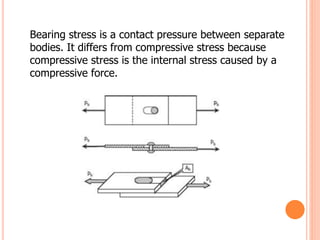

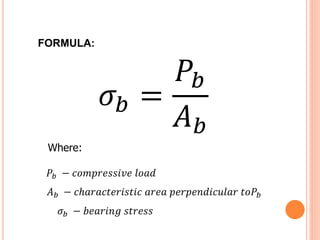

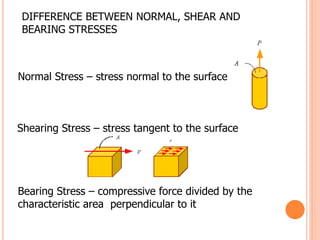

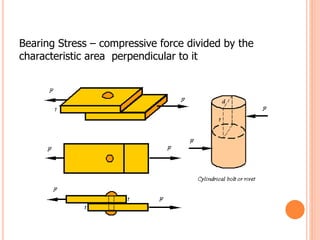

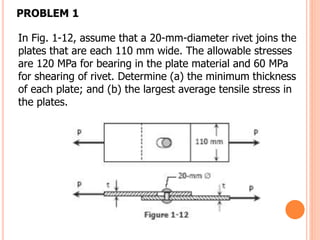

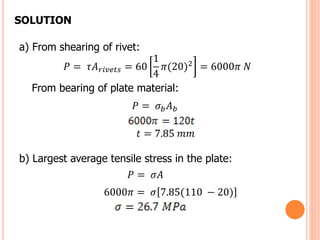

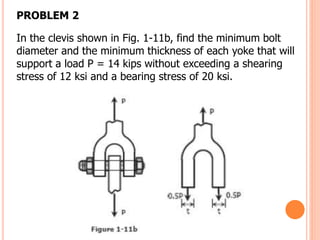

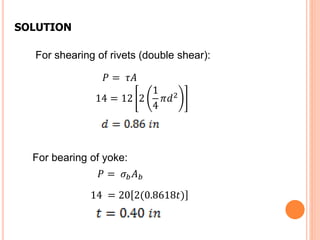

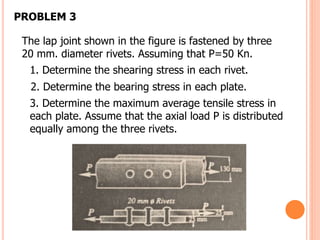

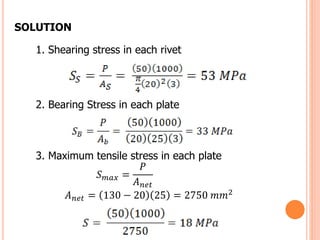

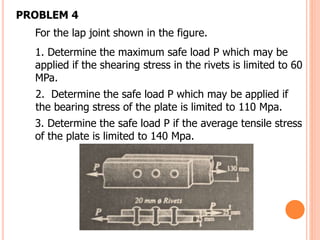

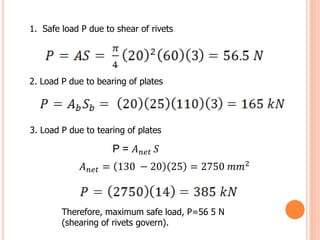

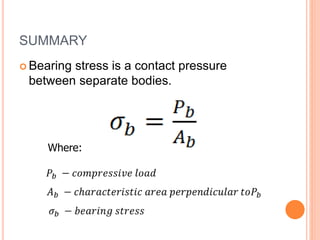

The document discusses bearing stress, detailing its definition as contact pressure between separate bodies, and differentiates it from compressive stress. It provides formulas for calculating bearing stress and presents examples to solve related problems involving shear and tensile stress. Additionally, it references two textbooks on mechanics of materials for further study.