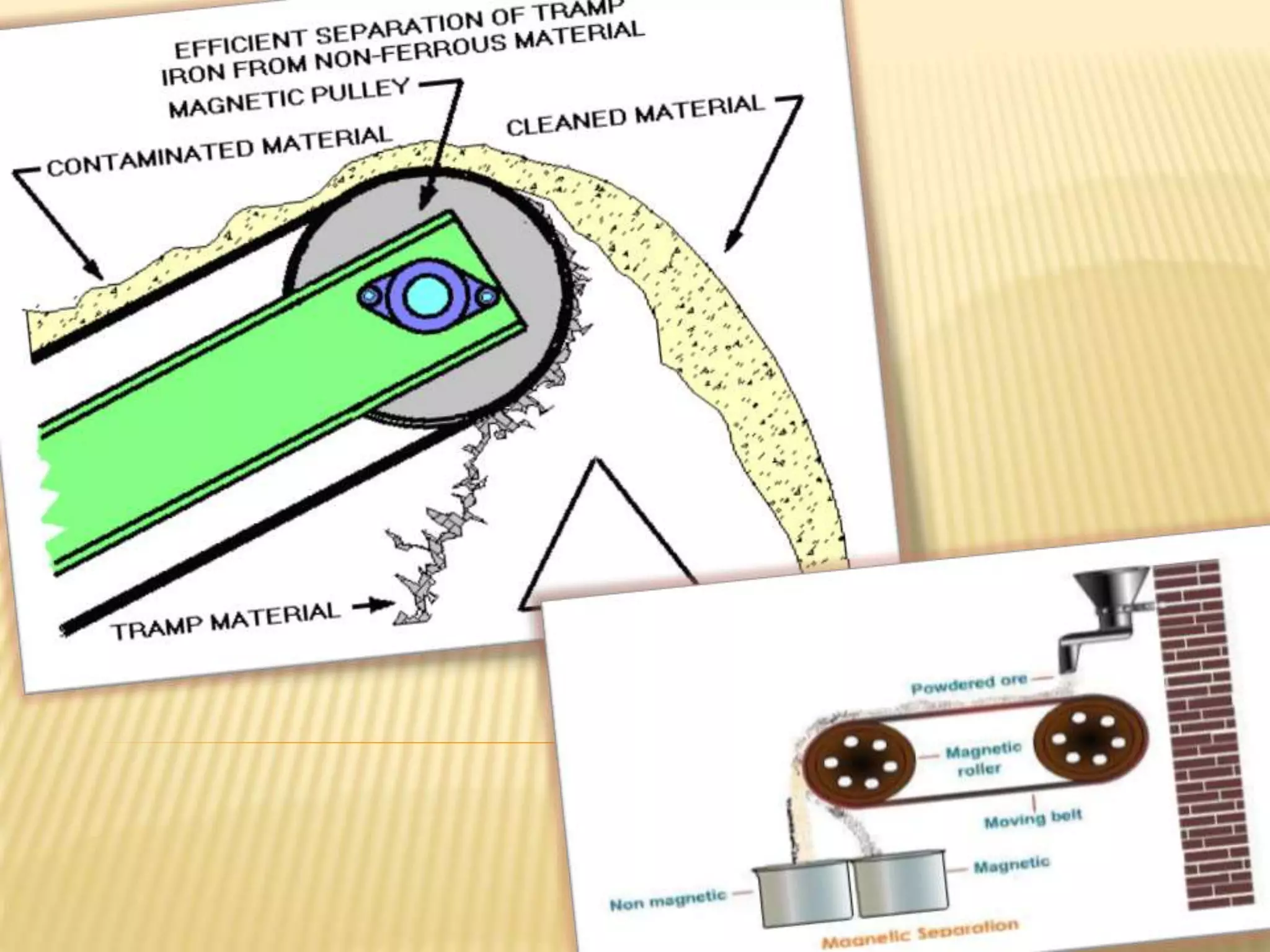

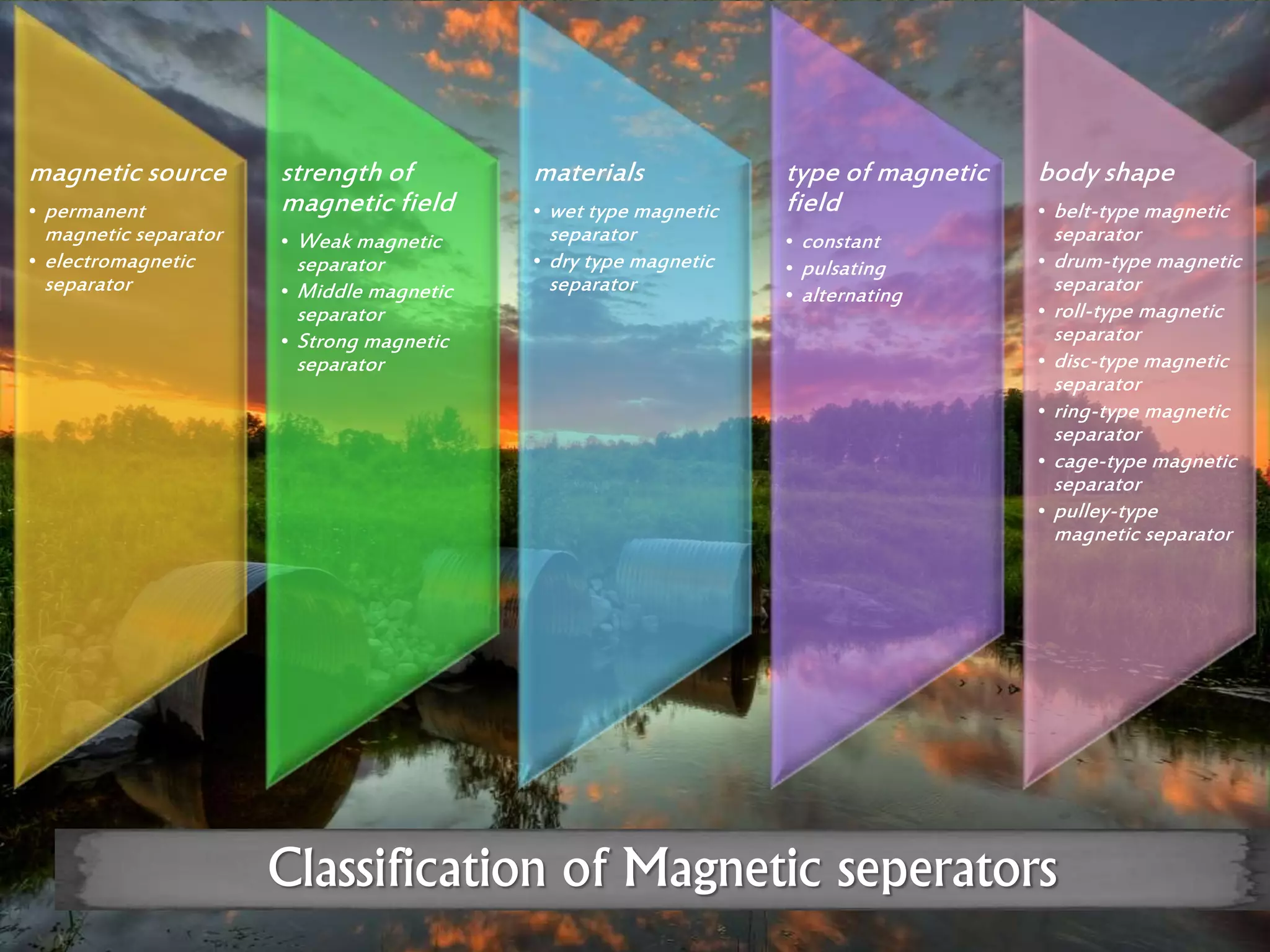

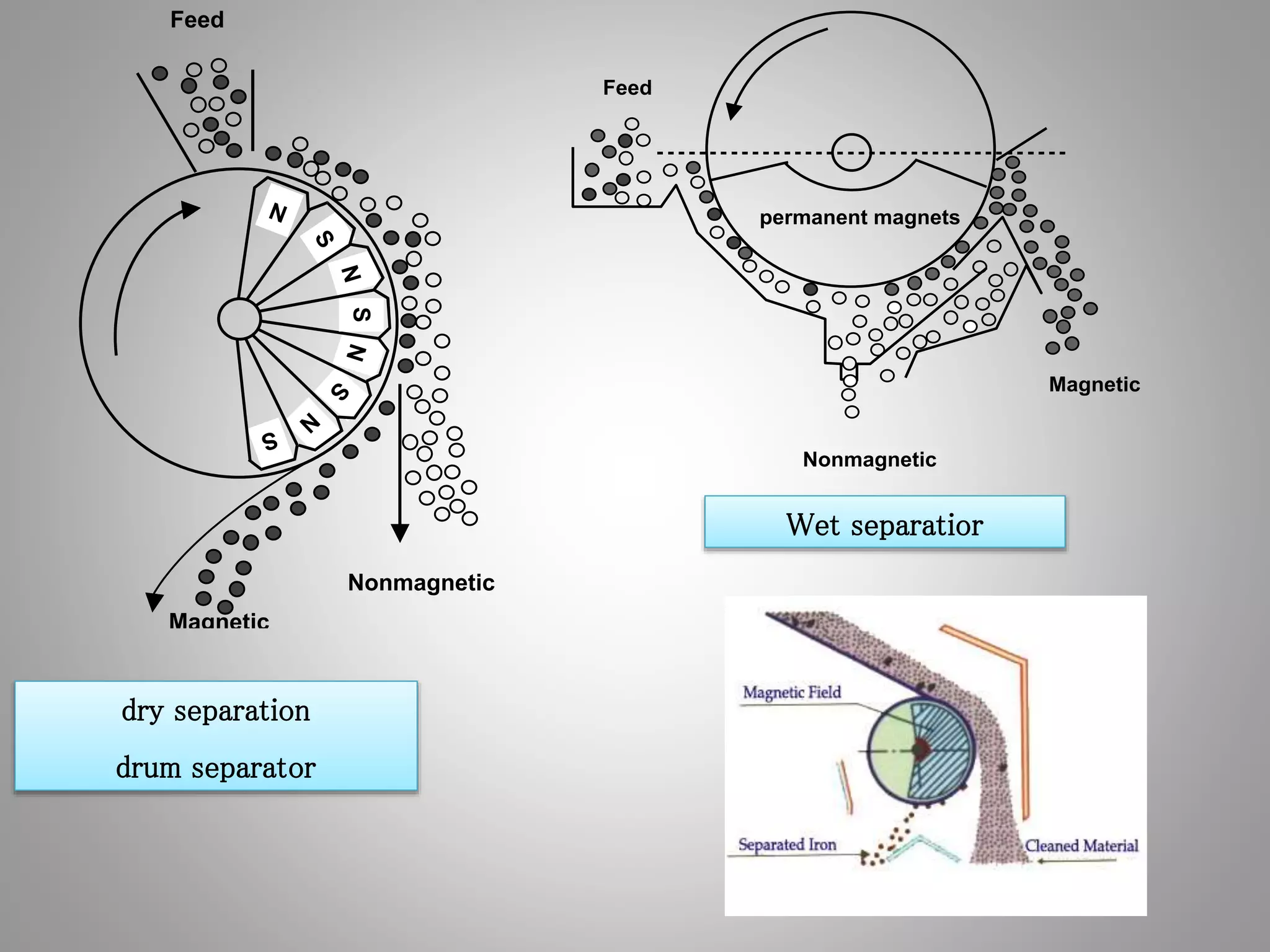

