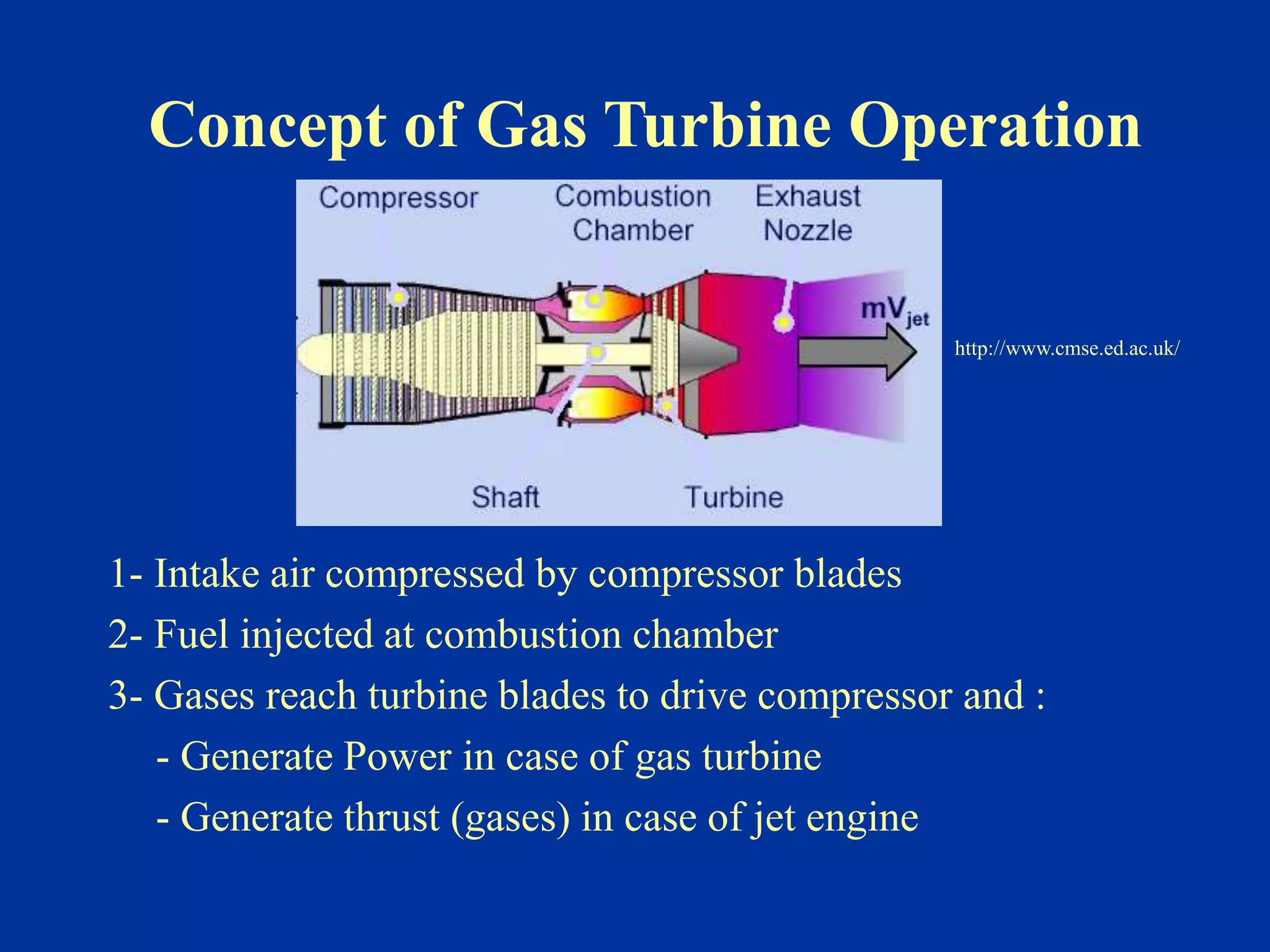

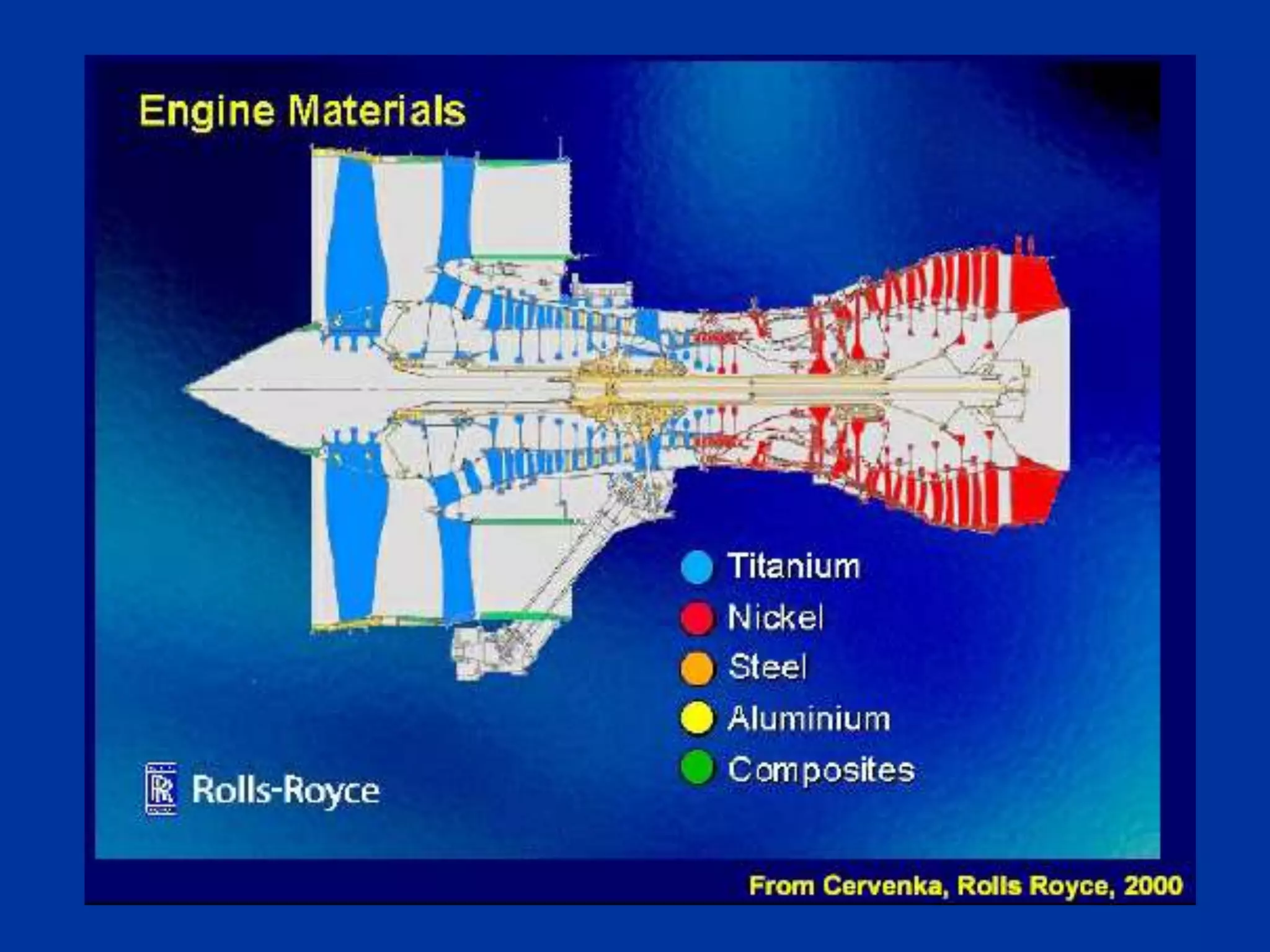

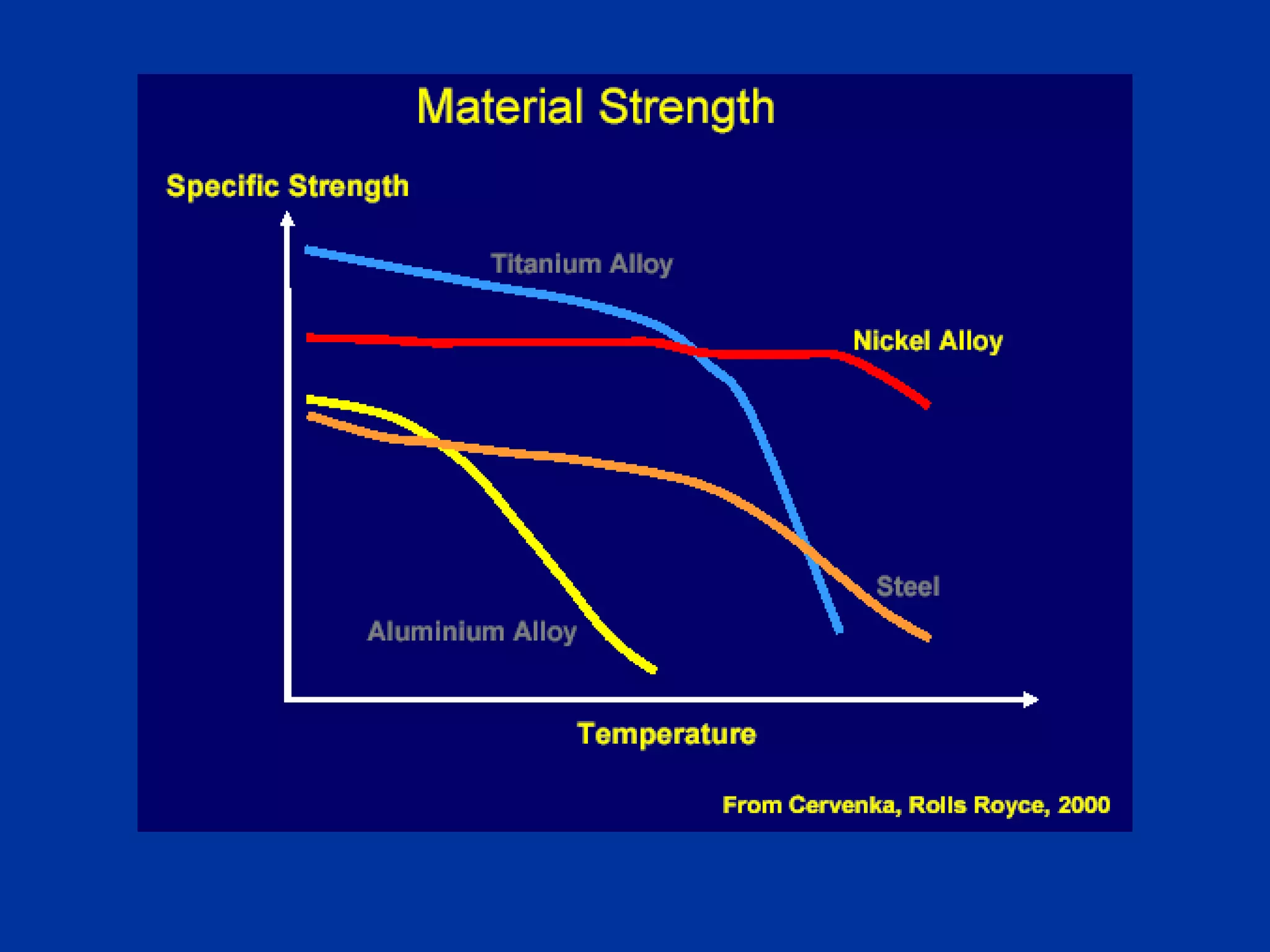

