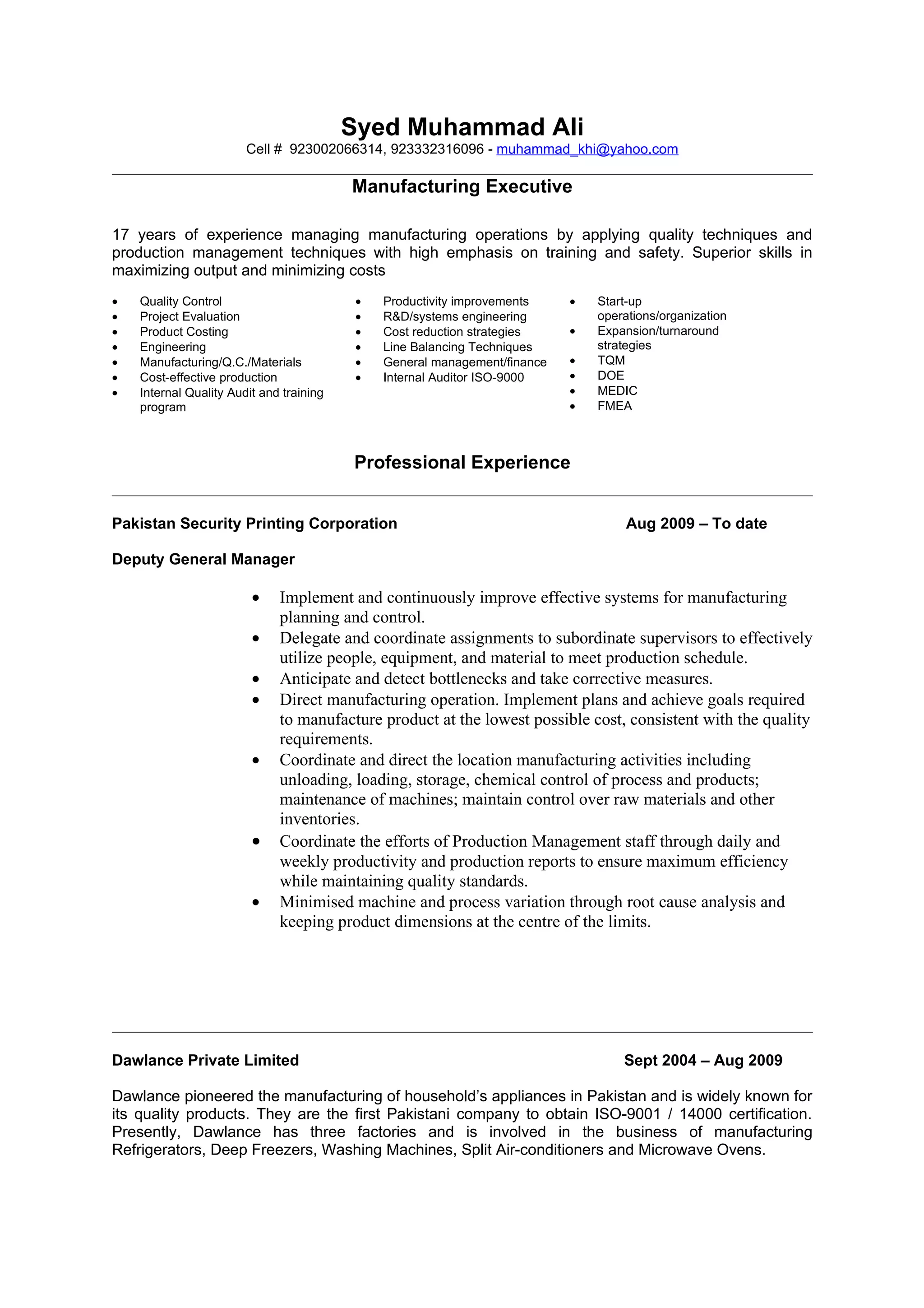

Syed Muhammad Ali has over 17 years of experience in manufacturing operations and production management. He has held roles such as Factory Manager and Deputy General Manager at various companies. He specializes in quality control, productivity improvements, cost reduction strategies, and safety training programs. He has experience implementing manufacturing systems, optimizing output while minimizing costs, and ensuring compliance with ISO standards.