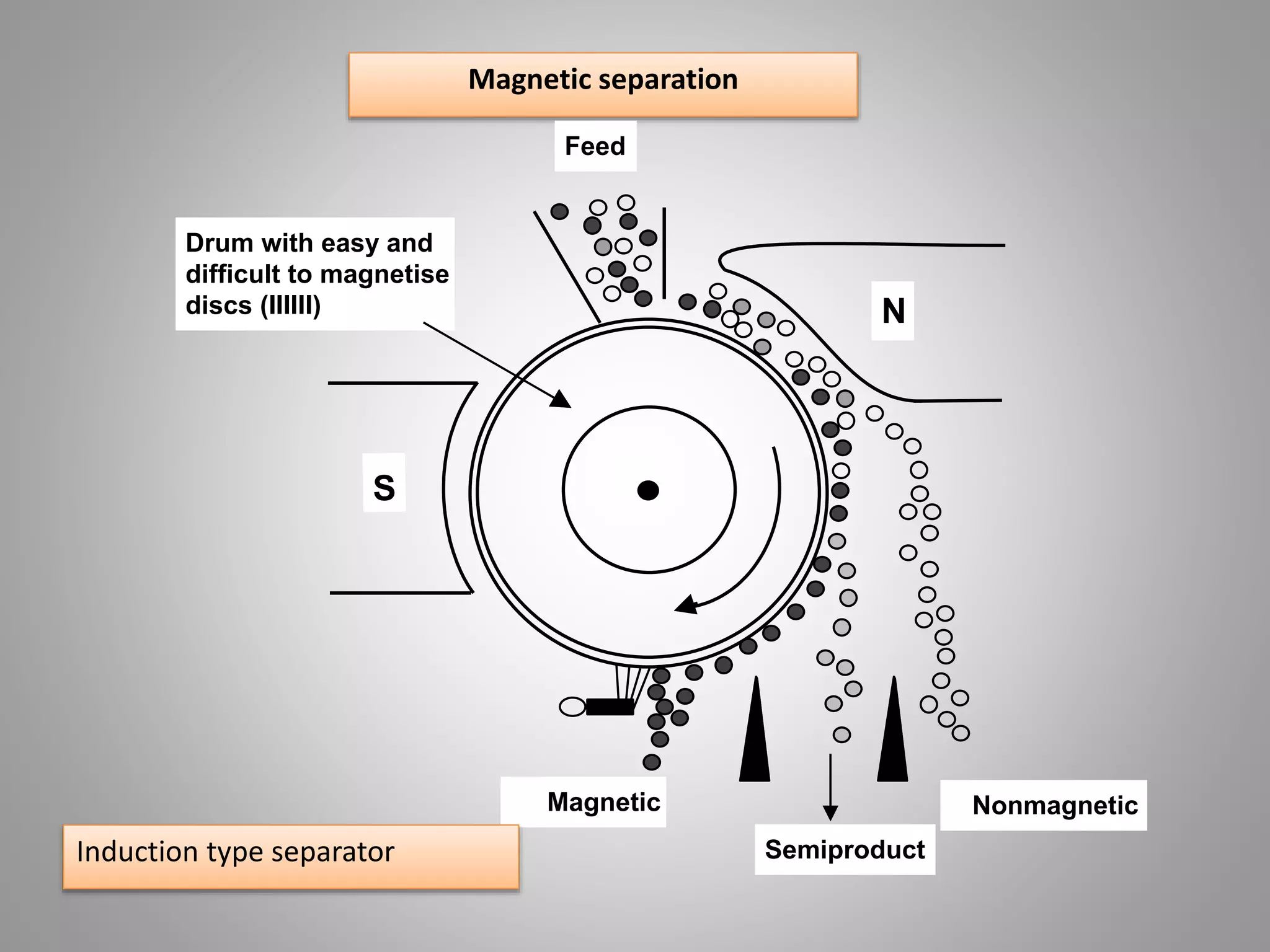

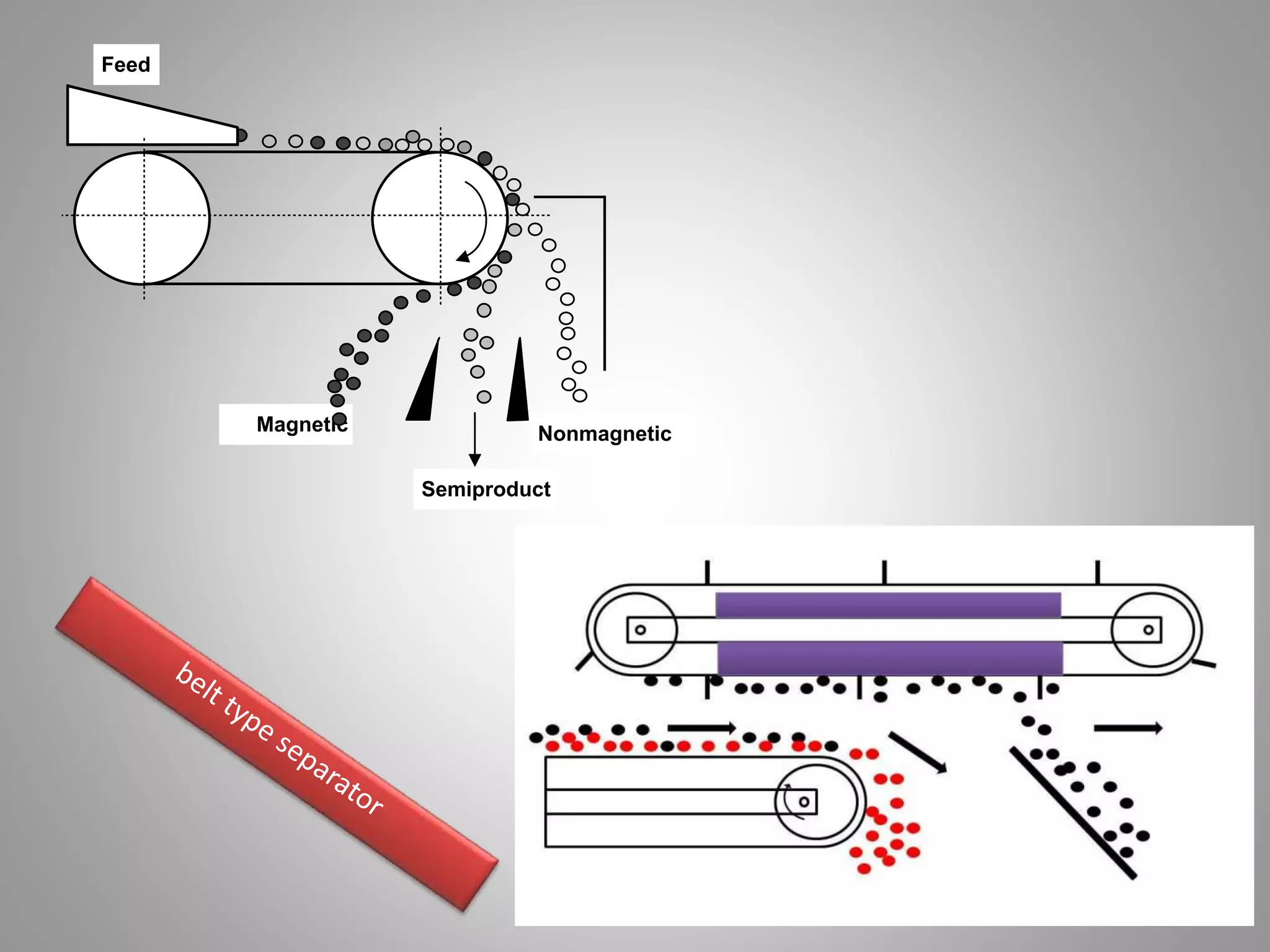

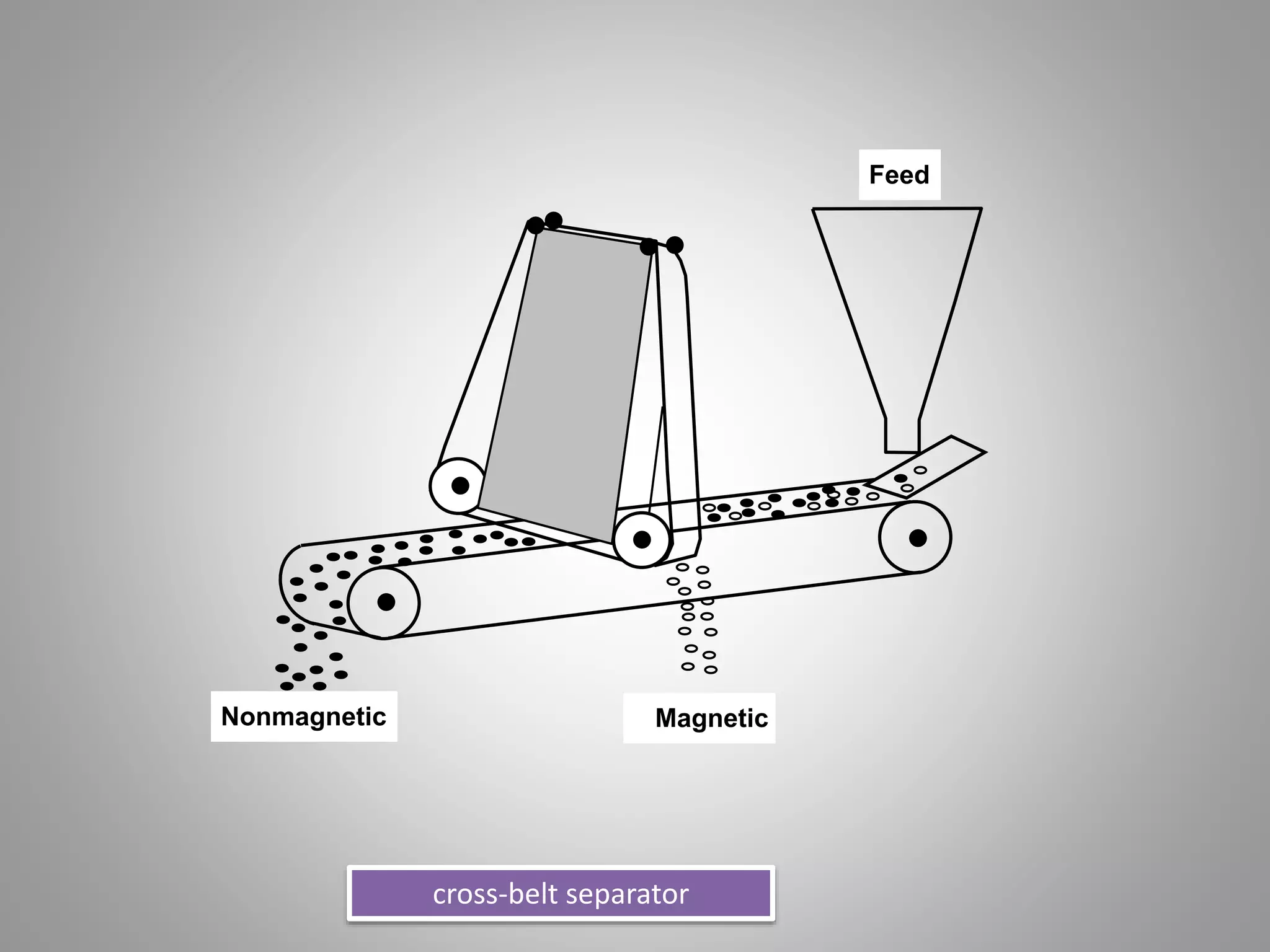

