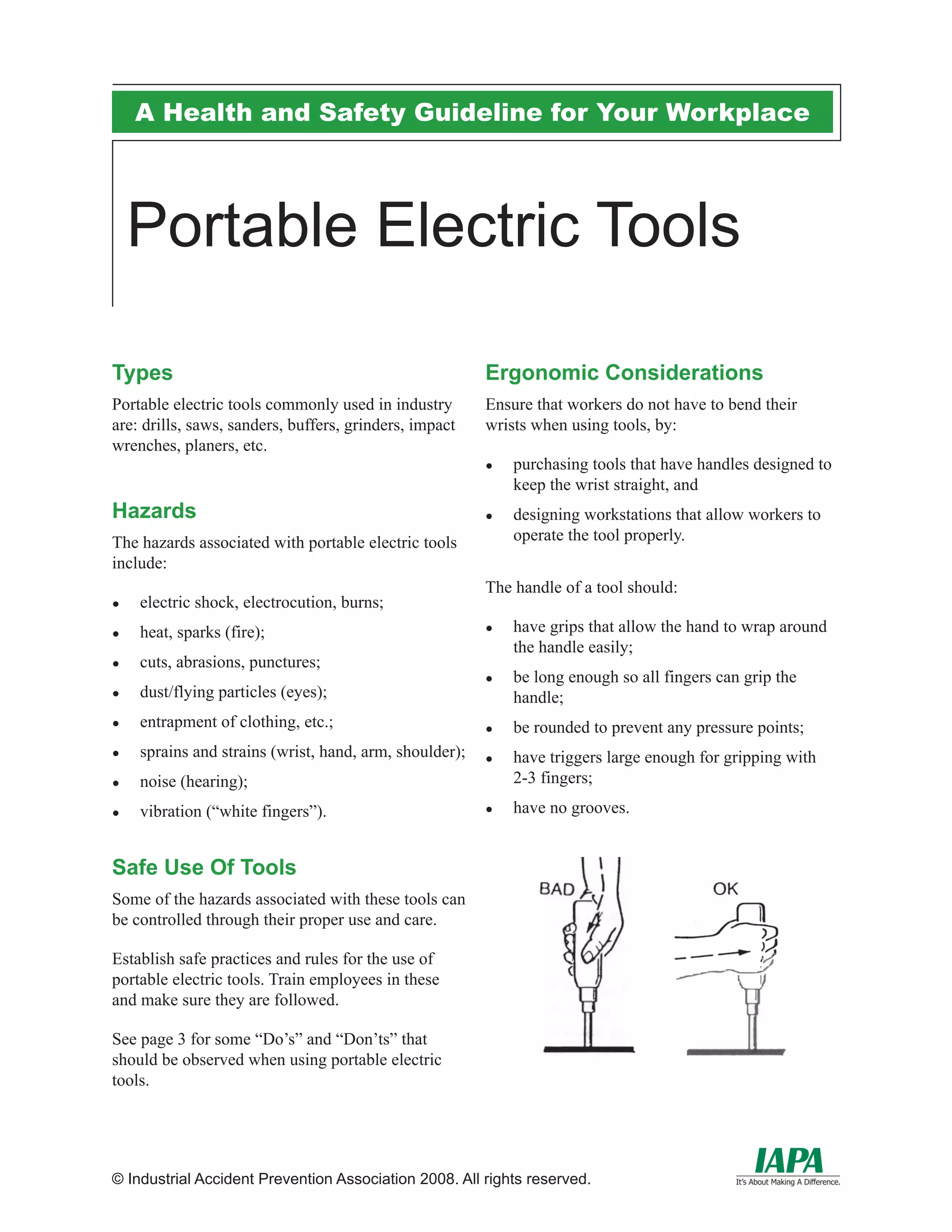

Portable electric tools are commonly used in industry and present several hazards if not properly used and maintained. These hazards include electric shock, cuts, burns, dust/particles, noise, and vibration. To reduce risks, employers should provide training on safe tool use, select ergonomic tools, and implement regular maintenance and inspection programs. Proper handling techniques and use of protective equipment can help control hazards from portable electric tools.