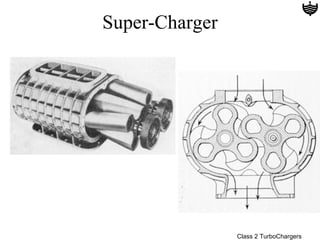

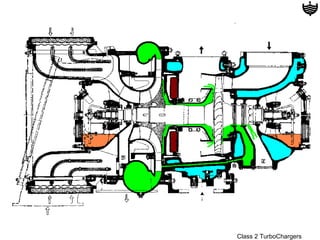

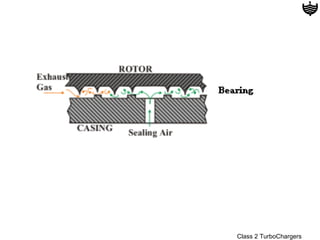

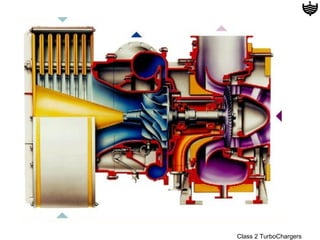

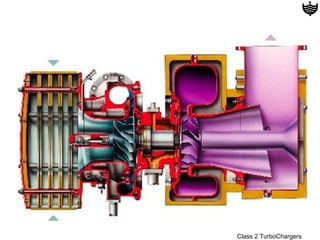

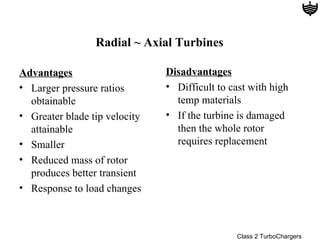

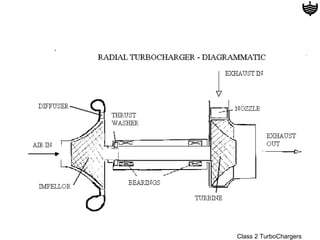

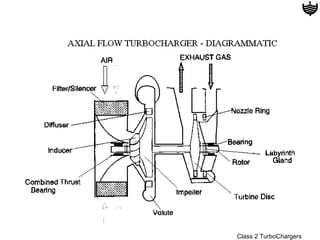

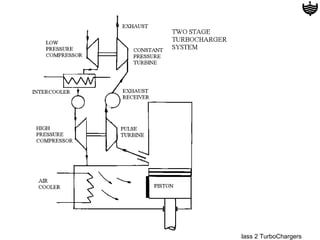

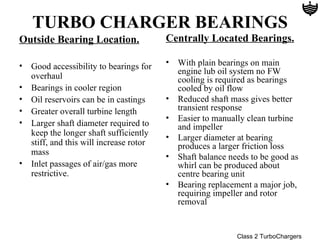

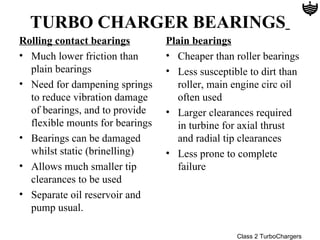

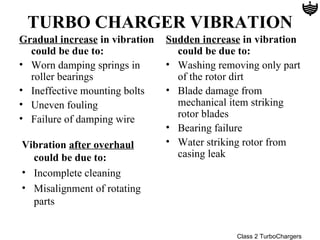

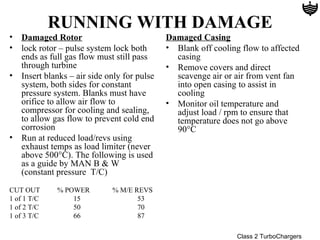

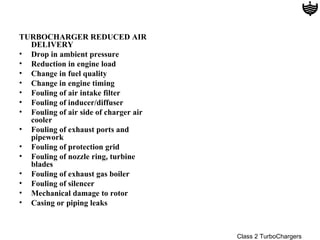

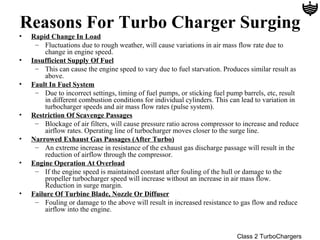

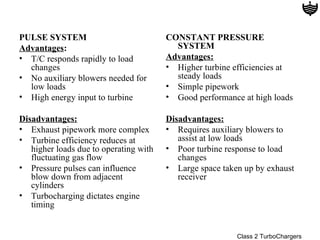

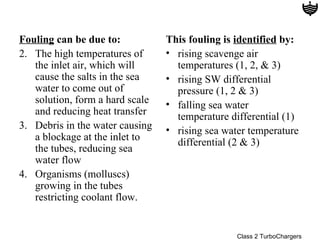

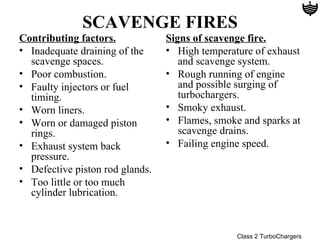

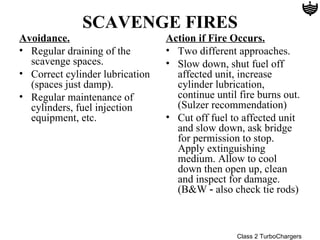

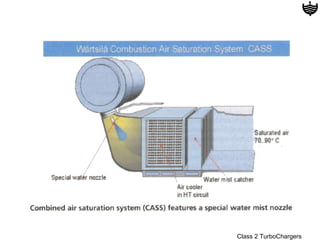

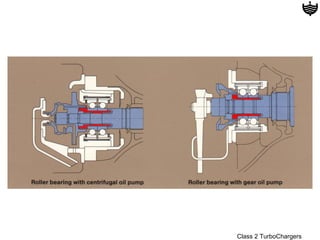

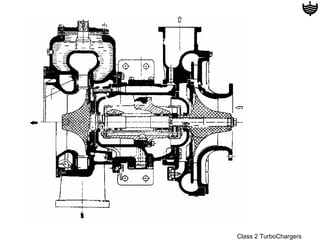