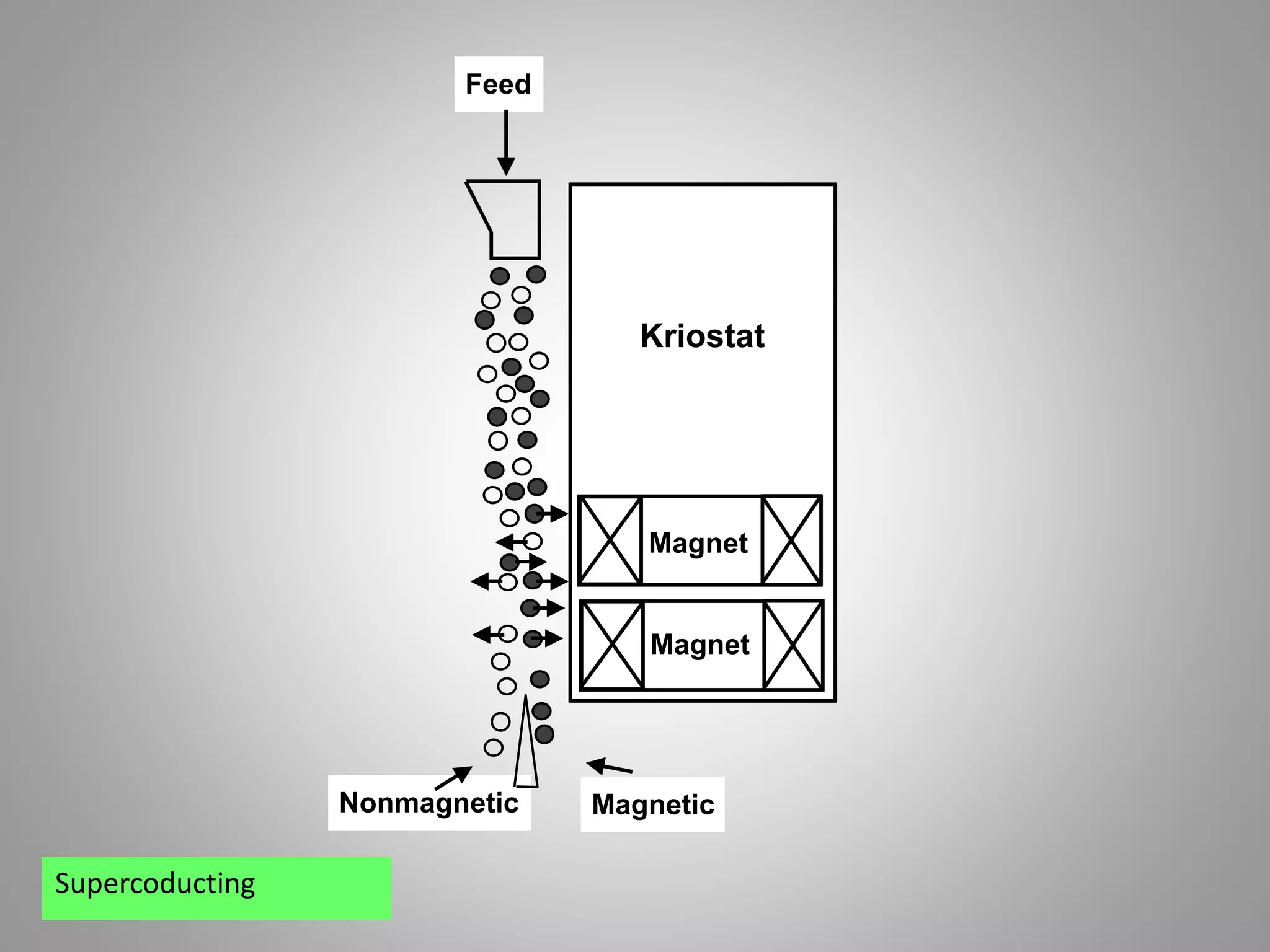

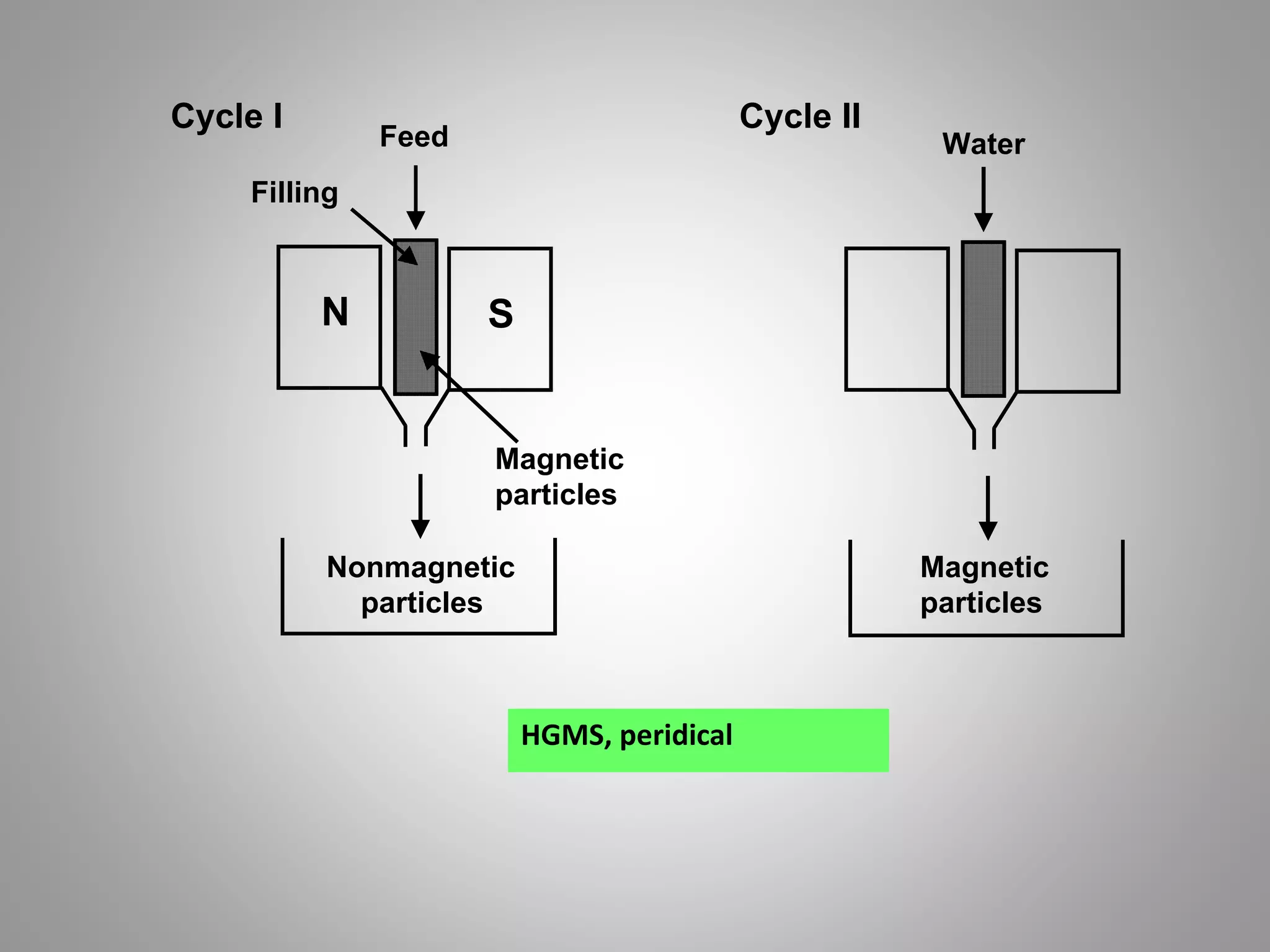

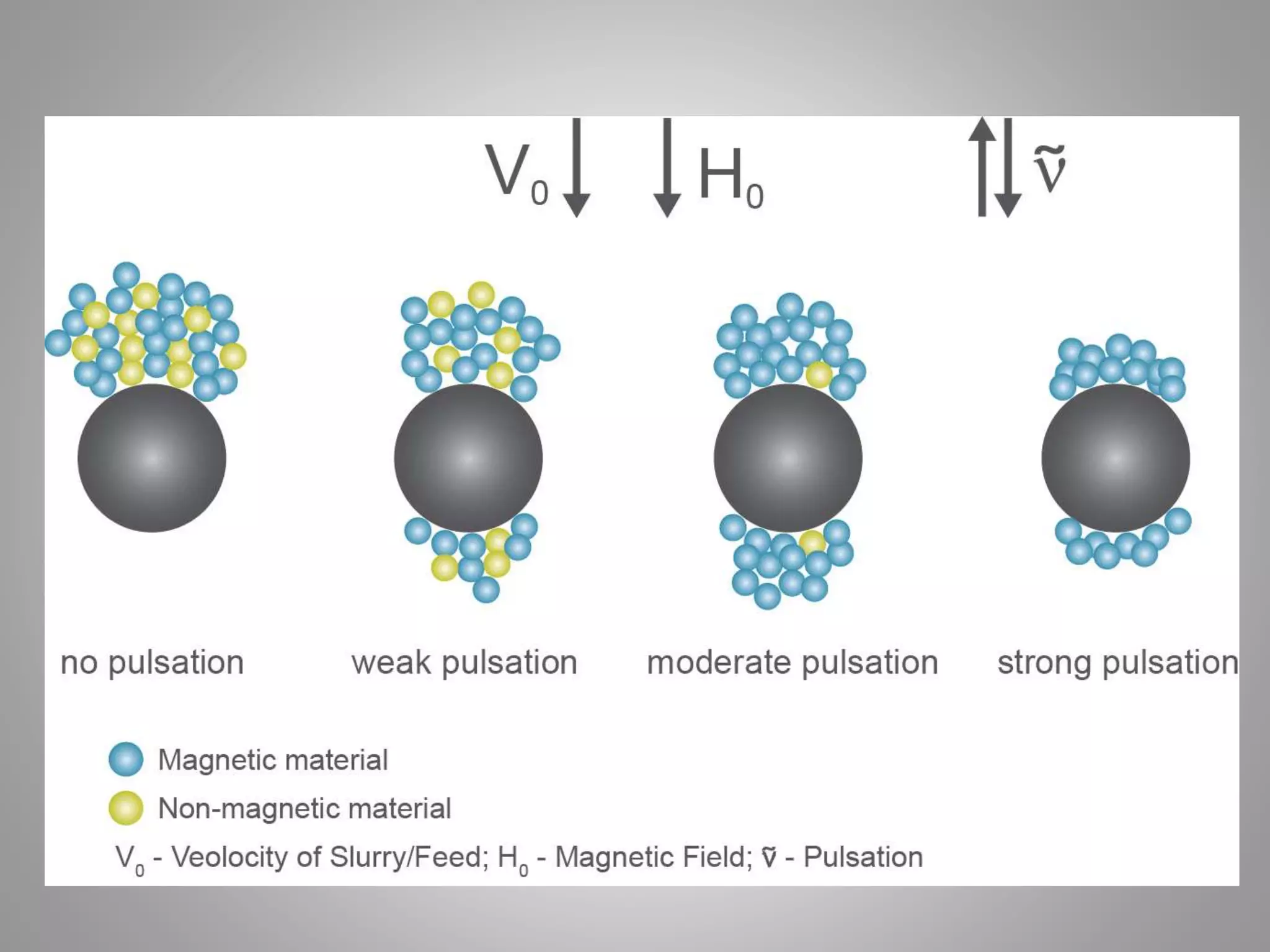