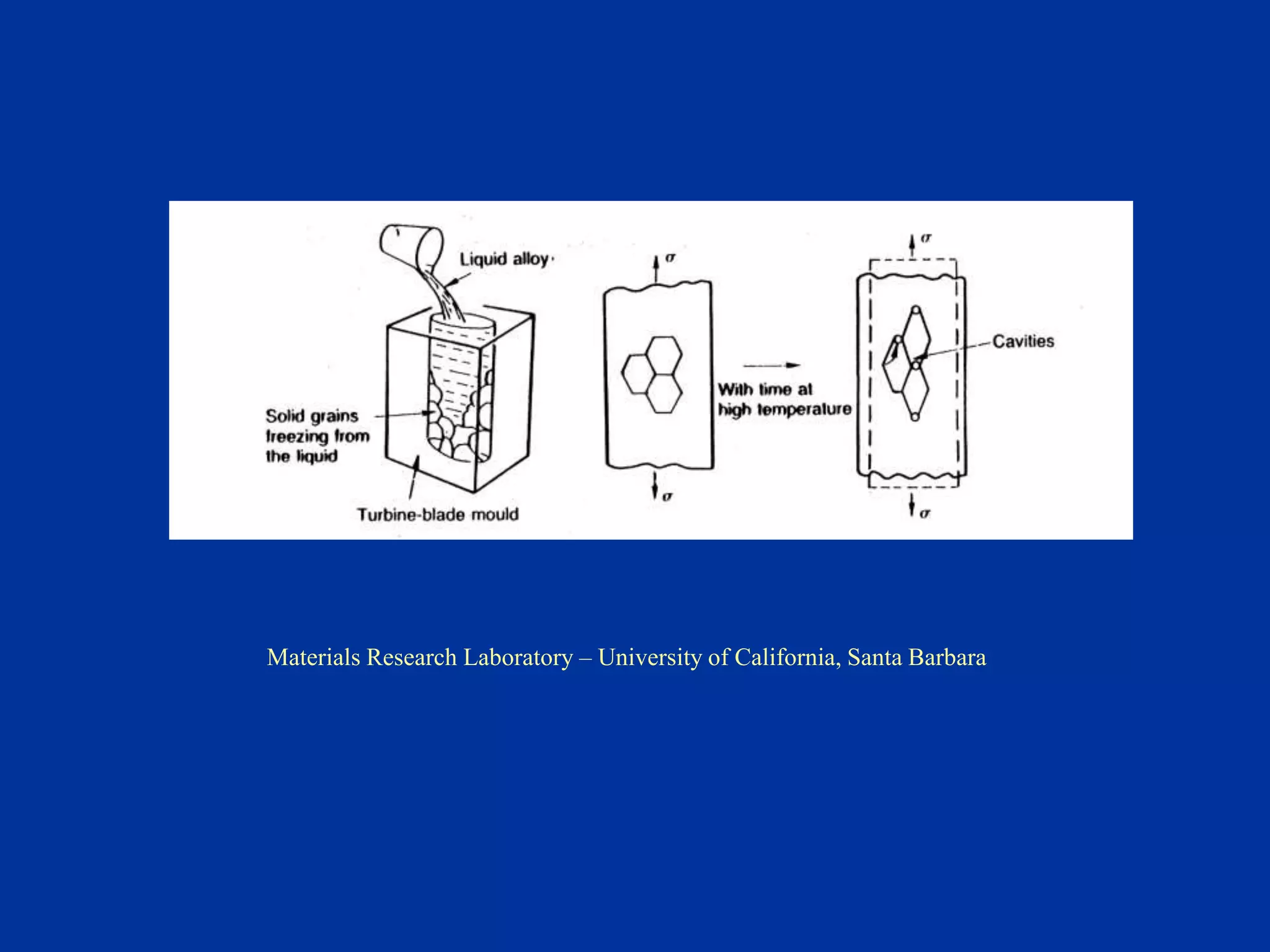

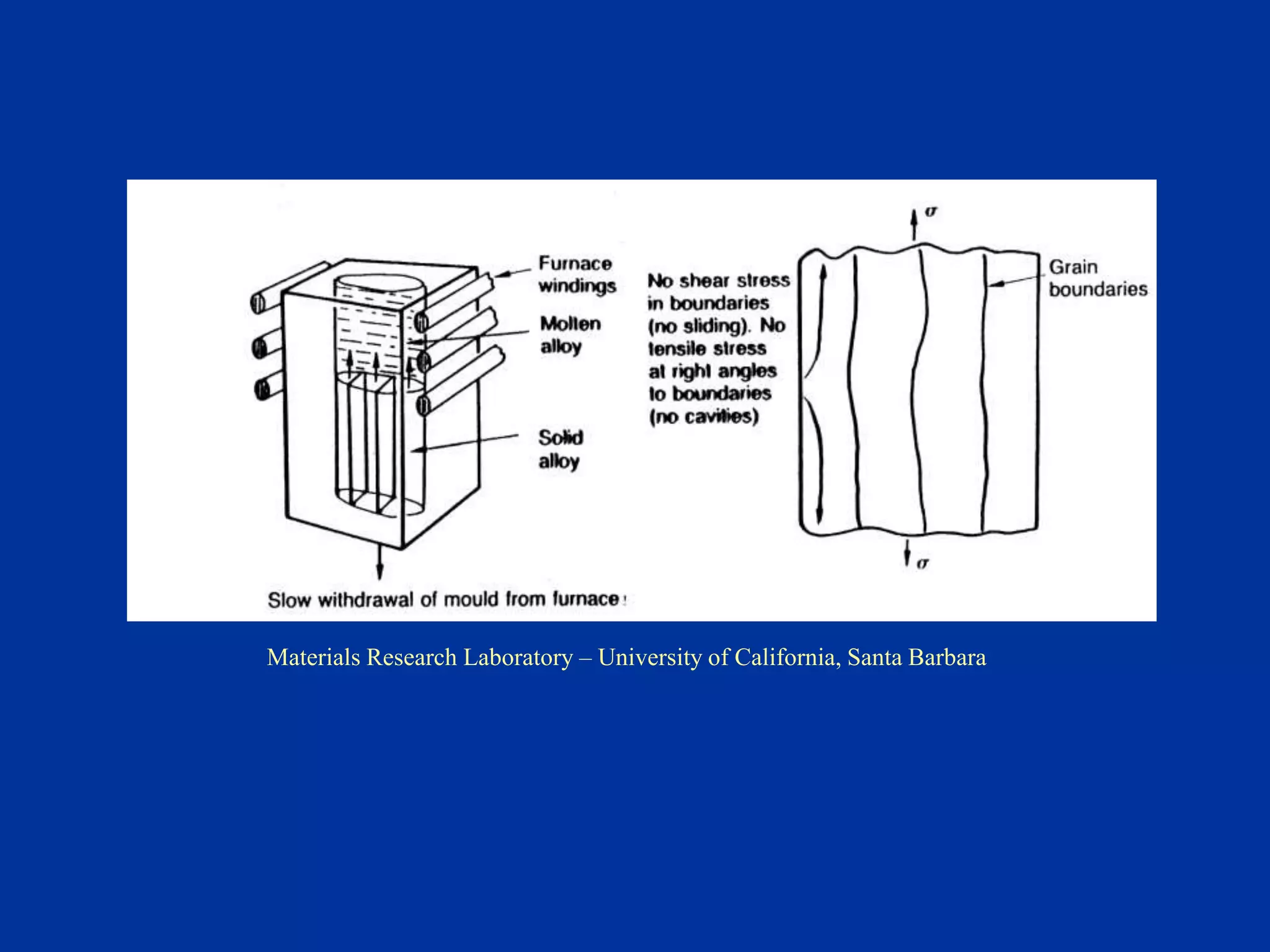

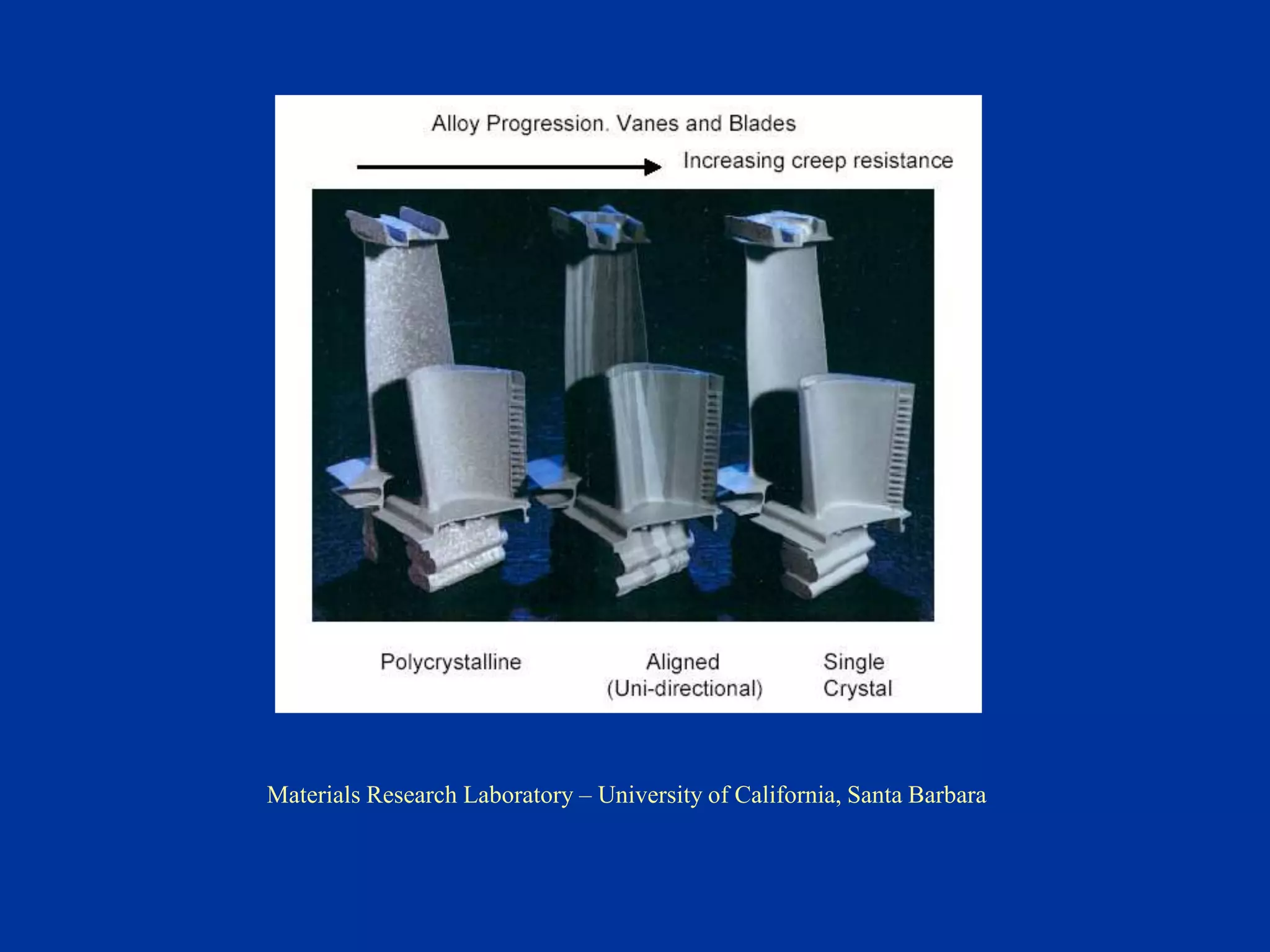

