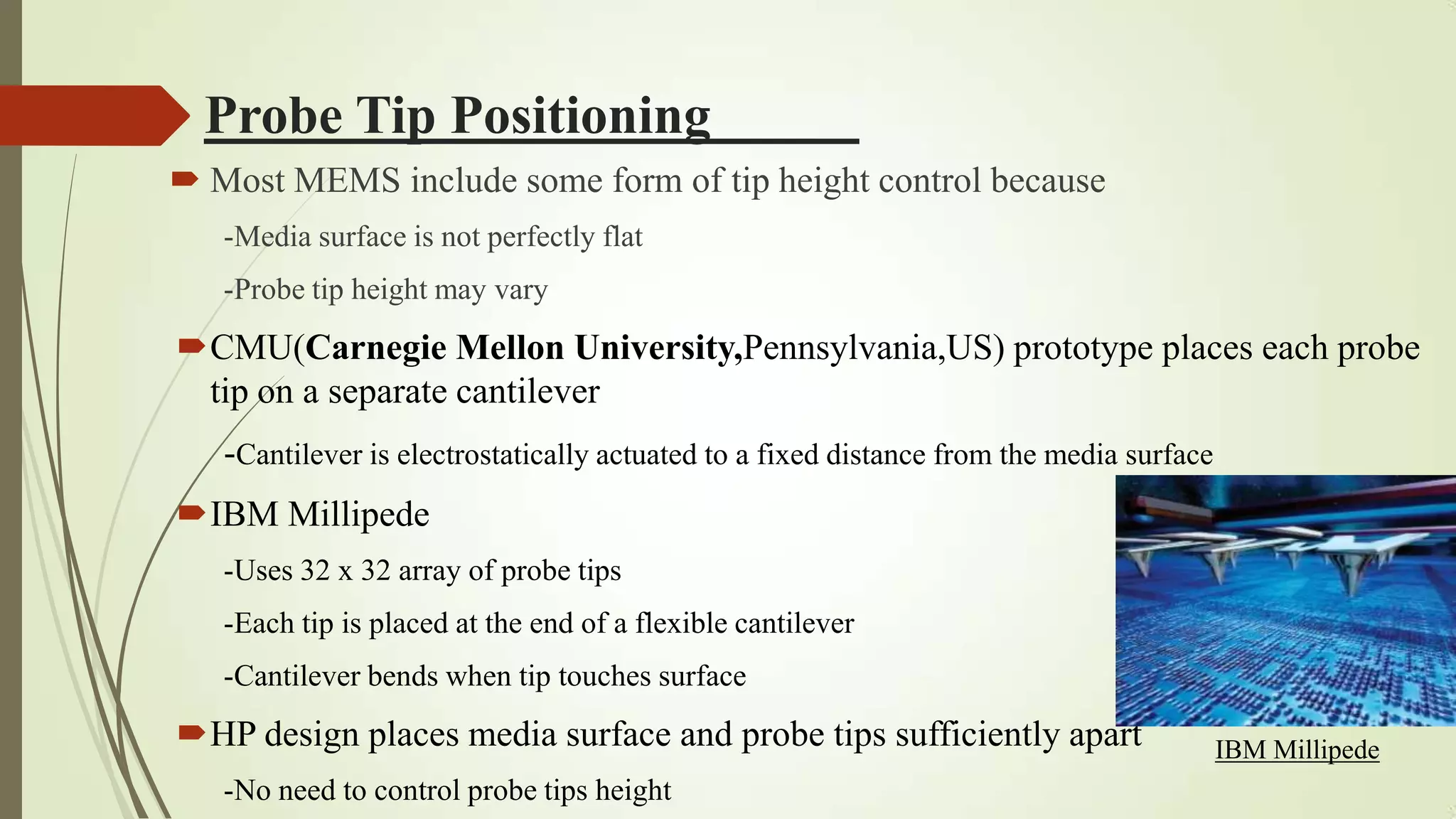

(1) MEMS-based mass storage devices could revolutionize computer architecture by providing faster access times, lower costs, and smaller sizes than traditional hard disk drives. (2) Proposed MEMS devices would use microscopic probe tips on a movable sled to read and write data on a magnetic storage surface, allowing for faster access and higher densities than rotating disks. (3) Major challenges include fabricating the probe tips to be compatible with CMOS circuits and managing failures, but potential applications include use in devices like laptops, cameras, and systems-on-a-chip due to advantages in speed, size, cost and robustness over disk drives.