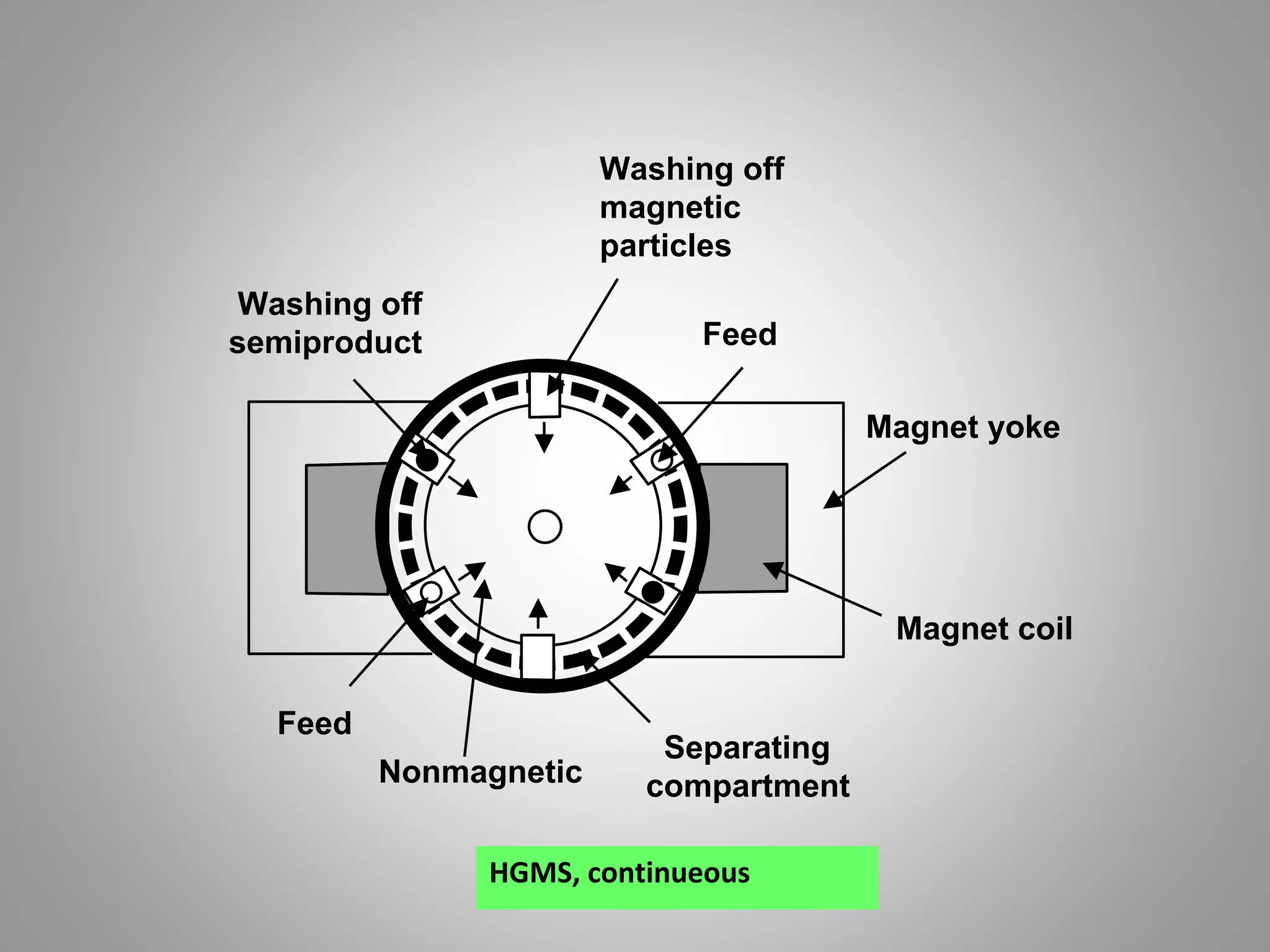

This document discusses various methods for separating mixtures, with a focus on magnetic separation. It provides an overview of different types of magnetic separators and how they work. The key methods mentioned include using magnetism to separate magnetically susceptible materials, concentrating ores containing iron or other magnetic minerals, and separating slightly paramagnetic minerals. The document also classified magnetic separators based on their magnetic source, field strength, materials, field type, body shape and other characteristics.