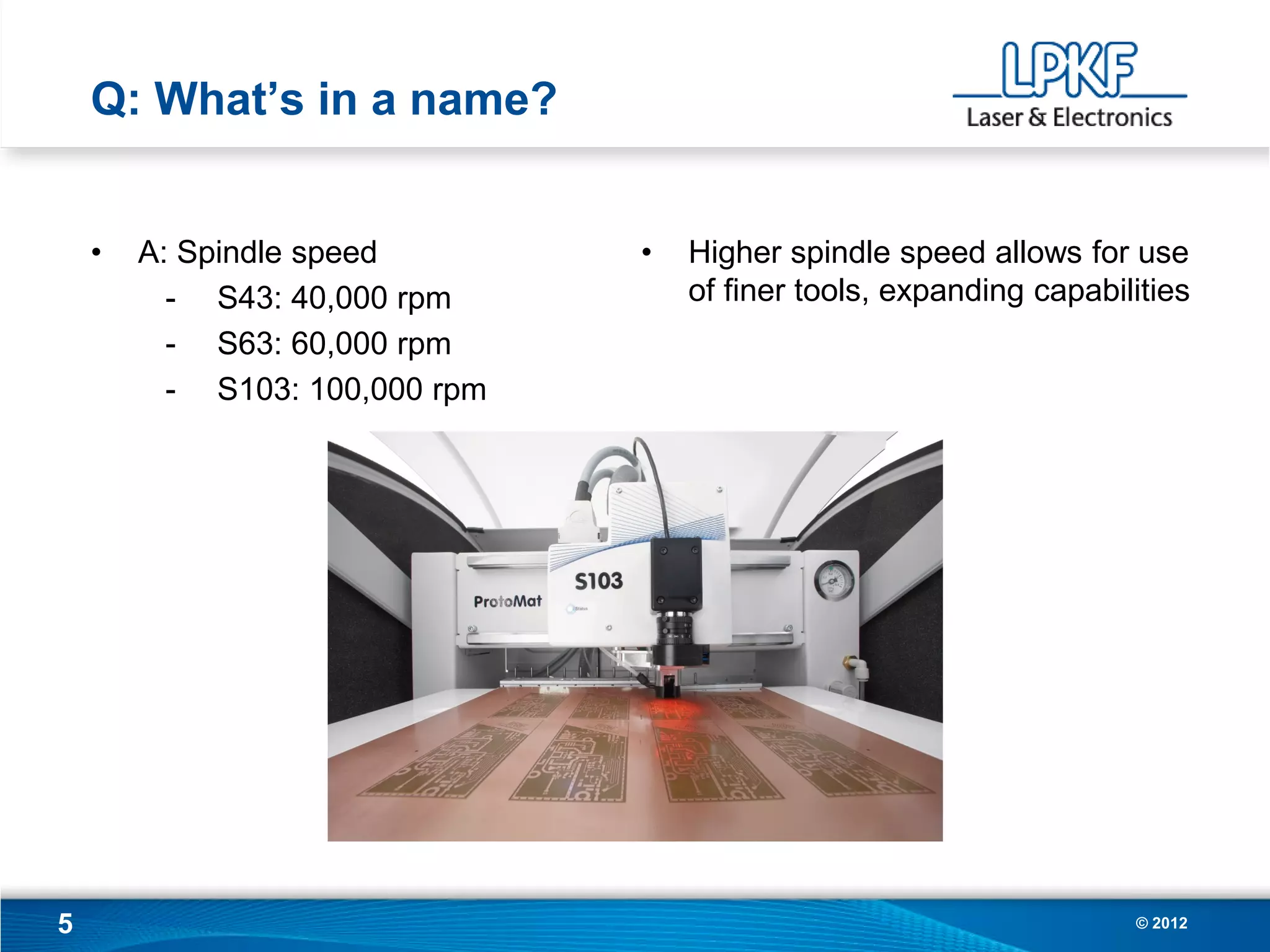

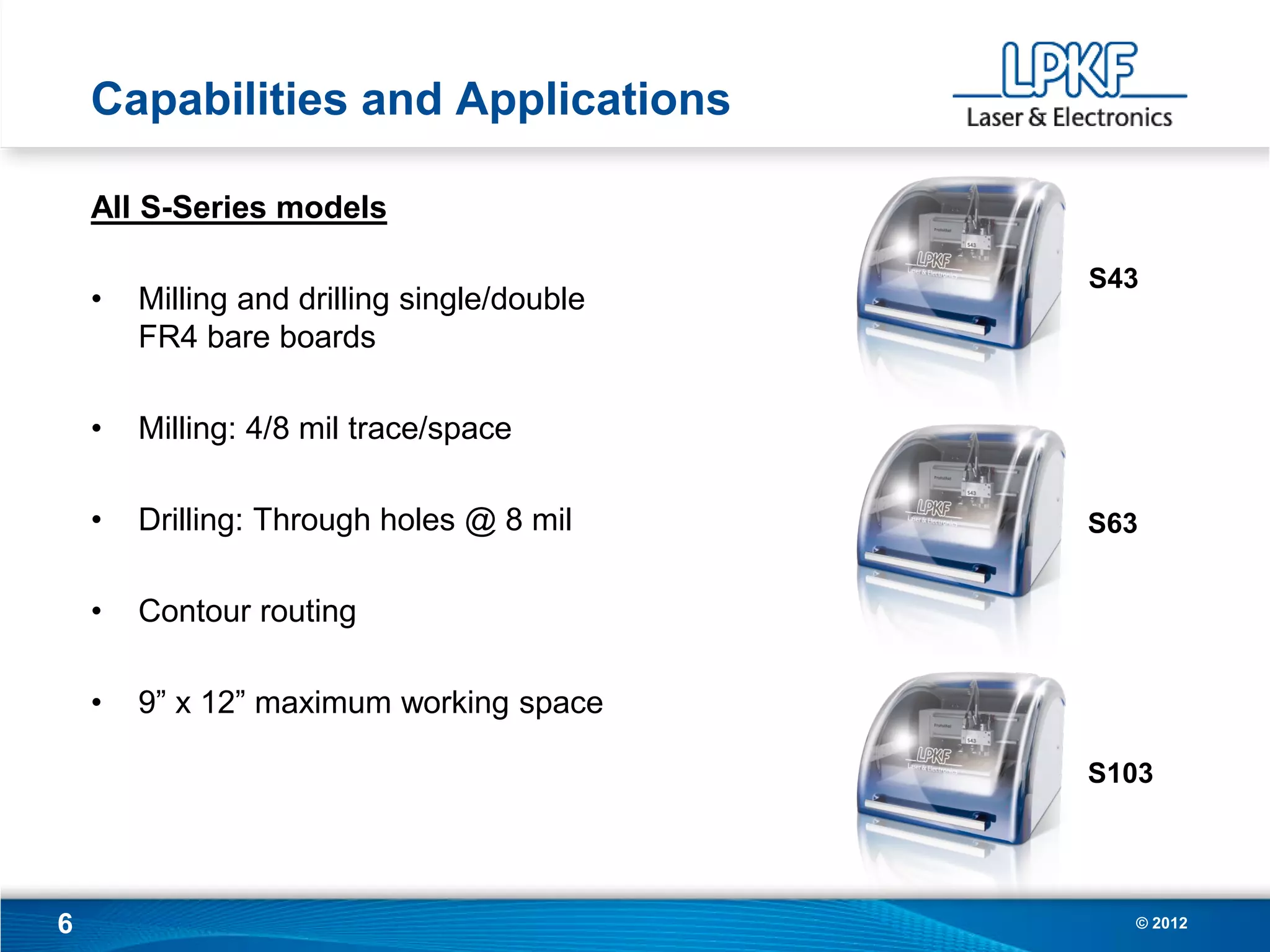

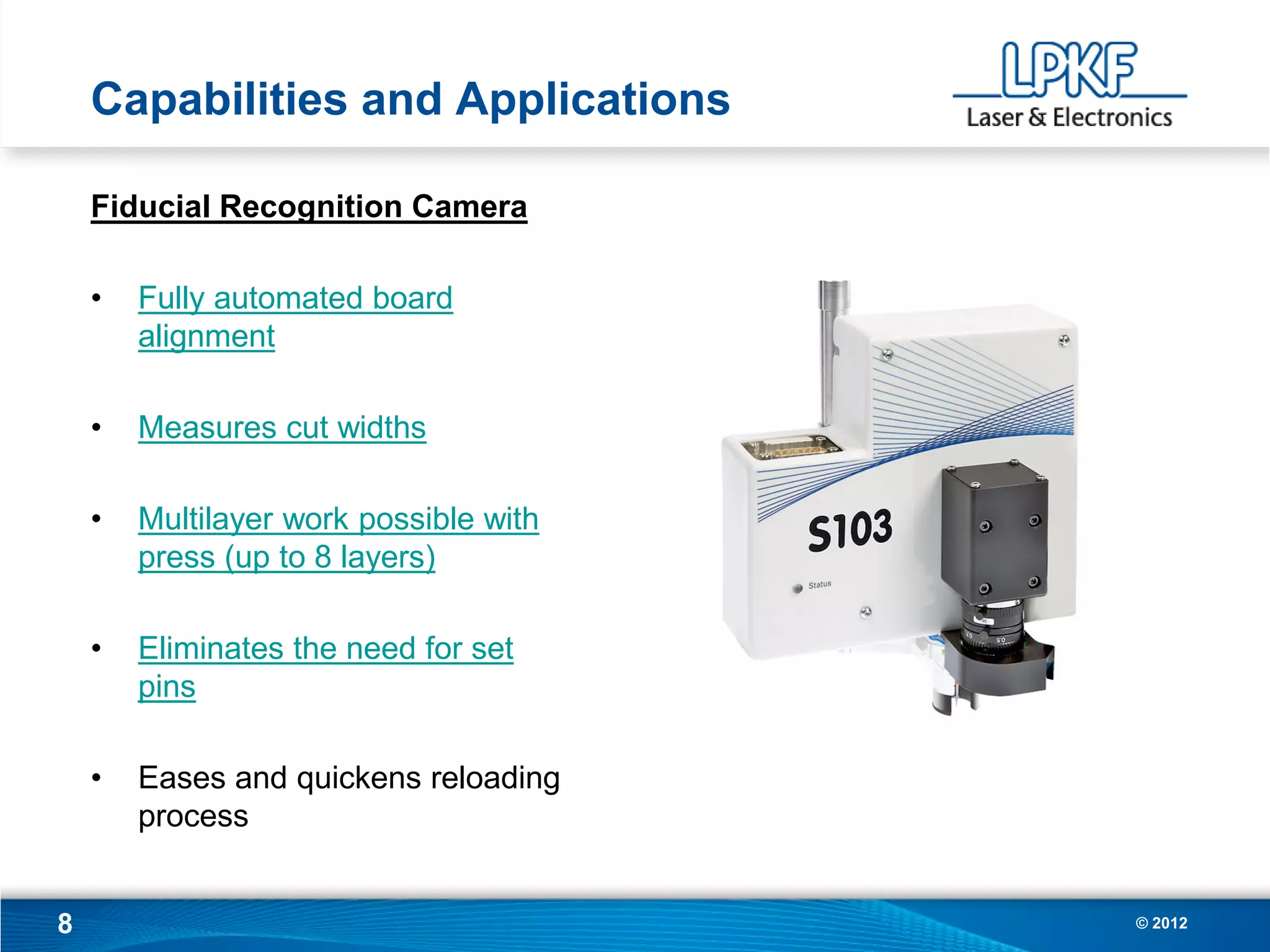

