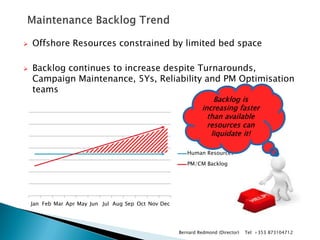

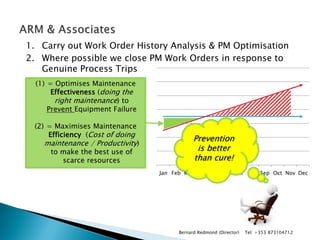

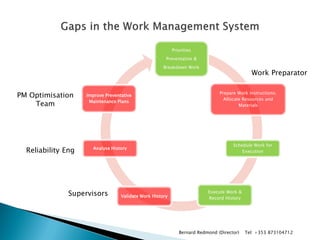

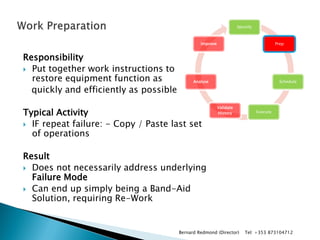

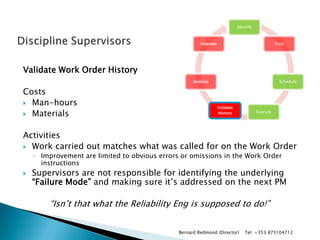

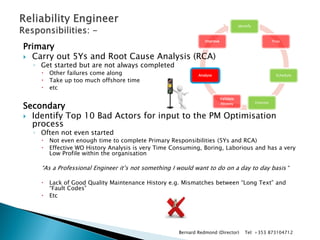

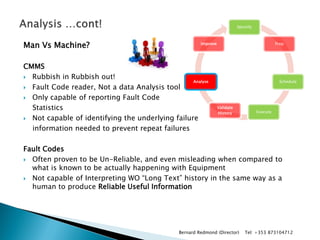

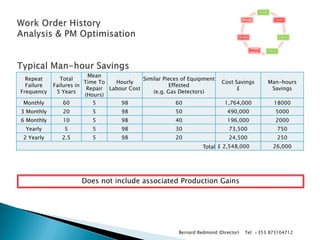

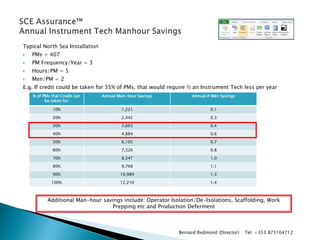

This document outlines issues facing an oil and gas facility such as declining output, aging assets, skills shortages, and increasing maintenance backlogs. It proposes that the company hire ARM & Associates to implement a risk-free program focused on preventative maintenance optimization and reliability engineering. This program would analyze work order history to identify failure modes, improve maintenance plans and schedules, and validate work. It claims this approach could significantly reduce costs and man-hours compared to the status quo.