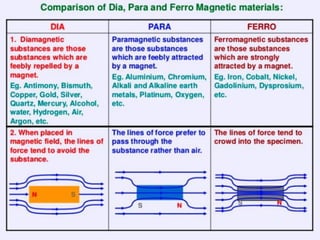

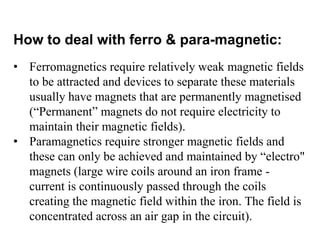

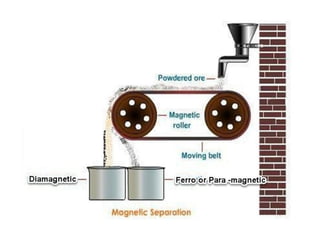

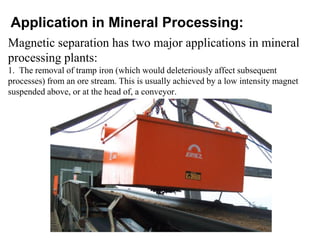

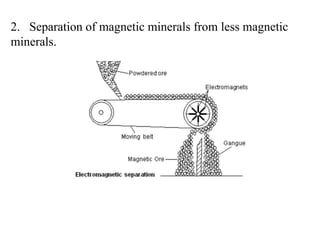

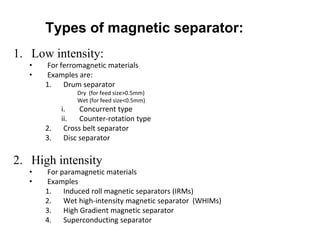

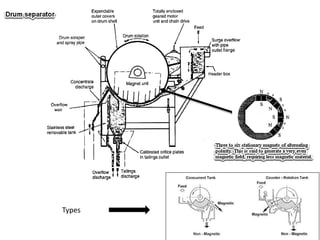

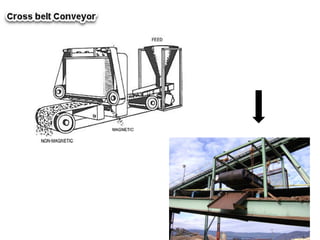

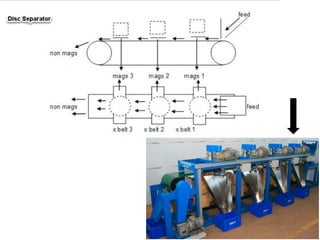

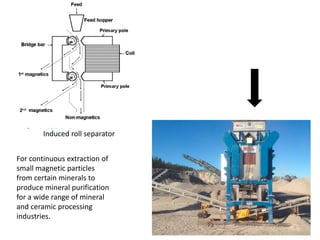

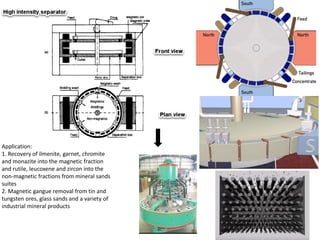

Magnetic separation is a process that uses magnets to separate ferromagnetic and paramagnetic materials from other materials. Ferromagnetic materials require relatively weak magnetic fields and are typically separated using permanent magnets, while paramagnetic materials require stronger magnetic fields that can only be produced by electromagnets. Magnetic separation has applications in mineral processing, such as removing tramp iron from ores or separating magnetic minerals from less magnetic ones. There are different types of magnetic separators suited to various materials and particle sizes, including drum separators, cross belt separators, and high-intensity separators used for paramagnetic materials.