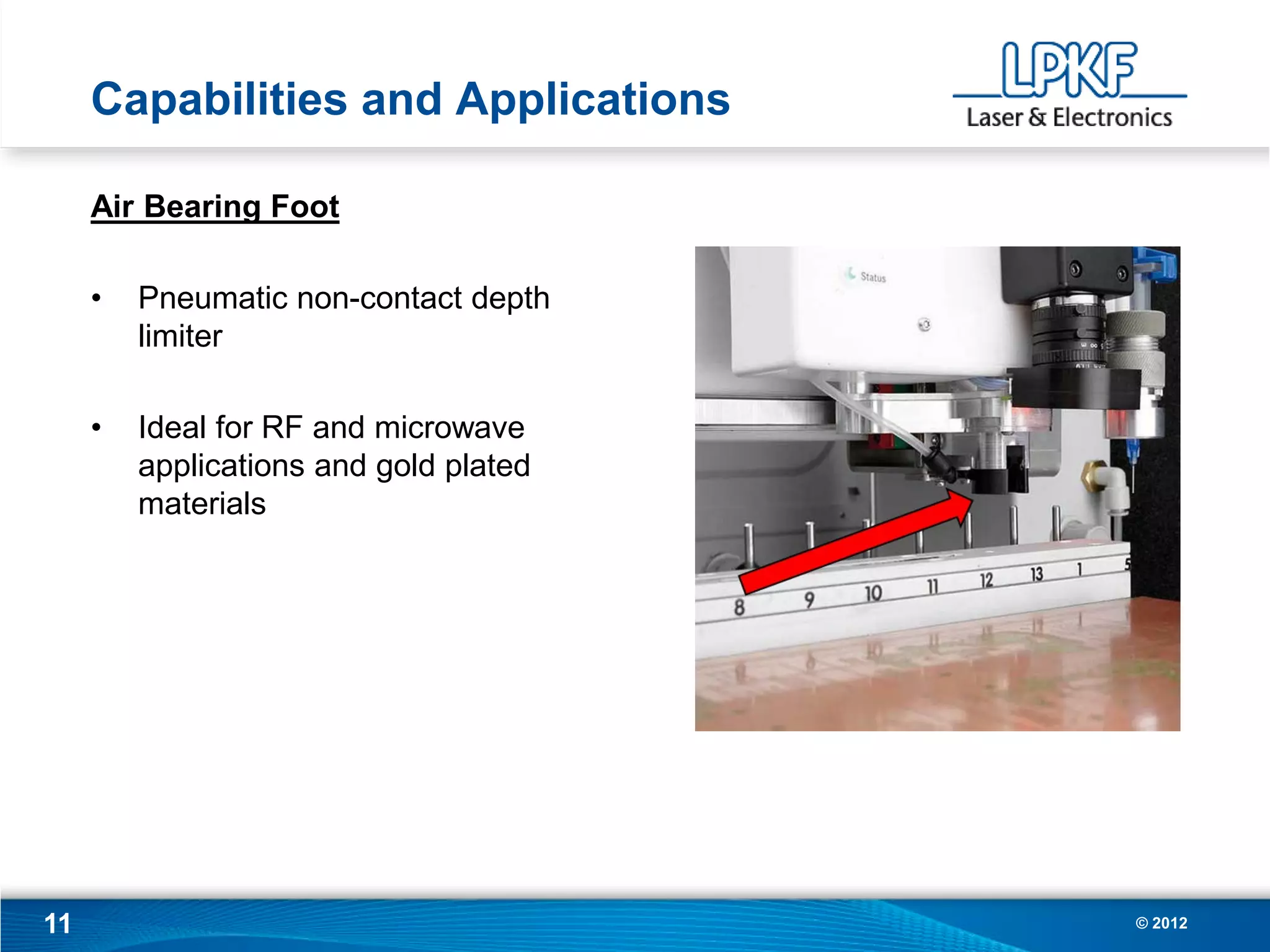

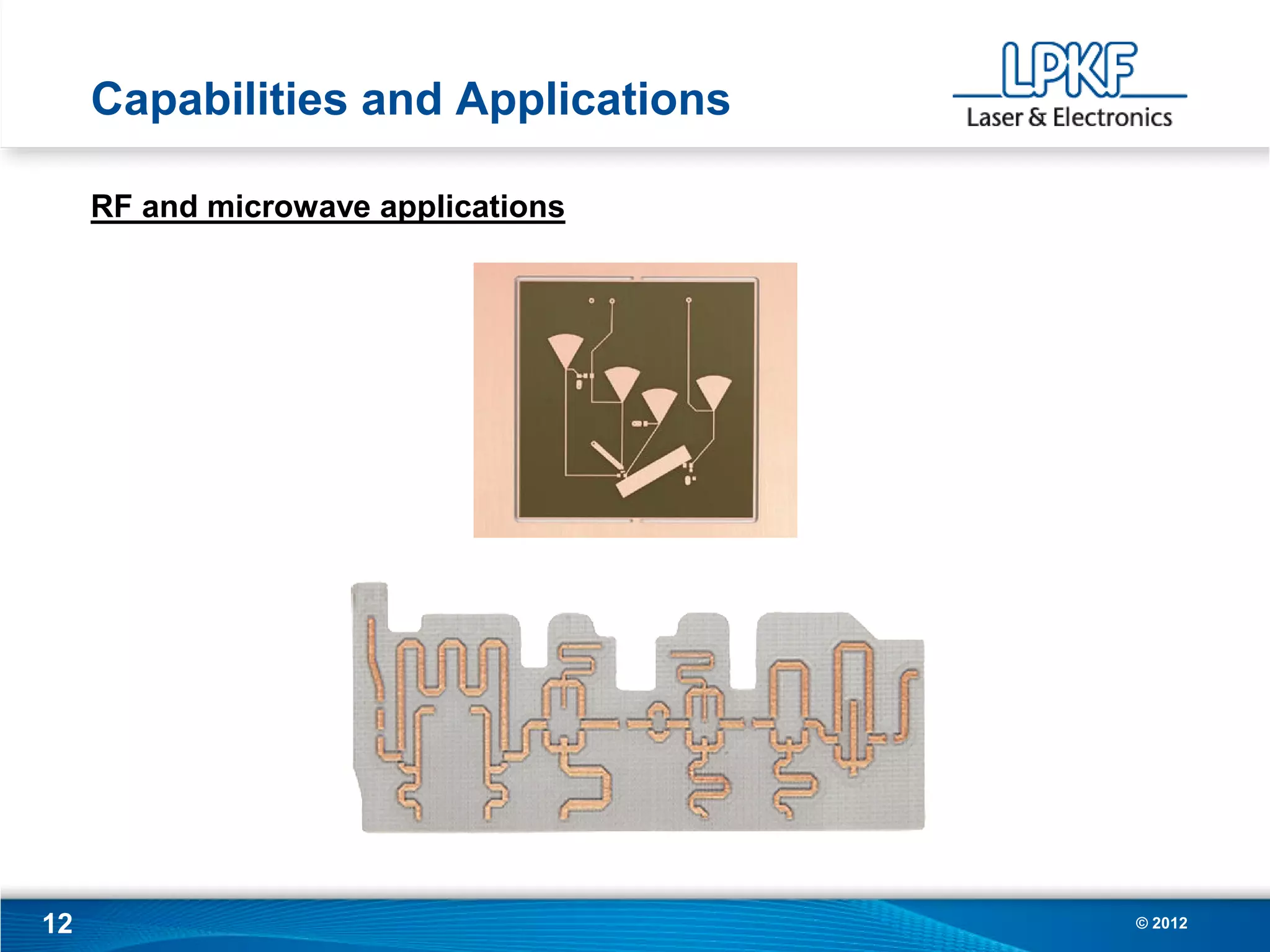

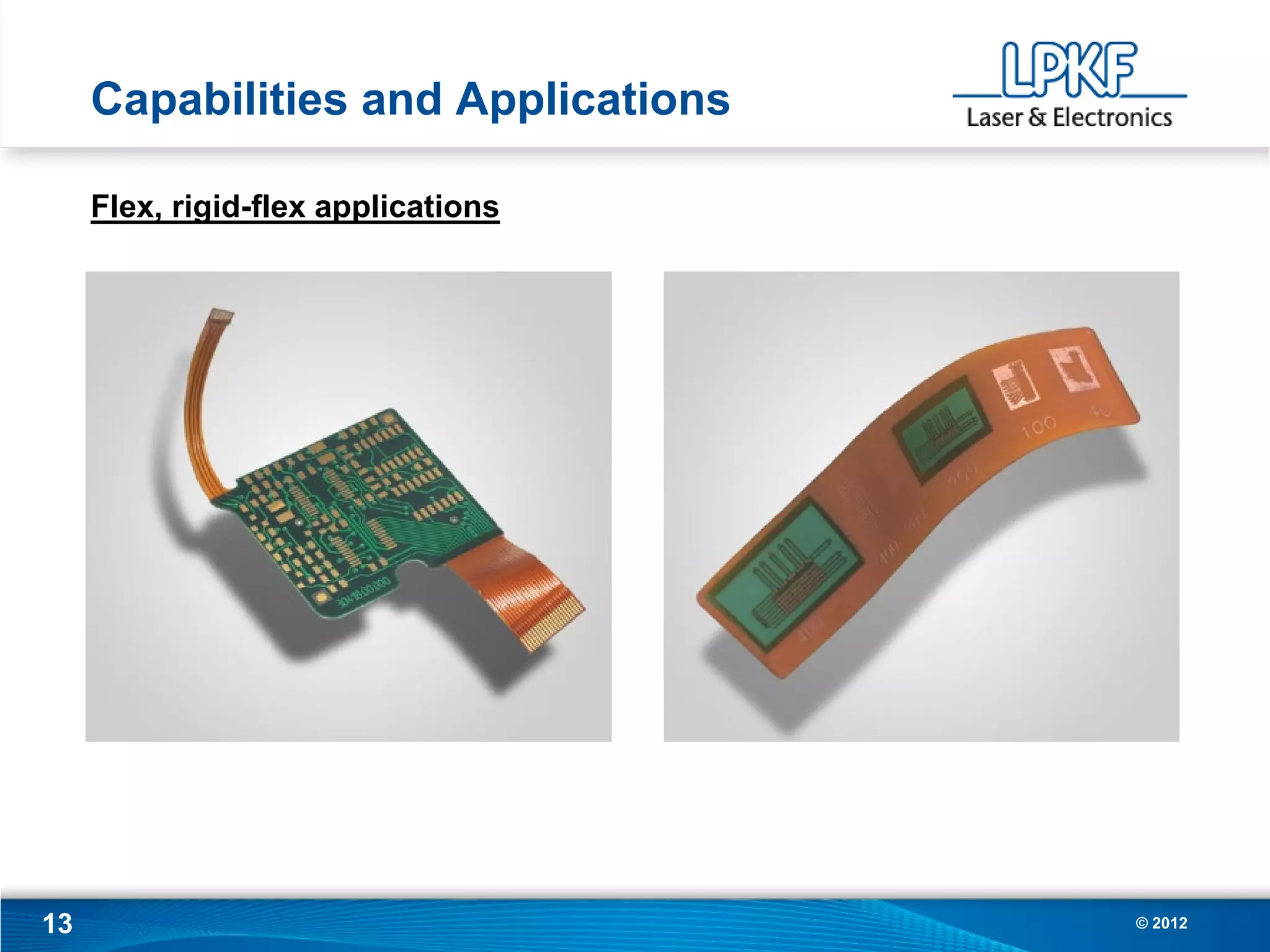

