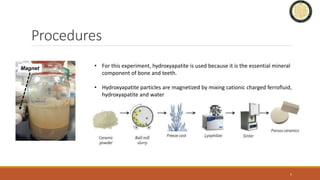

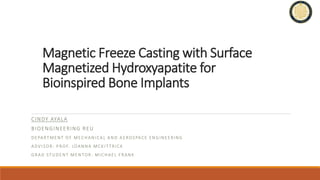

This document discusses research into using magnetic freeze casting to create porous hydroxyapatite scaffolds for bone implants. Hydroxyapatite particles are magnetized and freeze cast into aligned structures that mimic bone's trabecular structure. Testing shows 20% hydroxyapatite slurries frozen with a 25mT magnetic field produce scaffolds with the highest porosity and particle chain alignment in the center. Future work will reinforce the scaffolds and test them as potential implants for treating osteoporosis.

![Motivation

Osteoporosis

- causes erosion of trabecular (spongy) bone

- leads to decreased bone mass, especially in the elderly

- results in brittle bones that lead to unexpected failure

- titanium implants can lead to stress shielding

(reduction in bone density due to removal of stress from

bone by the implant)

- titanium implants often require adjustment surgeries

2

[1] http://www.medguidance.com/thread/What-Causes-Osteoporosis.html

Goal

Create a porous scaffold made of bone

mineral which mimics the structure of bone](https://image.slidesharecdn.com/cc9e1d55-aff2-44ac-b49b-e9f51ddce4a0-161130021013/85/Magnetic-Freeze-Casting-Presentation-2-320.jpg)