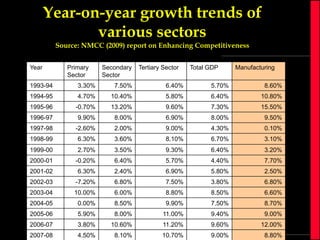

This document summarizes findings from multiple national manufacturing surveys conducted in India between 1997 and 2007. Some key findings include:

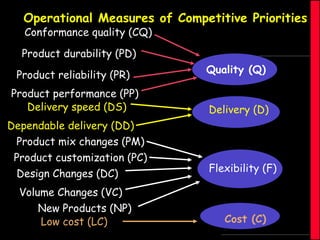

1) Early Indian manufacturing firms focused on quality but were opportunistic rather than strategic. Supply chains were fragmented.

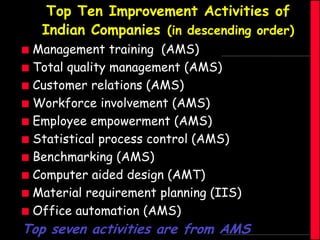

2) Later surveys found more focus on productivity and continuous improvement, but low investment in R&D and innovation. Quality remained the top priority.

3) The 2007 survey found regional differences in capabilities. Smaller firms focused more on customization while medium firms showed most potential for competitiveness. Skill development and supply chain coordination were major needs.