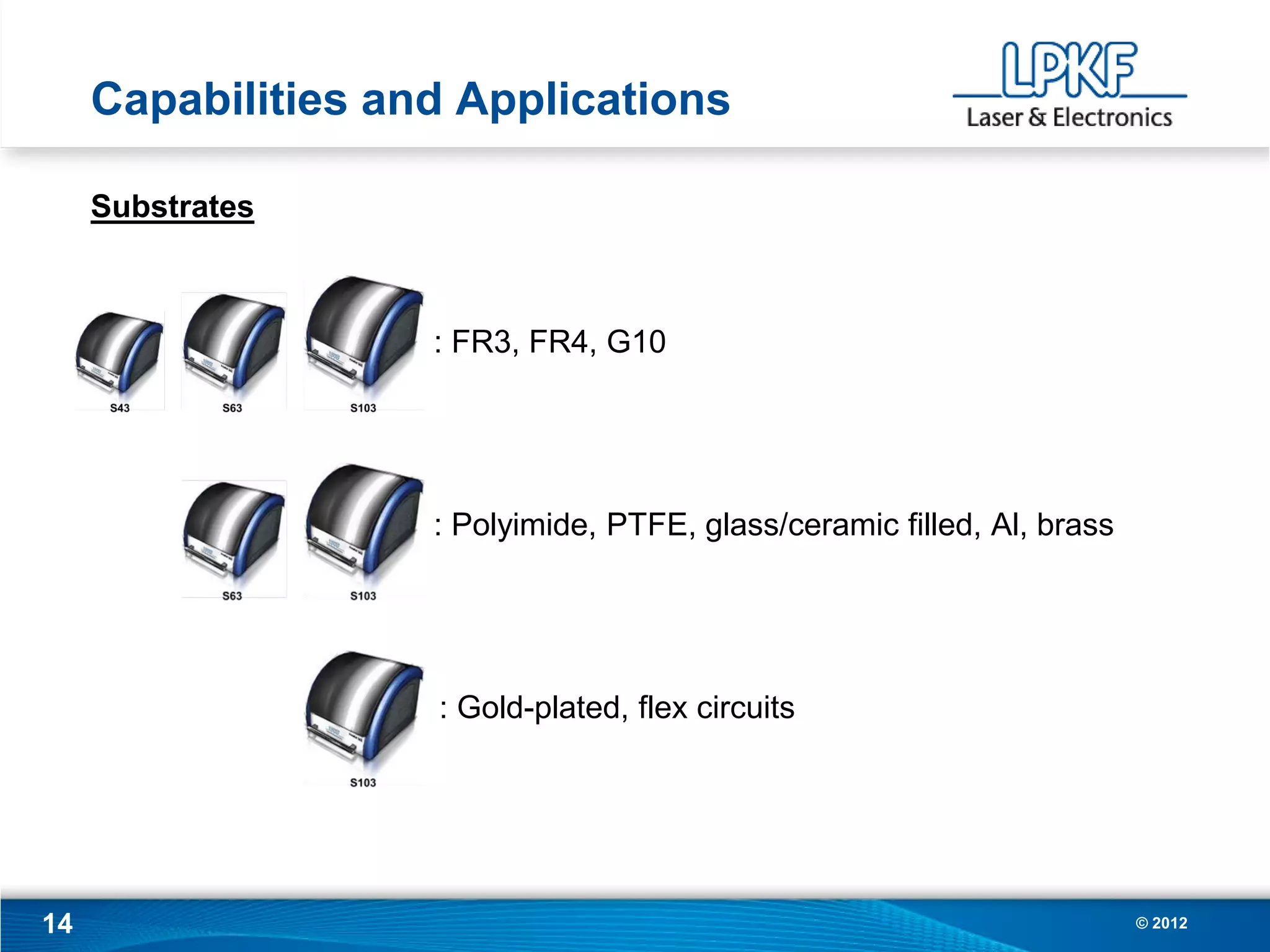

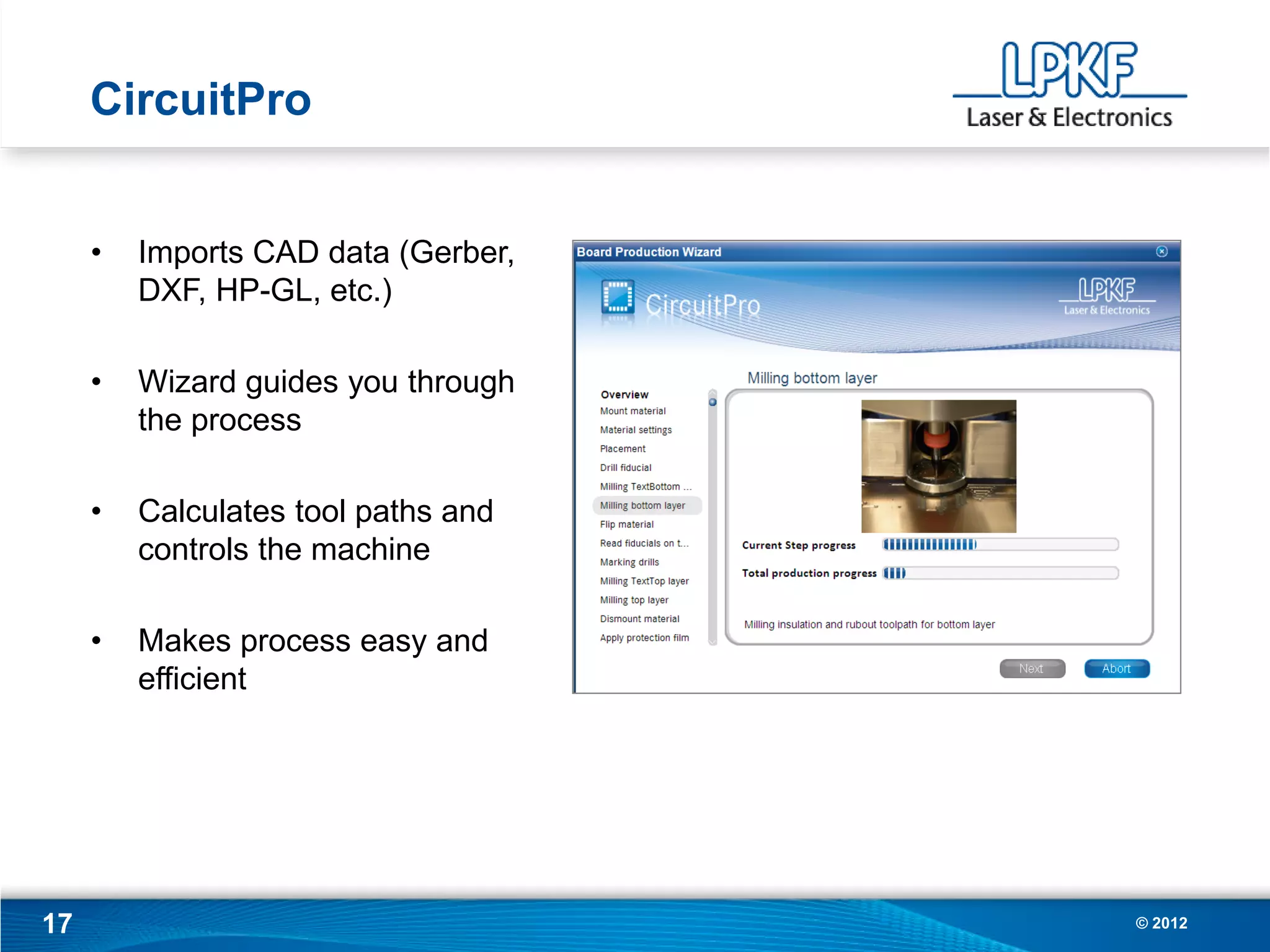

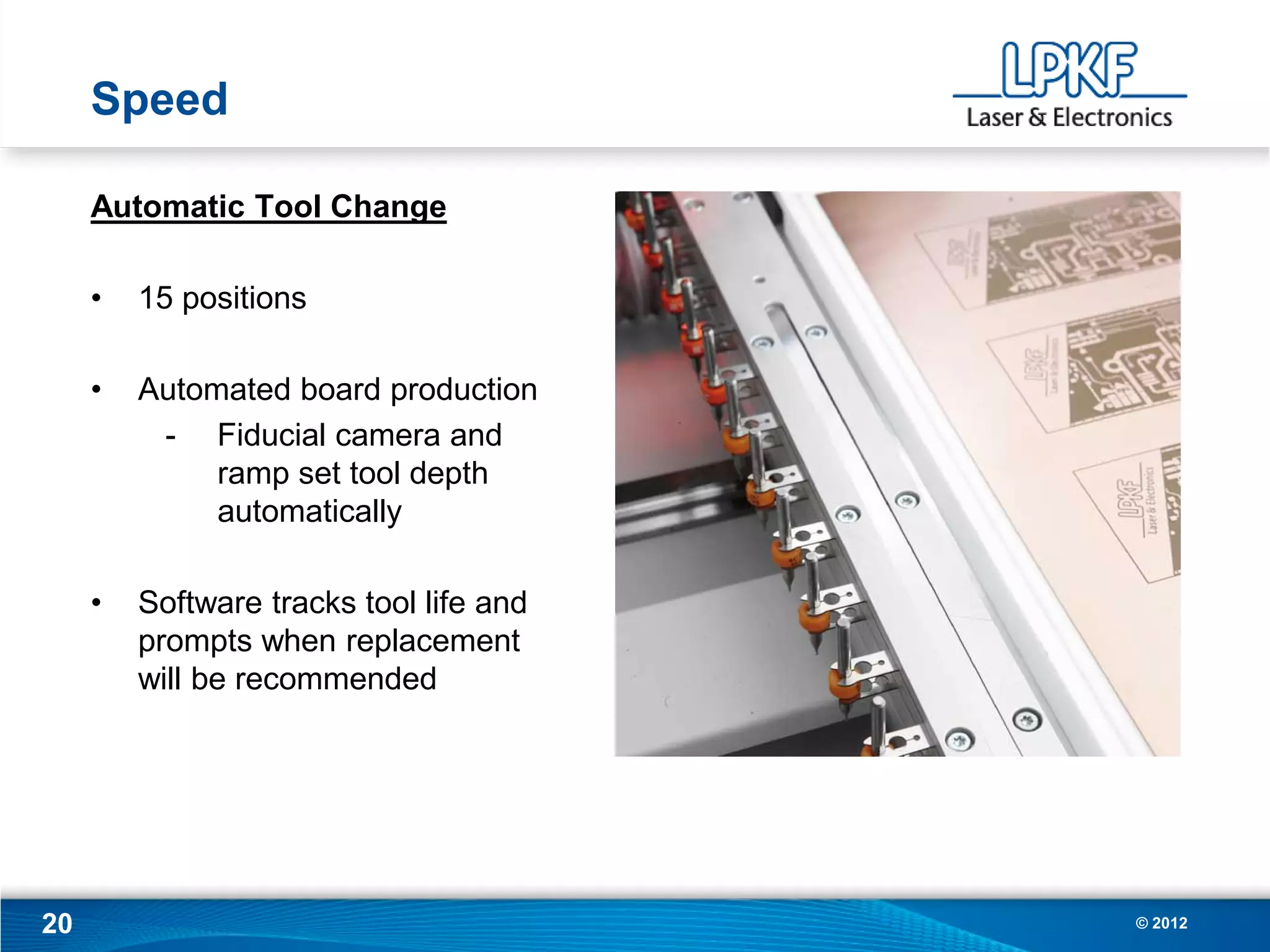