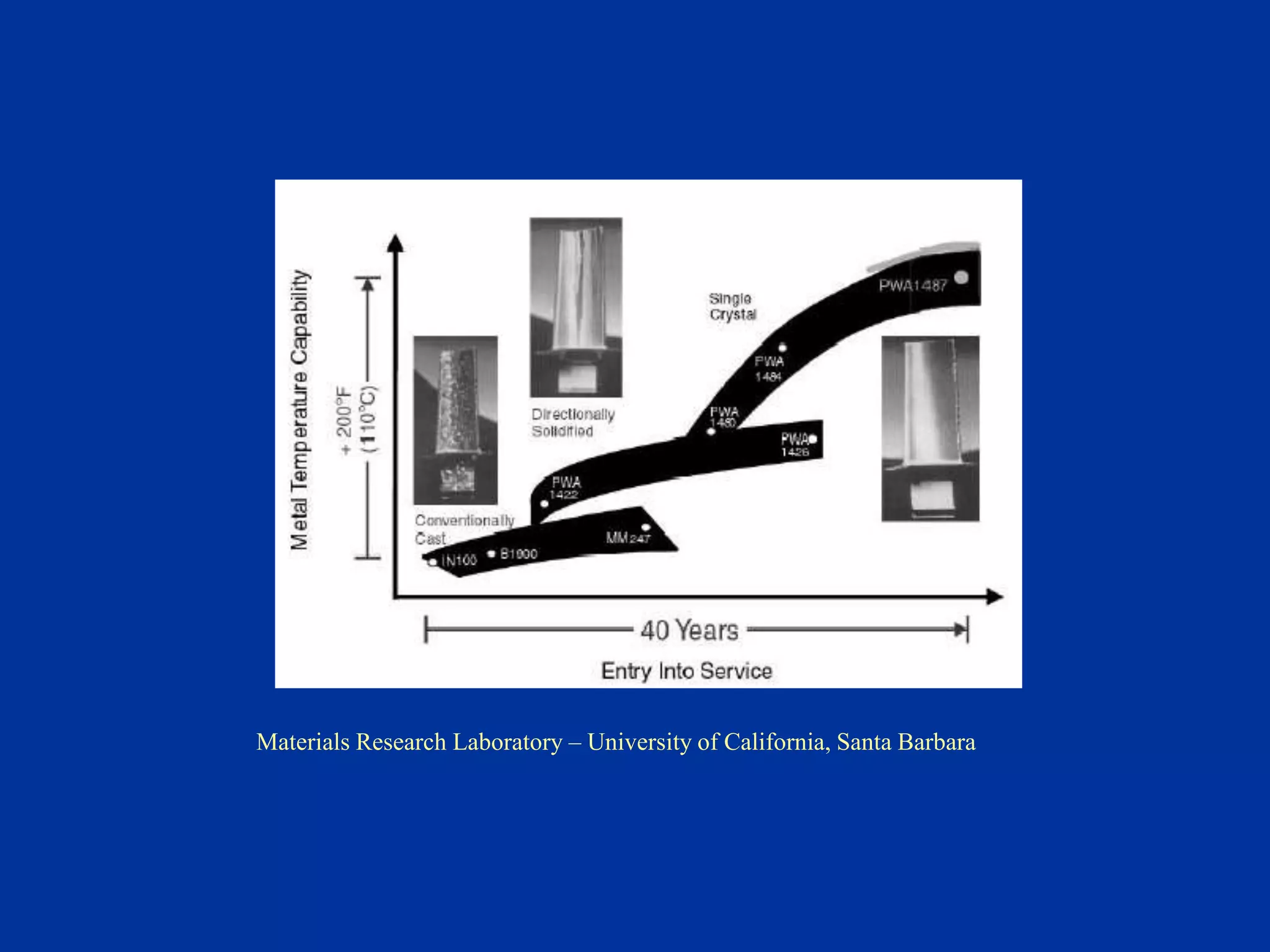

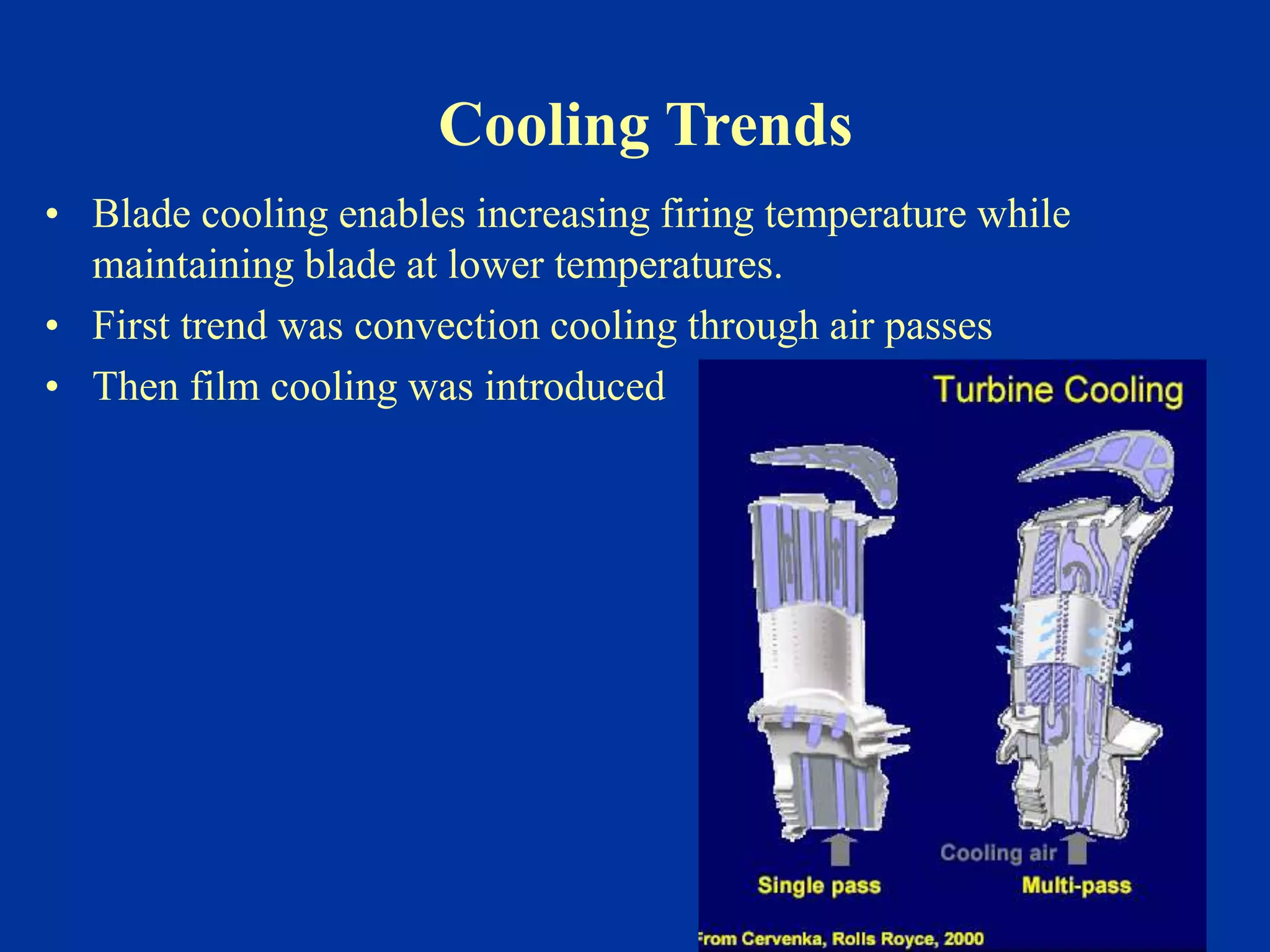

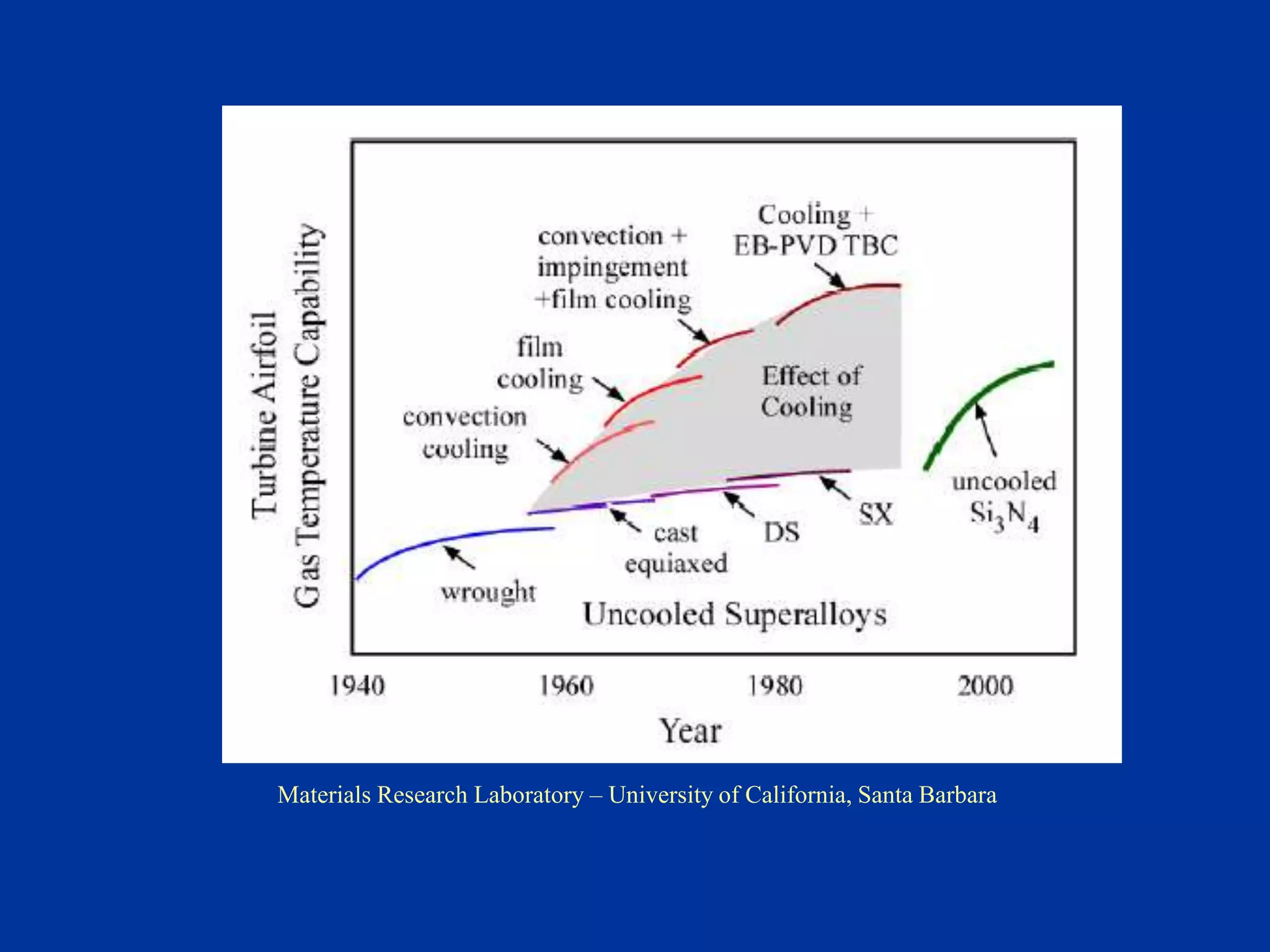

