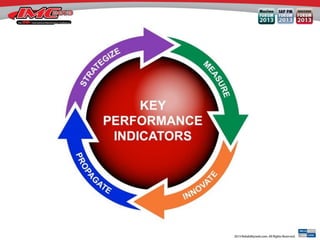

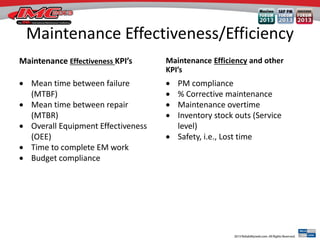

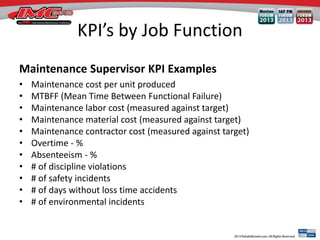

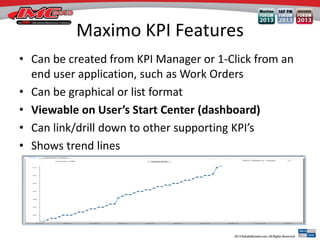

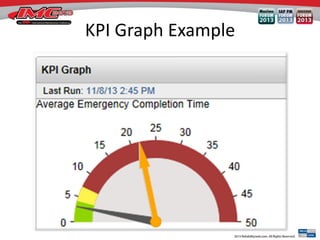

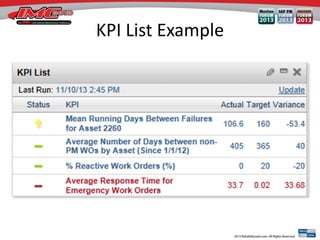

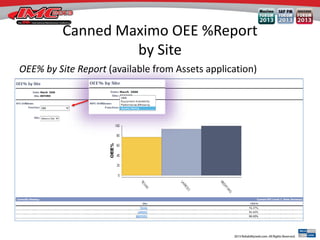

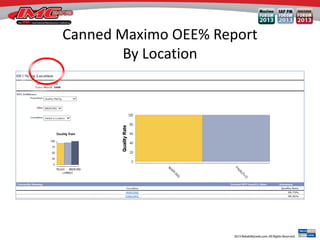

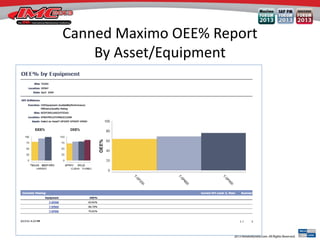

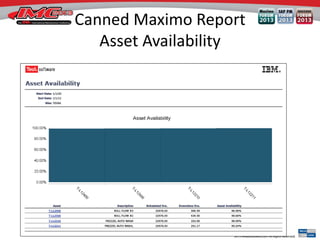

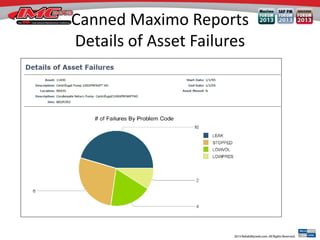

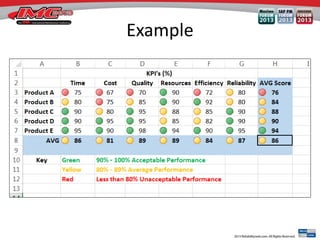

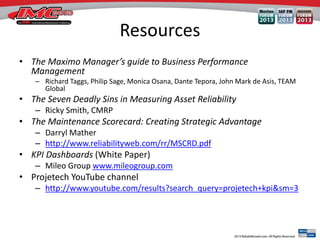

The document discusses the importance of key performance indicators (KPIs) in supporting reliability strategies within organizations, highlighting their role in measuring program effectiveness and aligning with corporate objectives. It emphasizes the need for relevant data and priority setting in maintenance activities to achieve better outcomes. Additionally, it provides insights on the use of IBM Maximo for KPI management and reporting, offering examples and best practices for effective implementation.