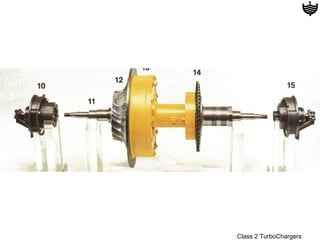

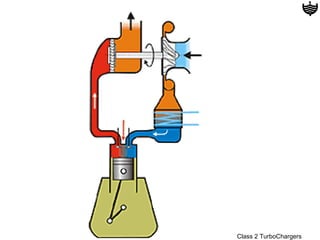

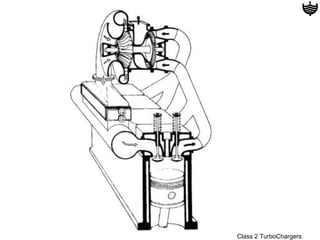

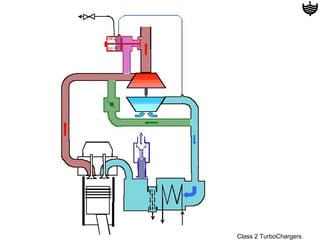

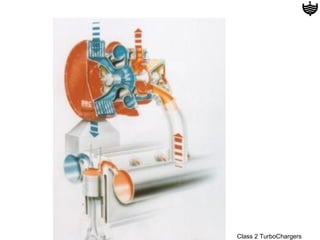

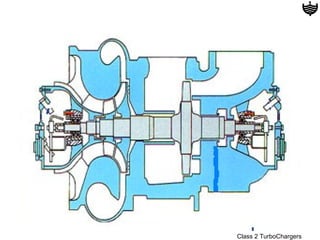

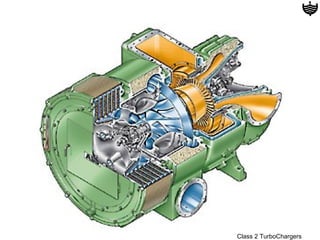

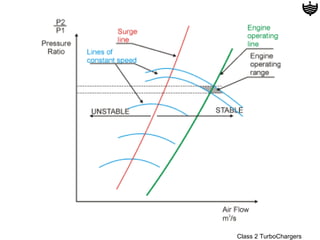

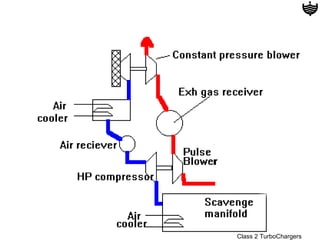

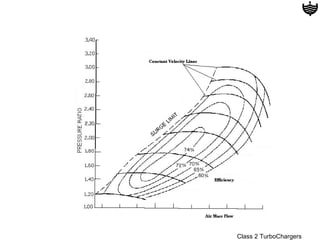

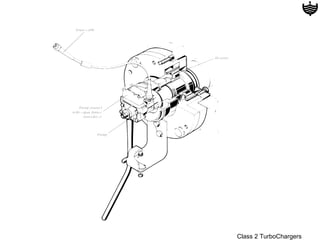

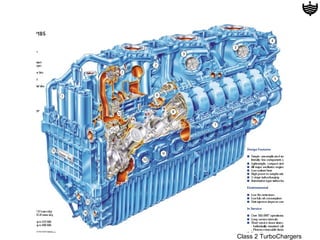

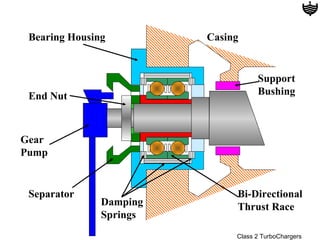

The document discusses turbochargers, including their advantages over other charging methods like superchargers. It describes how turbochargers can increase engine power and efficiency while reducing engine size. It also covers various turbocharger components like turbines, bearings and vibration, as well as operating issues like fouling, surging and fires in the scavenge system.