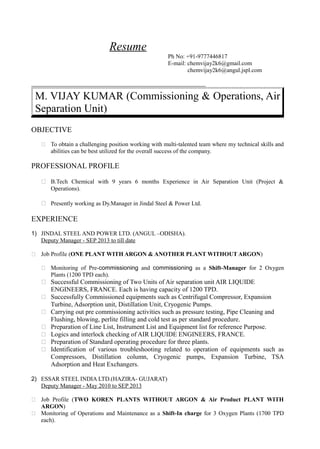

M. Vijay Kumar has 9 years of experience working in air separation units. He is currently a Deputy Manager at Jindal Steel & Power Ltd in Angul, Odisha, where he has helped commission two 1200 TPD oxygen plants. Prior to this, he worked at Essar Steel India Ltd, where he helped commission three 1700 TPD oxygen plants. He has a B.Tech in Chemical Engineering and skills in areas like process design, DCS operation, pre-commissioning, and equipment troubleshooting.