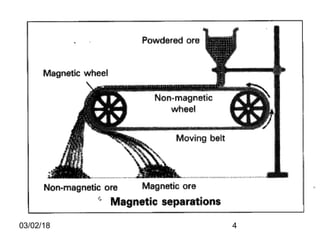

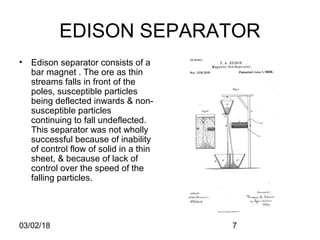

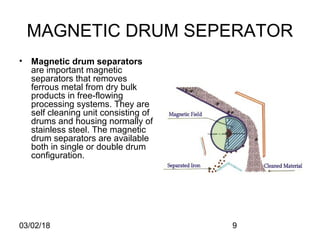

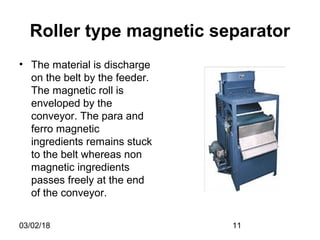

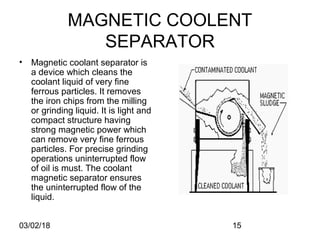

This document summarizes different types of magnetic separators. It describes Edison, Ball Norton, magnetic drum, roller type, gravity feed, and magnetic coolant separators. Magnetic separation is a process that uses magnetic force to separate magnetically susceptible material from a mixture. Various industries such as glass, ceramic, chemical, fertilizer, plastic, food, mining, and pharmaceuticals use different types of magnetic separators to separate ferrous metals from dry or liquid products.