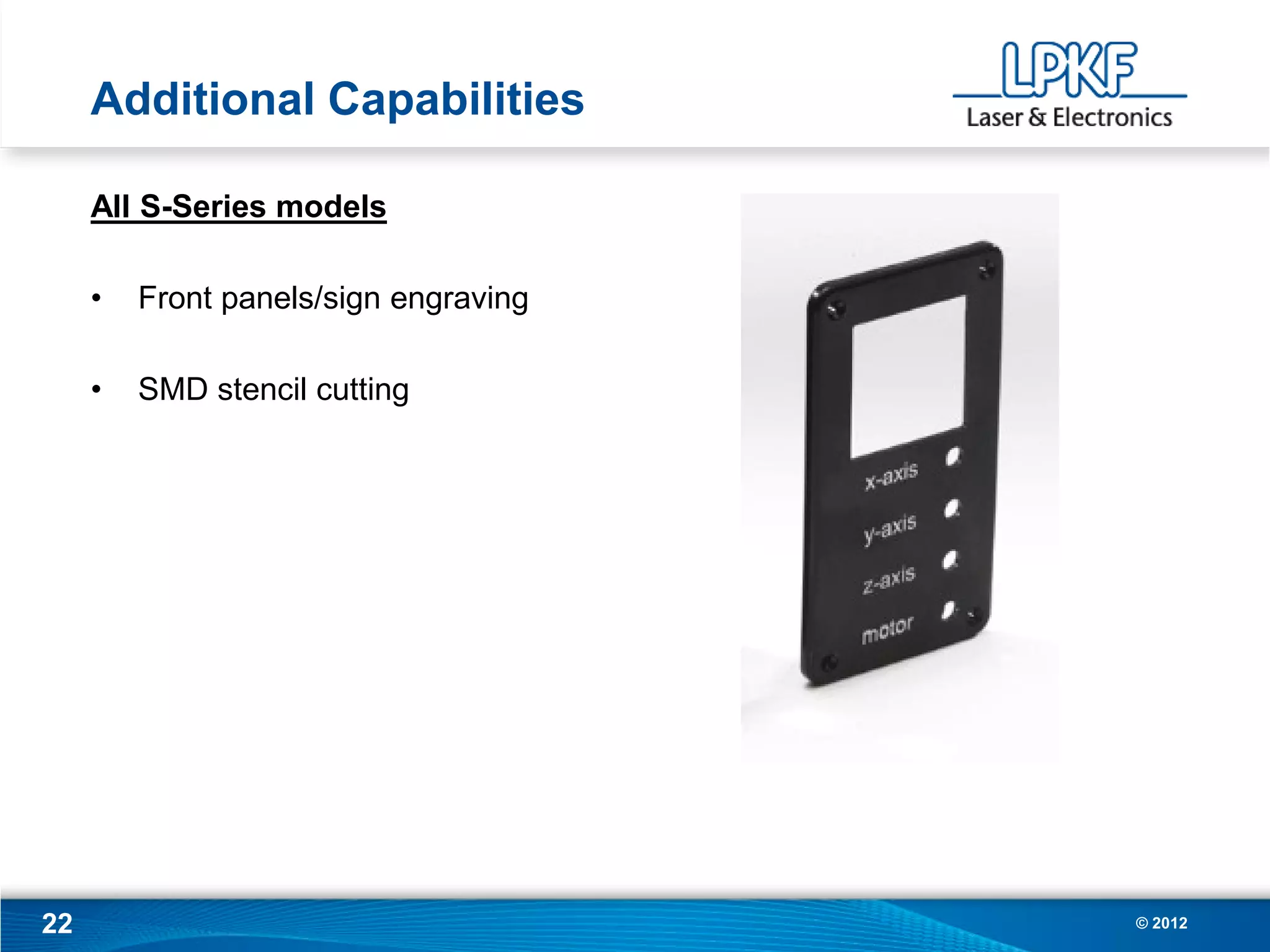

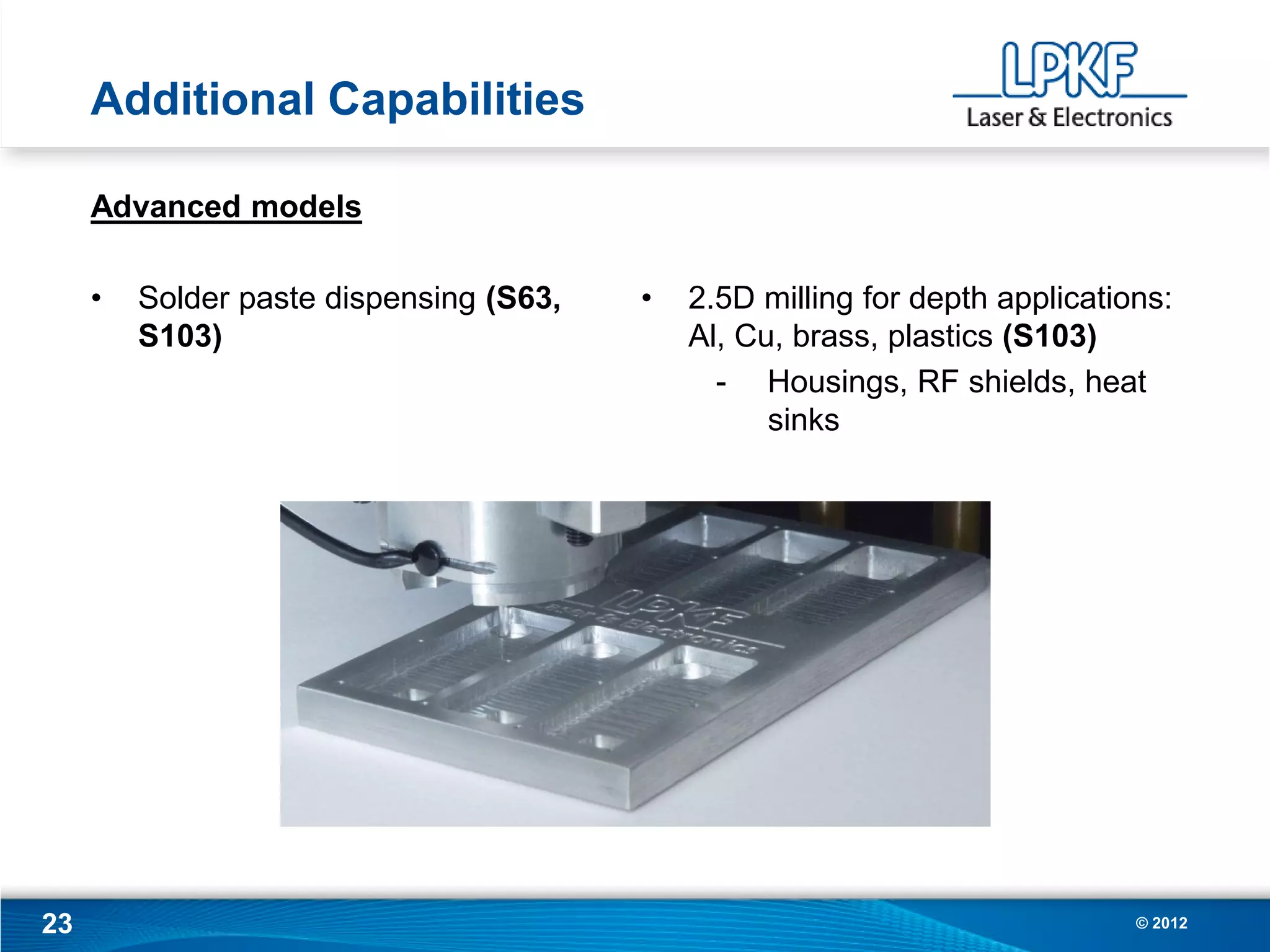

The document describes the ProtoMat S-Series of rapid PCB prototyping machines from LPKF. It discusses the advantages of in-house prototyping and highlights key features of the S43, S63, and S103 models. These include high precision milling and drilling, automated board alignment using a fiducial camera, and speeds up to 100,000 RPM. The systems offer a range of capabilities for applications such as RF and flex circuits. Customers benefit from time and cost savings compared to sending designs out for production.