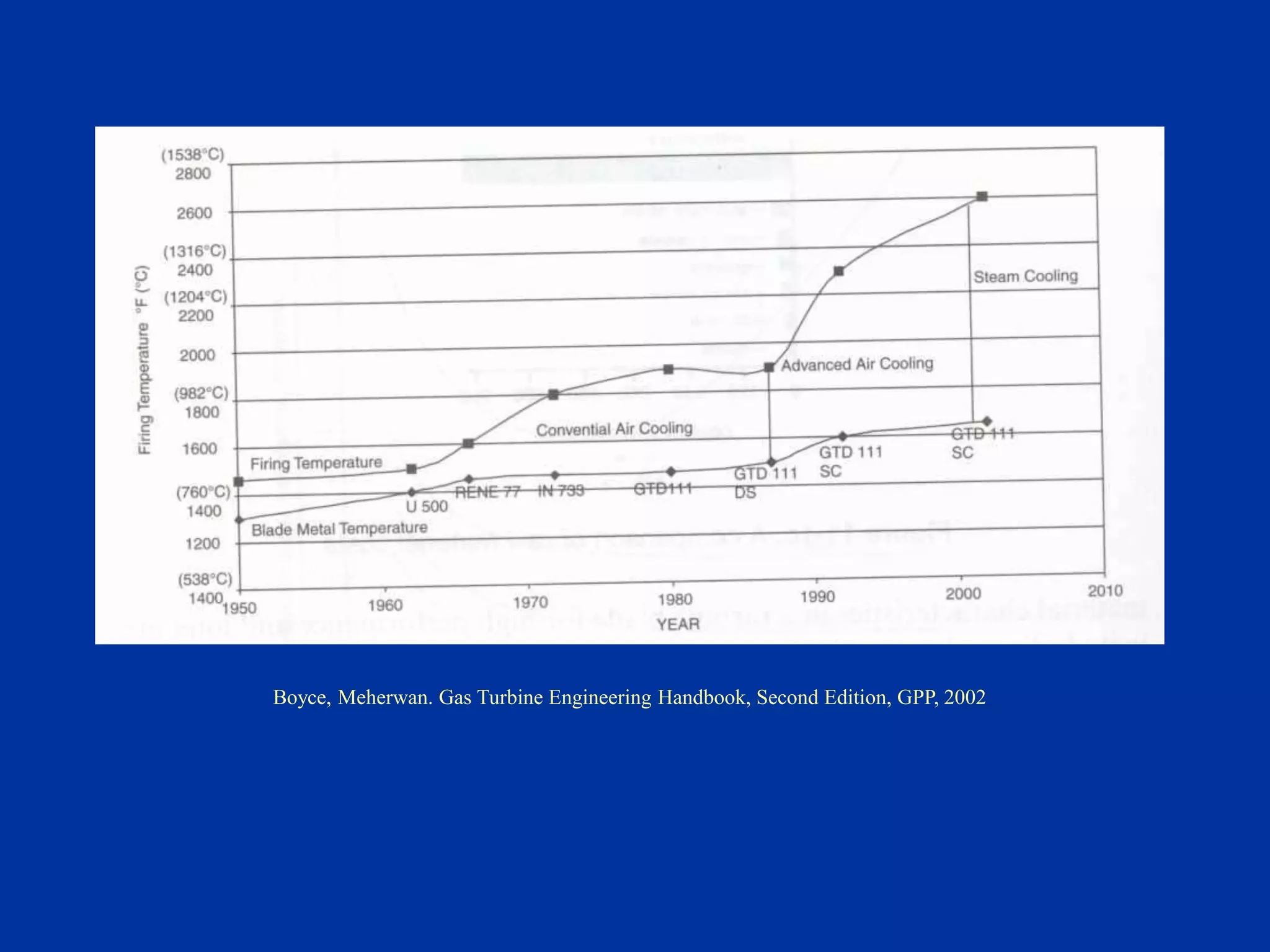

The document summarizes the development of materials for gas turbine and jet engine turbine blades. It discusses how earlier blades were made of steel but nickel-based superalloys were introduced in the 1940s as they had better high-temperature capabilities. It describes how wrought alloys were initially used but cast alloys became popular with advances in casting. It also outlines trends in processing like investment casting and directional solidification, and how cooling and coating technologies improved to allow higher firing temperatures.